Capturing Manufacturing Details

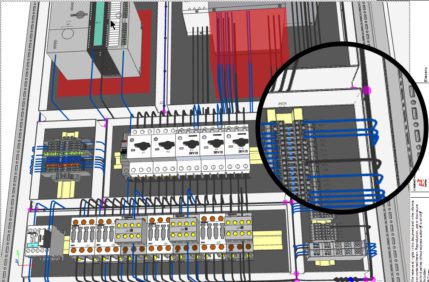

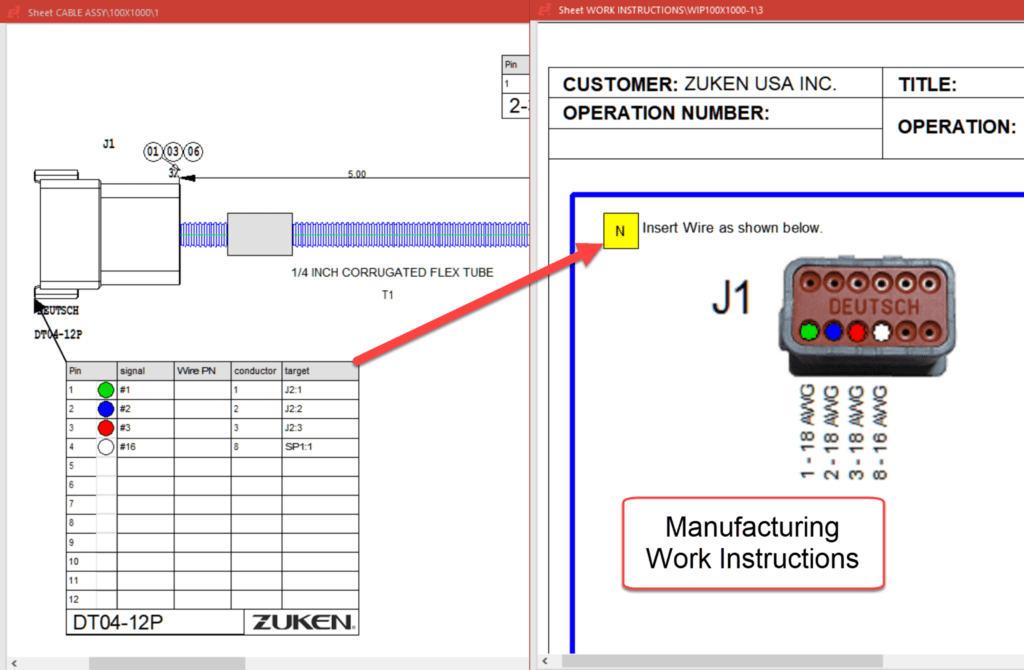

The intelligent library encourages capturing physical and technical requirements early in the design process for enhancing assembly and manufacturing. The application references wire size, wire termination details, terminal crimp, mounting details, cable protection, and other essential details from the library.

The DRC engine cross-checks the design against preset manufacturing feasibility and standards for the engineers. Active checks highlight and stop errors during the design process, while passive checks are available for activation to ensure accuracy.