- Case Study

Haulotte's choice of Zuken's E3.series solution has enabled the optimization of work methodology and a more serene and effective projection towards future developments

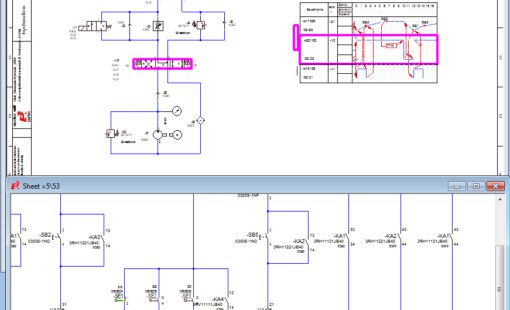

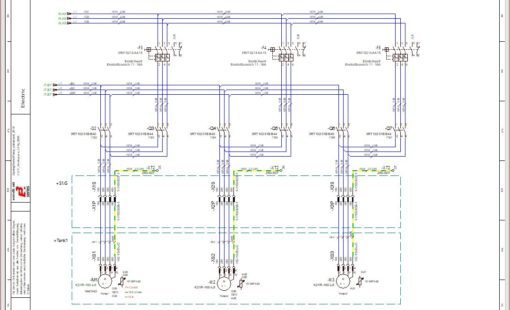

Hydraulic, pneumatic, cooling and lubrication systems activated by electric motors or pumps require integrated handling of fluid and electrical designs. To ensure consistency, representations in both domains need to be interlinked.

With intelligent sheet formats offering easy navigation between electrical and fluid elements. BOMs show only a single instance of combined electrical and fluid elements (e.g. a valve).

Consistent, synchronized representations of electromechanical devices in pneumatic schematics, electrical schematics and installation diagrams through database controlled cross-references.

Design rule checking with optimized functionality for the development of hydraulic, pneumatic, cooling and lubrication systems.

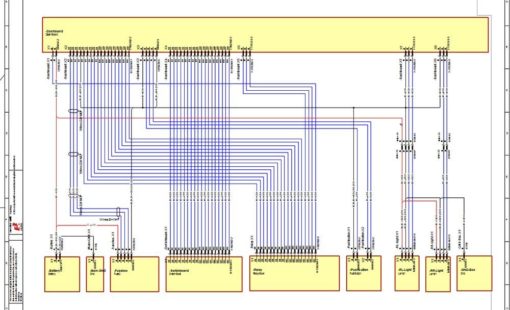

E3.cable extends the functionality of E3.schematic enabling individual conductors to be combined together in the design to form cables and harnesses.

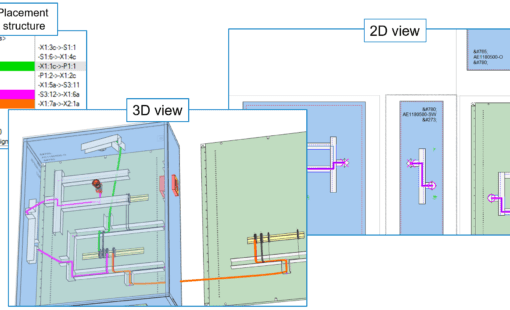

Explore how Zuken’s E3.series integrates seamlessly with leading MCAD tools like Siemens' NX and Solid Edge, Dassault's CATIA V5 / V6 and SolidWorks, PTC’s Creo, and Autodesk’s Inventor for efficient harness design - includes a detailed demonstration of how Siemens NX can be integrated with E3.series.

In this Smart Cabinet Building webinar, we will present you a selection of new functions of the E3.series 2022 release. This session concerns enhancements in E3.panel, as well as the tools for manufacturing automation, in particular E3.CutOut, E3.ExportToKomax and E3.WiringCockpit.

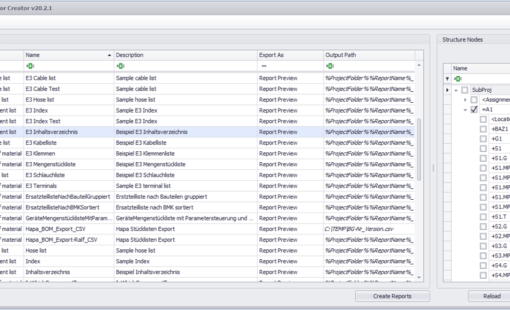

Learn how to create customizable reports within E3.series with E3.ReportGenerator

This webinar will show you how digital product data can support you to develop and produce your control cabinet faster and in a more flexible and economical way.