A two-year global pandemic meant most events were virtual. This year ZIW (Zuken Innovation World) is live in San Antonio, TX. Looking at the agenda for ZIW 2022, the wire harness design process and manufacturing options are among the most exciting class topics. The translation of MCAD data to ECAD and the subsequent 3D harness flattening process is progressing faster, simpler, and with more detail. At the same time, digital tools are driving the wire harness assembly and production process to new productivity levels. For instance, the digital formboard options are reimagining the wire harness drawing and their application for assembly.

Looking at these solutions raises a few questions:

- Are they competing to be THE solution to greater productivity and quality?

- Does a digital formboard make MCAD-ECAD 3D harness flattening obsolete?

- Where should companies first invest their time and resources?

The short answers are yes, no, and it depends. However, the accurate picture is a little more complex. Let’s look at the details to get some clarity.

MCAD-ECAD Harness Flattening

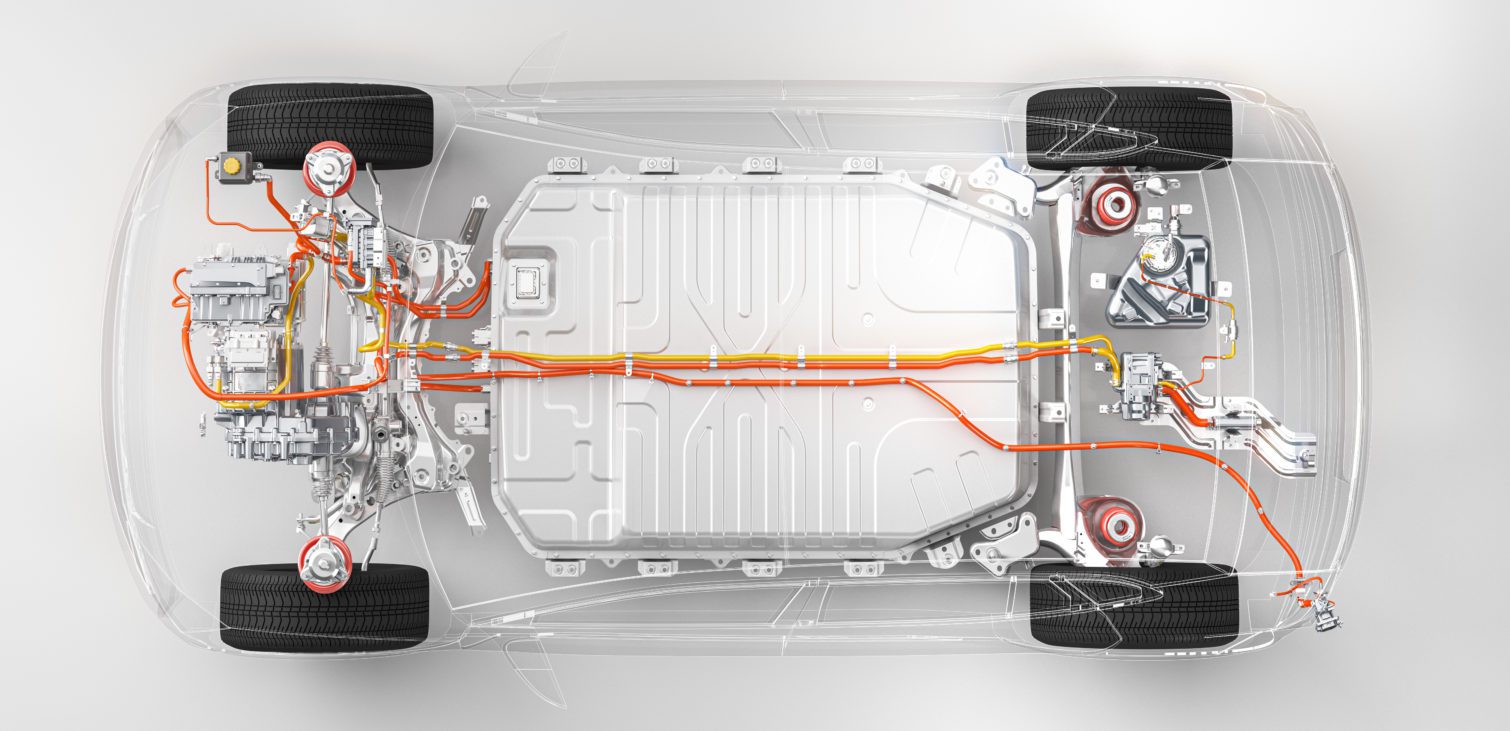

We know MCAD systems own the physical model, and the ECAD systems own the electrical data. As a result, the wire harness is often impacted the most by this duality. Typically, the wire harness in 3D MCAD tools is only a graphical representation. The 3D harness flattening process is vital to ensure the documentation accurately captures the details required for wire harness assembly and production.

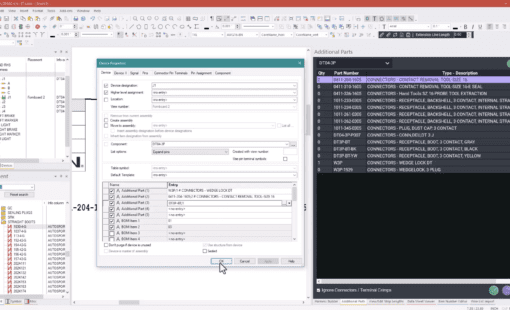

Teams use various harness flattening techniques to find practical solutions to transfer the information from MCAD to ECAD. Not surprisingly, engineering teams employ many processes to manage the data across multiple disciplines. The approaches vary by effectiveness, with some teams creating a streamlined path to connect MCAD and ECAD teams. In contrast, a few are sacrificing the electrical details to manage their wire harnesses in the MCAD tools. The wire harness assembly teams require clear and precise details to maintain quality standards while meeting deadlines. For instance, the formboard drawings must provide relevant information about connectors, wiring, lengths, accessories, wire treatments, labels, and more. Without the right tools, it can be a time-consuming process. Notably, the best solution up to this point has been to use applications such as Zuken’s E3.series to produce detailed wire harness manufacturing drawings.

The ZIW class by Khang Nguyen, ‘MCAD to ECAD Harness Flattening Process,’ describes a streamlined process to extract an MCAD harness model and flatten the 3D harness to create a detailed formboard quickly and easily.

Digital Wire Harness Assembly

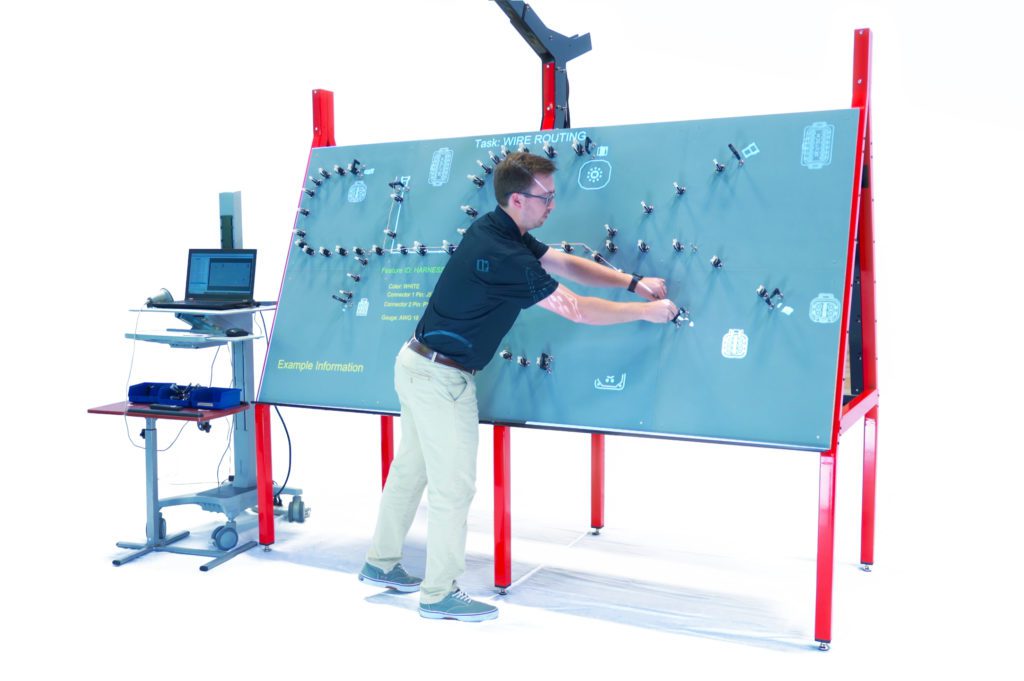

Now consider that the latest digital formboard technology is transforming the wire harness assembly process. The concept of a digital thread seamlessly connecting engineering and manufacturing is exciting and enticing. The data from design tools can feed directly into an electronic format providing step-by-step instructions for the assembly process.

Companies like HarnessWorks are transforming the digital landscape by projecting the formboard instead of printing drawings. Not only that, but the solution also provides options for contextually displaying relevant information to the assembly technicians. So, a drawing does not need as many details, but capturing product information during the design process is vital. Moreover, the transformation of the drawing to an augmented reality projection is seamless if you are using the right tools. For instance, Harness Builder for E3.series directly exports the logical and physical harness details to the HarnessWorks platform to enable digital assembly. Importantly, the 3D harness flattening process feeds vital information vital into the design to streamline the digital transformation harness assembly process.

The ZIW class by Roger Richardson, ‘Extending the Digital Thread: How Digital Tools are Transforming Wire Harness Assembly,’ will provide insight into improving knowledge transfer from an engineer to a technician. The class will also describe the impact of user experiences in software and hardware solutions in automating manufacturing processes. You will learn how to influence your team’s tools to improve performance, productivity, and continuity.

Join us in person in San Antonio, Texas, from June 6 – 9 for ZIW 2022.

Zuken Innovation World

Each year Zuken hosts Zuken Innovation World, an industry event that welcomes customers, partners, and industry professionals to participate in a technology and user conference supporting the mission to network, learn, and innovate. In 2022 ZIW will be co-located with Integrate22, Vitech’s inaugural event aimed at fostering dynamic, vibrant discussions around all areas of digital engineering, with a focus on open and connected solutions.

An exciting and varied agenda features multiple tracks with classes covering product training, customer and partner case studies, design best practices, and forward-looking topics. The Technology Showcase, combined with the Zuken and Vitech Expert Bar, provides an opportunity for one-on-one interaction with participants in an energetic environment.

Sign-up early to save your spot, early bird prices end on April 22nd.