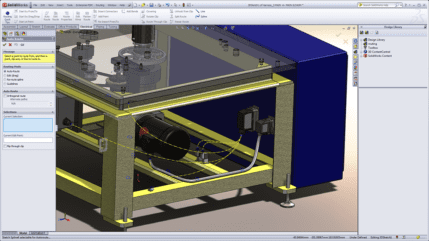

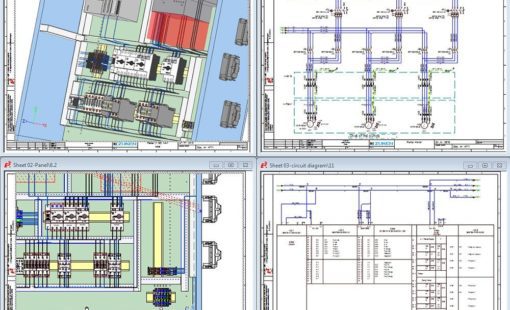

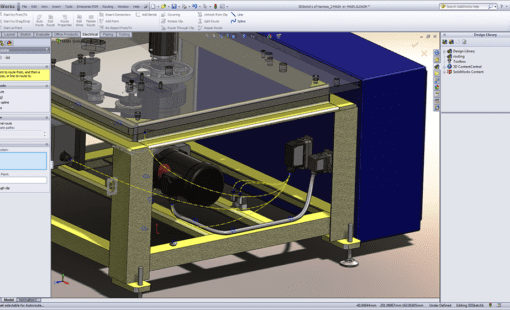

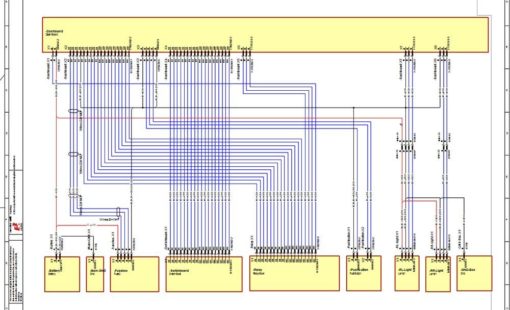

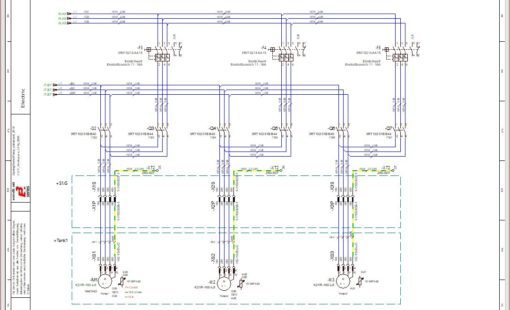

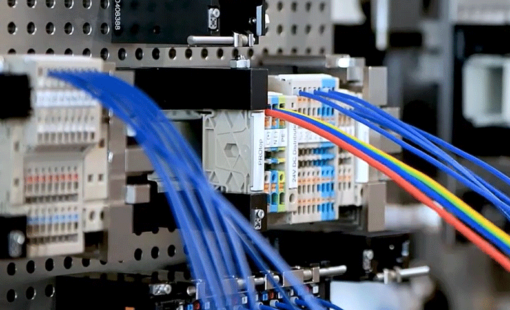

The engineering phase is decisive for the success and efficiency of control cabinet production. An intelligent coordination of digital product data and networked engineering tools provides a solid basis for efficient assembly.

Dr. Bernhard GornyHead of Product Lifecycle Data Management, Weidmüller