An integrated design solution for interconnecting devices and designing cables and wire harnesses

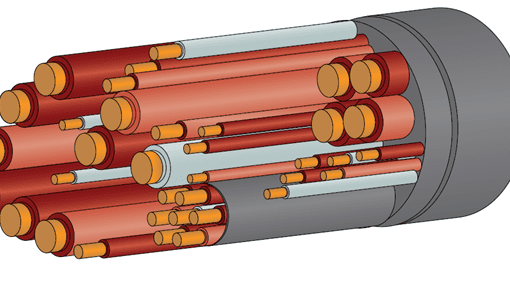

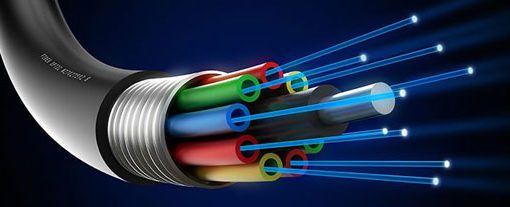

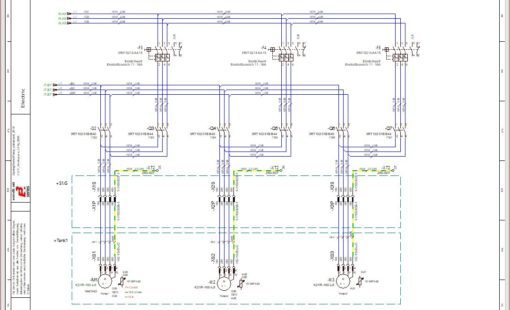

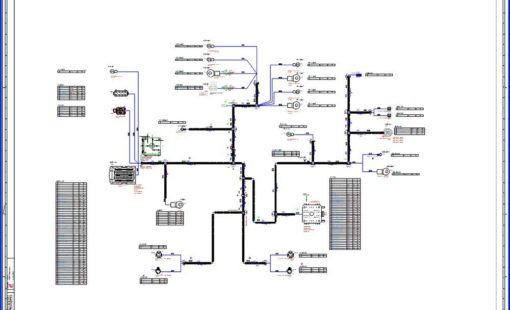

E3.cable is a powerful electrical wiring design software, used for designing and documenting cable plans and wire harness layouts. Extending the functionality of E3.schematic, it enables individual conductors to be combined together in the design to form cables or harnesses. Shielding and twisted-pair structure can also be added to the cables and automatically shown in the schematic. E3.cable is ideally suited for industries developing power and wire harnesses for the automotive, off-highway and special purpose vehicle, and aerospace industries, or those developing field cabling for plant and machinery.

An integrated design solution for interconnecting devices and designing cables and wire harnesses

Intelligent block functionality enabling the representation of dynamic equipment

Hierarchy functionality for flexible top-down or bottom-up design approach

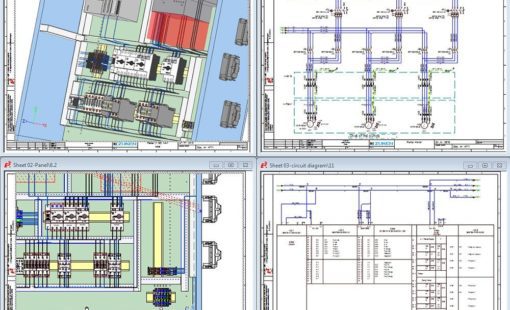

Multiple views of devices for design and documentation purposes

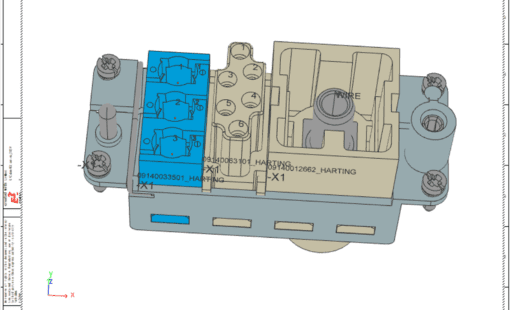

E3.cable supports block functionality for electrical wiring design: blocks can represent components, rack equipment, black boxes, PCBs, and through hierarchy whole systems and sub-systems. Connector pins are dynamically added to the blocks and signal information is displayed alongside.

Views allow alternate documentation of devices such as single-line diagrams, wiring diagrams, and cable plans. For example, connectors can be represented as single pins in the schematic and then as the complete connector in the cable plan. Changes to any of the views, immediately update all other views, ensuring all documentation is synchronized.

E3.cable supports block functionality for electrical wiring design: blocks can represent components, rack equipment, black boxes, PCBs, and whole systems and sub-systems. Connector pins are dynamically added to the blocks, and signal information is displayed alongside.

Views allow alternate representations such as single-line diagrams, wiring diagram and cable plans. Connectors can be represented as single pins in the schematic and then as the complete connector in the cable plan. Changes to any of the views, are immediately updated all related views.

Hierarchical systems and sub-systems can be represented as blocks. Signals and connections can pass between levels and sub-levels. Hierarchy enables top-down and bottom-up design, promotes design reuse and provides project leaders with a system level overview.

Blocks can be integrated with PCB design data. Interface connector and signal information from the PCB system is dynamically added to the blocks in E3.series. Changes to the PCB are re-imported and updated in the block. E3.cable supports most PCB formats and has bi-directional integrations with Zuken’s CR-8000.

See how easy it is to work with E3.cable

Related Resources

Find out more about via our case studies, datasheets and more.

Haulotte's choice of Zuken's E3.series solution has enabled the optimization of work methodology and a more serene and effective projection towards future developments

E3.series 2021 from Zuken delivers enhancements for connector handling, 3D control cabinet design and ECAD/MCAD collaboration.

Zuken Inc., and Electro Magnetic Applications, Inc. (EMA) have entered into a partnership to improve the accuracy of cable harness simulation models for complex electrical subsystems in aircraft and vehicles

E3.cable Related Webinars

This webinar will cover the design of large electrical projects. A vital element of the design process is the tracking of nomenclature, device and cable functions, assignments and placement.

This webinar follows looks at the physical part of the wire harness design process: Routing of the harness in the physical (3D) design space

This webinar covers the logical part of the wire harness design process consisting of creating the wiring diagram and the topology design.

Satisfied customers

Recent E3.cable Blog Posts

Traditional CAD software was once just a digital drafting tool, requiring manual updates and prone to inconsistencies. However, as electrical systems grow increasingly complex, intelligent CAD systems have transformed the design process. Learn more on our blog.

At last year’s Zuken Innovation World Italy, we had the pleasure of meeting a talented team of young engineers from La Sapienza University in Rome. Calling themselves the "Gladiators," Francesco, Matteo, and Domenico are pushing the boundaries of innovation by designing and racing a PreMoto3 prototype in the prestigious MotoStudent competition. Read the whole story on our blog.

The transportation industry never experienced breakthroughs prior to electrification. Now, innovations in motor, control, and battery technology are enabling the electrification of the transportation industry.

From automation to real-time analytics, the Industrial Internet of Things (IIoT) is fundamentally transforming industries. But behind the opportunities lie challenges: Can security, legacy equipment, and complex systems be seamlessly integrated? Discover how smart factories of the future are being shaped and why the IIoT is the key to it all.

In this episode of Mastering E3.series, we explore how to prepare your project for release, covering everything from PDF exports to generating detailed reports. Learn how to utilize the powerful tools within E3.series to create bill of materials and use the report generator.

Learn how to efficiently add components and connectors from the E3.series database to your electrical designs. Explore techniques for managing device properties, working with blocks, and ensuring data integrity in your projects. Perfect for engineers looking to streamline their schematic and wire harness workflows.

Related products and Extensions

E3.panel allows engineers to layout components inside panel enclosures in both 3D and 2D. Intelligent automatic snapping points allow parts to be easily placed in their correct location.