Library and materials data management

The traditional practice of mechanical, electrical and electronic engineers working in silos – then consolidating efforts late in the development process – is no longer viable for successful companies. Zuken offers a portfolio of scalable domain data management solutions for PCB and electrical/fluid design plus a range of solutions that integrate design and domain data management into the PLM and ERP world.

Zuken’s DS-2 is a mature, cross-disciplinary engineering data management platform developed in partnership with more than 3,000 leading companies worldwide. DS-2 has evolved from an electronics data management product into a technology platform capable of managing electronics design data from CR-8000 (using DS-CR) and electrical data from E3.series (using DS-E3) embedded into their respective ECAD environments.

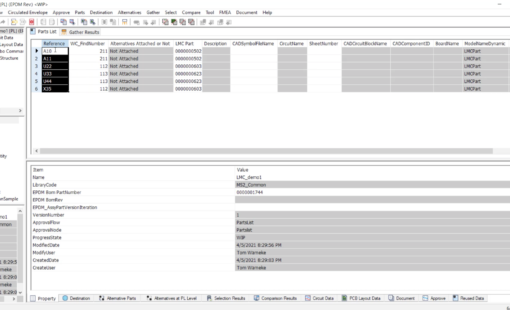

With DS-2, Zuken provides a domain-specific data and process management solution for electrical and electronic engineering. It manages and consolidates CAD component libraries, material information, schematic and designs data in a controlled release and revision process. DS-2 is open for integration with all major PLM and ERP systems via SOA-based plug & play connectors to enable a true electro-mechanical data model.

Library and materials data management

Design data management

Configuration management

Change management

See how to get back time for thinking and designing and spend less time on administrative tasks

Find out more about Zuken's advanced library and design data management solutions

DS-2 provides a single-source environment for all component information within the engineering process.

Track component versions through the component lifecycle enabling component updates throughout the product lifecycle, with full tracking and transparency.

Manage design data, related documents, simulation data, enclosures, parts lists & CAM data.

A built-in change management process provides a detailed documentation of each design or document change, such as modifications to the specification, customer change, and obsolescence.

By unifying all engineering data into one environment and controlling synchronization to local or international development teams, DS-2 provides a single source of truth in a global environment.

Select the right products from the DS-2 platform

Zuken’s engineering data management platform DS-CR has been created to support the specific demands of PCB design data management. It combines multi-site library, design data and configuration management into a unified engineering environment.

Check out our latest webinars, white papers, blog posts, tech tips & more

Read about our latest Data Management announcements