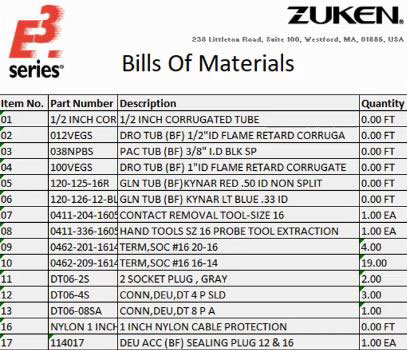

The E3.toolbox Bill of Materials provides versatility by opening up B.O.M. to easy and fast customization. The B.O.M. creation options are greatly enhanced with options for a single drawing page, an entire project, a selection of items or an assembly. The two standard output options for drawing sheet or in Microsoft Excel are simple and effective. The on-page B.O.M. is created using a customizable header and row symbols where text types can be added to display desired attributes. The Excel output can be customized to include all major attributes with a drop-down list from your library.

Customization and standardization are achieved without any custom programming requirements reducing overhead and turnaround times. Alternate part numbers for devices, connectors, and assembly parts improve decision making during the purchasing and assembly phases. The productivity factor is further boosted with the options for combining or separating assemblies and assembly parts.

The B.O.M. can be created top-down or bottom-up with various options to control the output type required. For example, users can choose whether to count up pins on connectors that are unused. Item No. balloons are created automatically to assist with compatibility with different drawing styles and standards.

Item No. balloons are created automatically to assist with compatibility with different drawing styles and standards. The on-page BOM is created using customizable header and row symbols where text types can be added to display desired attributes. The Excel output can be customized to include all major attributes with a drop down list from your library.