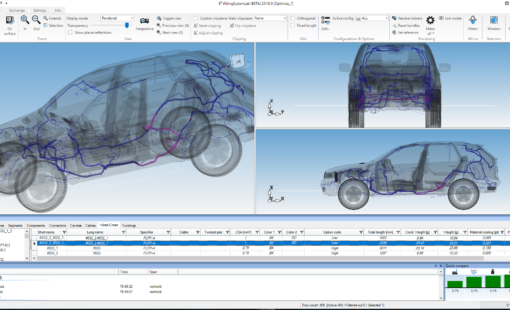

Starting Design from Excel

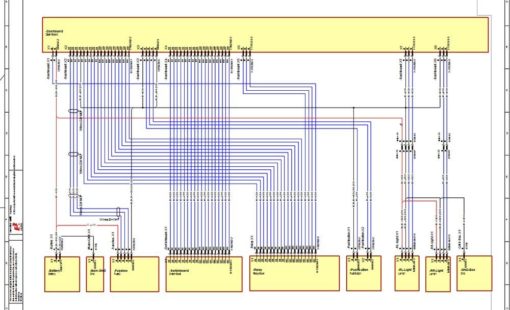

Jump-start, the design process, using from/to connectivity data or PCB pinout stored in excel or CSV files. Design teams often receive connectivity data, wiring details, and block configuration internally or from suppliers and OEMs. Manually entering or recreating the data is a common source of errors.

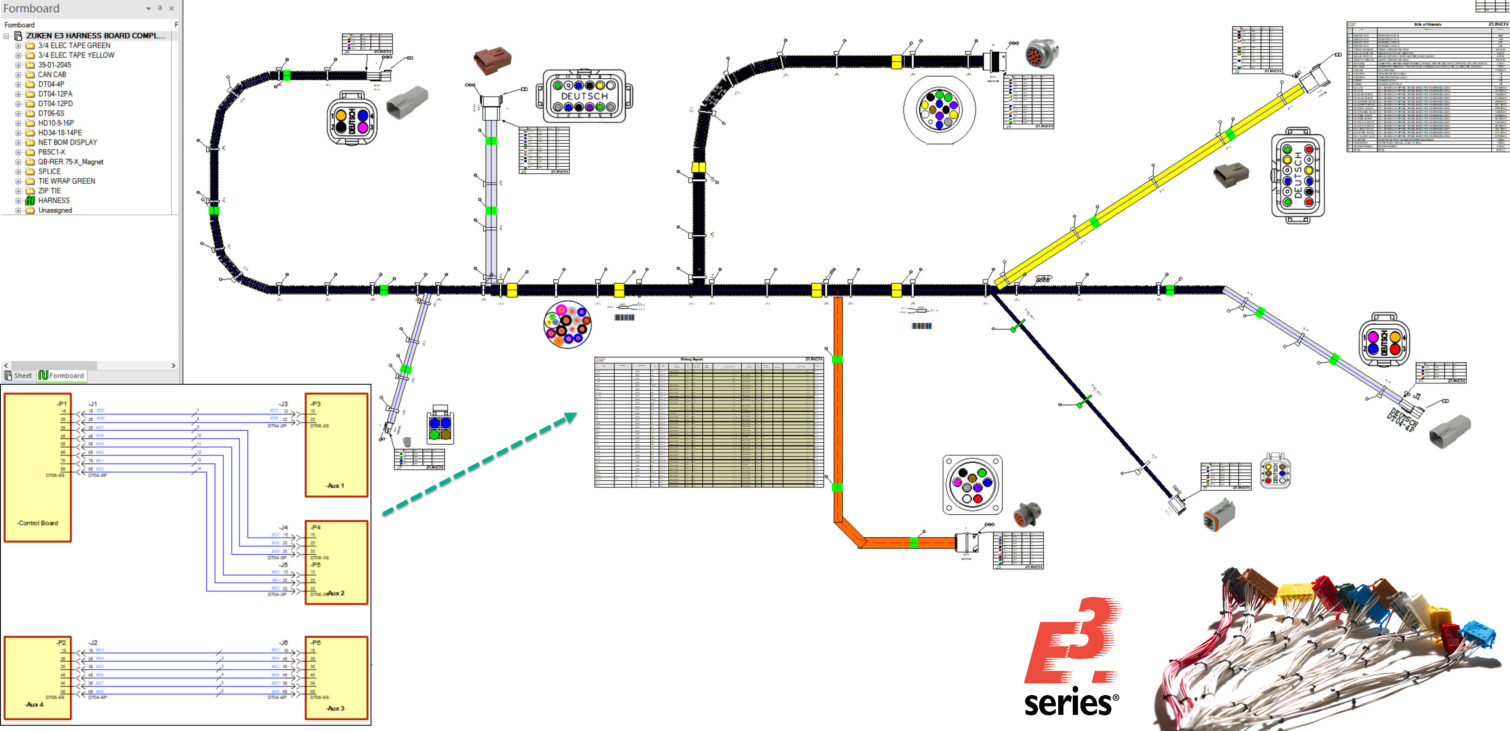

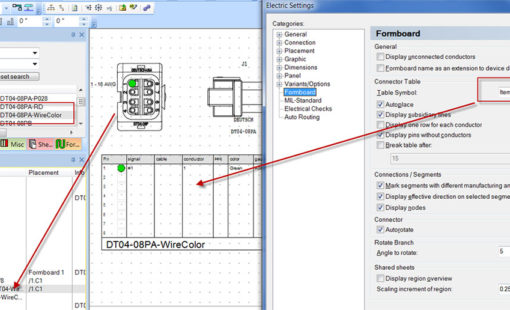

E3.series provides users the flexibility to define and map the column configuration without increasing the complexity of the import process. Linking PCB blocks in the project with external files enables engineers to update design data interactively, avoiding rework.