Zuken Innovation World (ZIW) has been our annual chance to meet and collaborate with our customers and partners en masse for many years. After a two-year COVID-driven hiatus, we’re finally back with a LIVE ZIW event on June 6-9 in San Antonio, Texas. This event is an event for our customers to share their experiences with our tools, it’s also an event that allows us to share the new functionalities in our latest product releases and take a deeper dive into some of the more advanced features. Just as a sampling of our agenda, let’s take a look at some highlights of our PCB Design and Data Management Track, and a few examples of the content you can expect to see at ZIW 2022.

Improved Design Efficiency

Viasat will share the design efficiency improvements that they have discovered in their implementation of Zuken’s DS-CR and CR-8000 tools in their PCB design and Design Data Management flow. DS-CR is a tool that allows for the control of WIP data management, detailed access of the component data, push-button documentation data generation, where user information, and many other features to ensure that the PCB design data is always up to date.

Coming from a Windows-based WIP data flow to a flow with an intelligent wrapper for this data ensures quick access to the needed information. In this time of distributed workforces, that access is essential. It’s also recognizable via DS-CR as to what the most current version of the data is and what state in the design process the data is at. This class will also explore additional functions of the tools including library creation and communication improvements. There will also be some exploration of CR-8000 Design Force’s capabilities for comparing different versions of designs. This can be especially useful to ensure that the intent of design change was met as well as to verification of the current state of a design.

PI and SI in CR-8000 Design Force

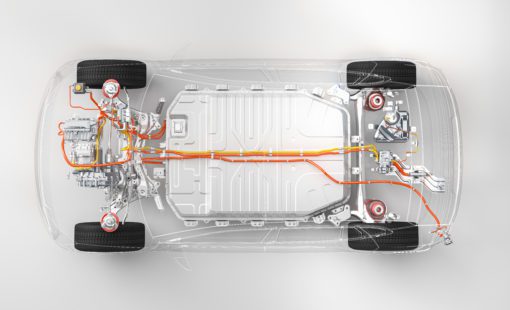

In the ever-advancing requirements and restrictions being placed on modern designs, the margin for error is constantly shrinking. The power domain is almost under siege in that the demands for optimized power distribution and minimization of components associated with stabilizing this power are in a push/pull relationship for control. Zuken’s built-in capability to evaluate the power distribution and performance is critical in the drive to balance these requirements. Our embedded PI (power integrity) tool is integral to being able to understand and react to a design’s power domain needs.

In our next class example, Wilmer Campanioni of Zuken will take attendees through the mechanics of running SI (signal integrity) simulations in our CR-8000 Design Force product. SI requirements are putting additional requirements on design challenges. As signal speeds and timing synchronizations continue to evolve there is a need to characterize these requirements in the constraints and perform frequent analyses to see where your designs stand. Often times we have customers that only rely on signoff level simulations. Unfortunately, this drives a significant effort to incorporate changes if the PCB is mostly complete when issues are discovered. Leveraging the built-in SI capabilities ensures that the impact on the cycle time and thus the development cost is kept to a minimum. As with any advanced tool, the setup is critical to obtaining accurate results. This is the area that Wilmer will focus on, education on the driving factors to get the best results out of these powerful capabilities.

PCB Autorouting in CR-8000 Design Force

For our final example, let’s discuss Andy Buja’s class on PCB Autorouting in CR-8000 Design Force. Autorouting can have a tendency to be underutilized. A user selects the entire design area, launches the router, and then is displeased with the result. We have a solution that addresses the problem AND the underlying methodology: Routing Consultant. Launching the Routing Consultant results in an evaluation of the pertinent items that the router will consider; line widths, spacings, via grids, pin pitches present in the design, and so on. When a user reviews these results he then has the needed information to optimize/edit the design for optimum results.

There is also the concept of routing strategies that allow the user to set the parameters of the various routing passes and maximize the results that follow. From a methodology perspective, maybe autorouting the entire design is not of interest. In that case, the user can leverage the tool for more simplistic tasks. Maybe use it to run the escape routing on your high pin count devices and set it for spiral vias. Then in a few short setting selections, an operation that is normally time-consuming when performed manually now takes only a brief time.

Since CR-8000 Design Force leverages multi-core and multi-threading processors, the designer can continue to work on other areas of the design while on, (or more), auto-routing processes are being executed. We’ve found that once the user has some success using the router for even partial areas of the design, they’re then more likely to exercise the tool for broader swaths of the design landscape. Andy will be talking about these topics and more on auto-routing in this class.

See you in San Antonio!

The above-highlighted classes are just a few examples of the content we have planned for our PCB design and data management track. There’s so much more than this on the schedule. If you’d like to review the agenda, more information can be found here!

ZIW PCB and IC Packaging Design TrackWe’re really looking forward to this event. We always enjoy the time with the Zuken community. One of the best aspects of ZIW is that it gives us time to learn from each other. The customers can join us at the Expert Bar and discuss their challenges. Our team can suggest solutions and at the same time, come to a greater understanding of their design challenges. One of the biggest benefits of this is that it gives us time in a relaxed environment to share knowledge and gain information that we can then share with development to continue our path of tool evolution to meet our customers’ current and future needs. It’s going to be great to have this event at long last and we look forward to seeing you there.

Related Products & Resources

- Blog

- ZIW

- Press Release