Machinery - Cabinet & Panel

Connecting Electrical Design to Manufacturing

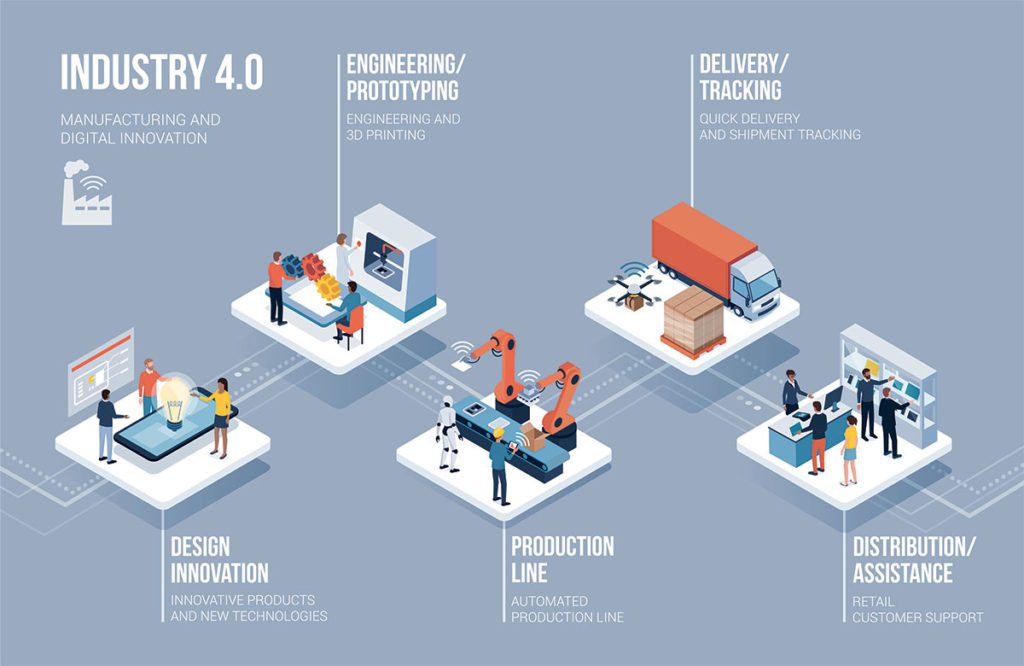

Zuken’s E3.series design platform improves the efficiency of the manufacturing and assembly processes of electrical designs. The ability to capture design intent and manufacturing constraints early in product development is unmatched and provides a competitive advantage.

The intelligent data-driven platform connects to leading manufacturing automation platforms to enhance the production cycle. Existing business systems like ERP, PLM, and PDM platforms can be digitally connected for a holistic development process.

Industries

Automotive - Systems & Wiring

Aerospace - Systems & Wiring

Special Vehicles - Systems & Fluid

Capturing Manufacturing Details

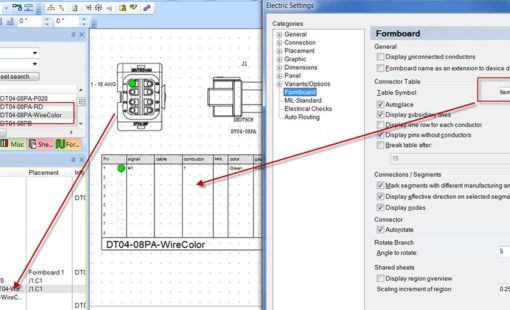

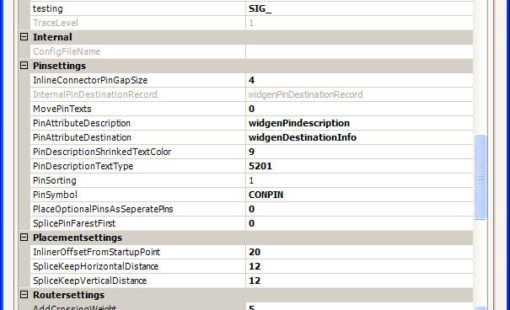

The intelligent library encourages capturing physical and technical requirements early in the design process for enhancing assembly and manufacturing. The application references wire size, wire termination details, terminal crimp, mounting details, cable protection, and other essential details from the library.

The DRC engine cross-checks the design against preset manufacturing feasibility and standards for the engineers. Active checks highlight and stop errors during the design process, while passive checks are available for activation to ensure accuracy.

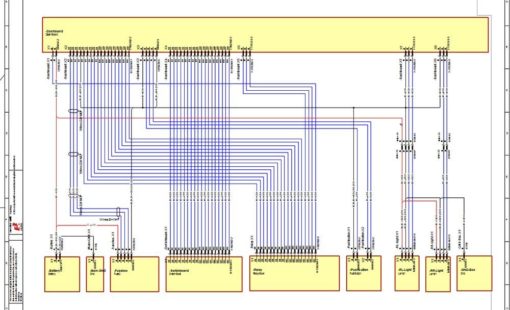

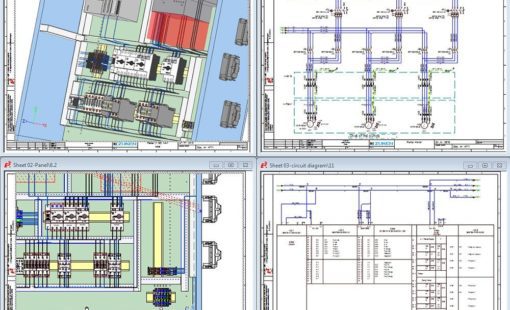

Cabling and Wiring Cabinet Design

Configurable Design Methodologies

The built-in configuration management system empowers designers to create plug-and-play designs. Quickly capturing reusable designs improves consistency and reduces rework. All design types, including schematics, wire harnesses, and electrical cabinets, are available for dynamic configuration.

Options and variants allow different inclusive and exclusive systems and components to be used.

Advanced configuration management options supplied with DS-E3 enable teams to manage and produce a design with part number variations. Context-driven design reuse enables simple as well as complex Boolean logic-driven configuration management. Automatic updates to reports and documentation eliminate errors and ensure consistency across projects.

Diagram Generator Configuration Management

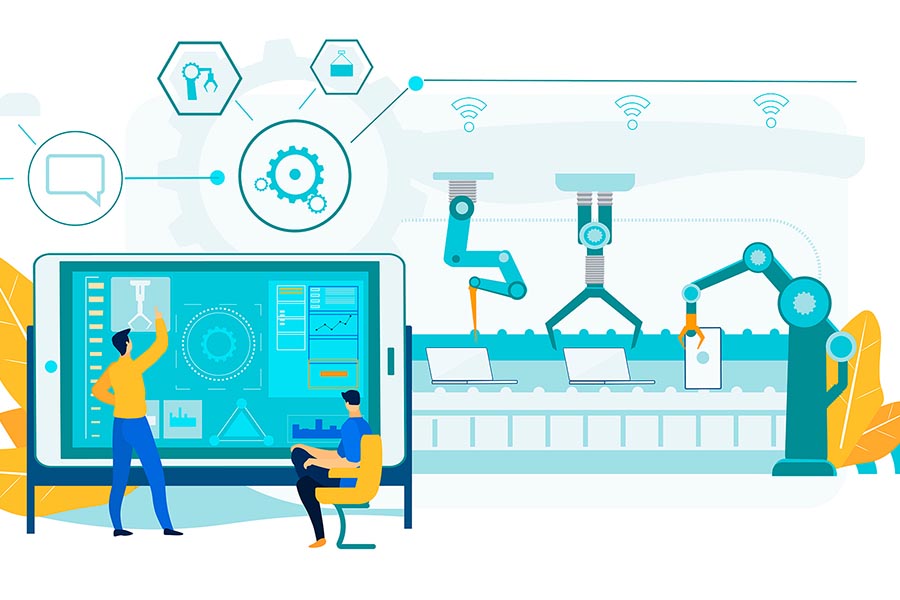

Automated Assembly Processes

Intelligent design data and accurately capturing design intent are the foundation for taking advantage of digitally augmented assembly processes. Automated reporting and documentation options simplify the product assembly and service process.

The always up-to-date design data ensures consistency and quality across the assembly process. Automatic terminal configuration, labeling information, cut-out, layout, keep-out area marking, and other vital characteristics, can eliminate manual error-prone processes.

Step-by-step instructions and sub assemblies can be created with other vital characteristics that can eliminate manual error-prone processes.

Wiring Harness Design Cabinet Design

Automated Manufacturing Processes

Transform manufacturing with the help of intelligent wire harnesses and control cabinet design data. Get accurate wiring schedules, terminal plans, wire lengths, mounting locations, cut-out data, and restrictions to drive automated manufacturing processes.

E3.series automatic wire processing creates accurate digital data that drives highly automated wire cutting and processing machines from vendors like Schleuniger, Komax, and Argus.

Automatic labels and markings can be designed via configurable output formats connected to leading labeling, marking, and other printing options for wires and devices.

Drilling and milling machines can be automatically driven from E3.series panel data to help improve accuracy and consistency.

Harness Builder Cabinet Builder

Intelligent Manufacturing Work Instructions

E3.series simplifies the time-consuming process of creating work instructions by using engineering data. Create, release and manage work instruction packages to define the wire harness building process. The work instructions creation process utilizes the in-depth manufacturing data captured during the design phase.

Pre-built customizable work instruction templates ensure consistency across projects. Auto-actions trigger repeatable custom automation routines to assemble relevant assembly instructions. The combination of accurate design data and configurable reports helps improve quality and increases productivity.

Reports are created automatically, reducing errors and timely manual paperwork creation.

Harness Builder

E3.series FAQ

Zuken’s E3.series is a leading single platform solution to take a design from concept to manufacturing. It is a reimagined wire harness, control cabinet, switchgear, and cabling systems design solution.

E3.series encompasses all aspects of electrical design like functional design, detailed schematic, wiring diagram, cabinet layout, formboard, reports, and manufacturing documentation.

Learn more

Related Products

- Products

E3.cable extends the functionality of E3.schematic enabling individual conductors to be combined together in the design to form cables and harnesses.

- Products

E3.panel allows engineers to layout components inside panel enclosures in both 3D and 2D. Intelligent automatic snapping points allow parts to be easily placed in their correct location.

- Products

Harness Builder for E3.series enables wire harness manufacturers to create accurate quotations and comprehensive manufacturing documents, and to drive wire preparation, assembly and testing machines.

- Products

E3.WiringDiagramGenerator automatically generates schematics or wiring diagrams for development, service, and after-sales.

- Products