Prepare and verify manufacturing data

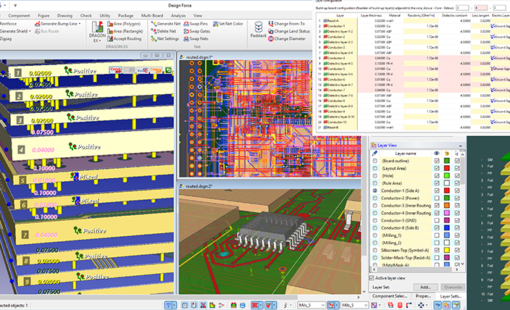

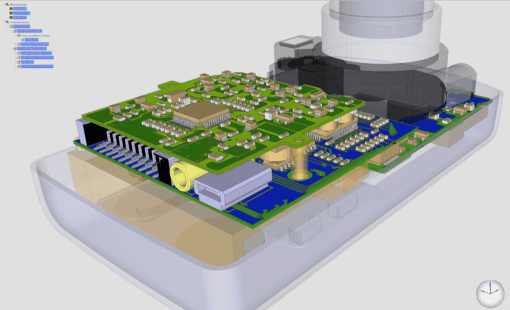

DFM Center enables designers to handle the increasing complexity and diversity of today’s PCBs, while ensuring high final product quality, and accurate outputs for the manufacturing processes. With a robust set of features for data preparation and embedded verification to ensure manufacturing specifications are met, DFM Center addresses the challenges of the manufacturing process.

Prepare and verify manufacturing data

Perform fabrication and assembly checks

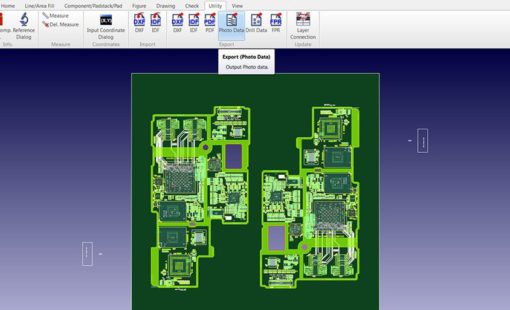

Optimize manufacturability with powerful post-processing functionality

Create comprehensive manufacturing documentation with automatic drill table generation

Find out more about our manufacturing preparation software

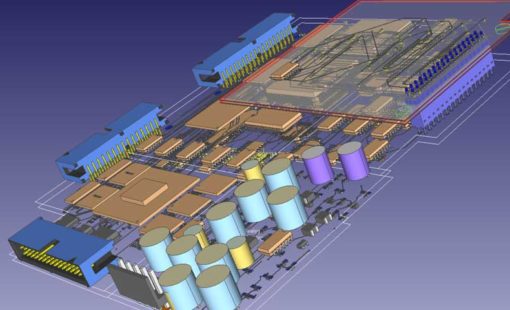

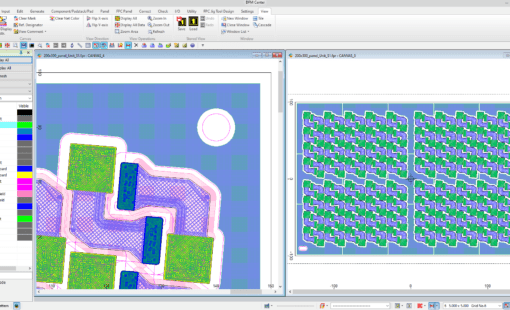

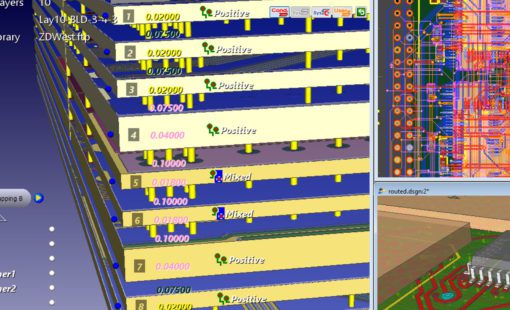

Prepare and verify manufacturing data by paneling up a single or combination of PCBs with real-time manufacturing DRCs.

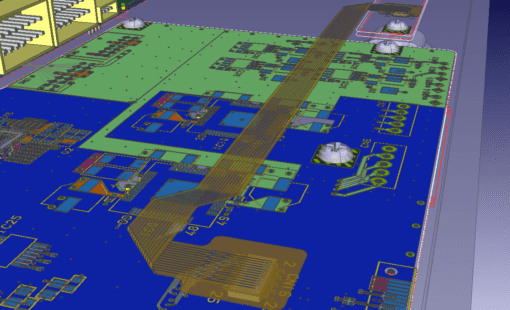

Additional fabrication and assembly checks are applied dynamically based on any manufacturer’s specifications. This allows you to design-anywhere-manufacture-anywhere.

With powerful post-processing functionality, designers apply the necessary additions and modifications to the design, such as automatic copper flooding of the complete panel.

Additional fabrication and assembly checks are applied dynamically based on any manufacturer’s specifications. This allows you to design-anywhere-manufacture-anywhere.

Related Resources

Find out more about CR-8000 DFM Center via our webinars, press releases and more...

CR-8000 advances system-level PCB design with significant enhancements in analog simulation, SI analysis, and intelligent layout and routing

Key development themes for CR-8000 2020 are superior design efficiency, comprehensive system-level design and verification, and support for the latest advancements in packaging technology.

Recent Blog Posts

A customer recently asked me if CR-8000 Design Force could support stretchable flex designs. At first, I found the question odd, until they shared their intent: wearable electronics. The idea of wearable electronic products like head and wrist bands sparked an interesting conversation and piqued my interest.

We’re happy to announce that Speedstack, Polar Instruments’ layer stackup design/documentation tools, can now be directly linked to Zuken’s CR-8000 Design Force and DFM Center.

Related Products

CR-8000 Design Force is the fastest, most effective PCB design solution available today. Design Force enables design teams to layout and verify their designs in the context of a complete system or product.

The CR-8000 ADM system checks that designs are produced in accordance with component mounting and manufacturing specifications early in the design process, and concurrently as the work progresses.