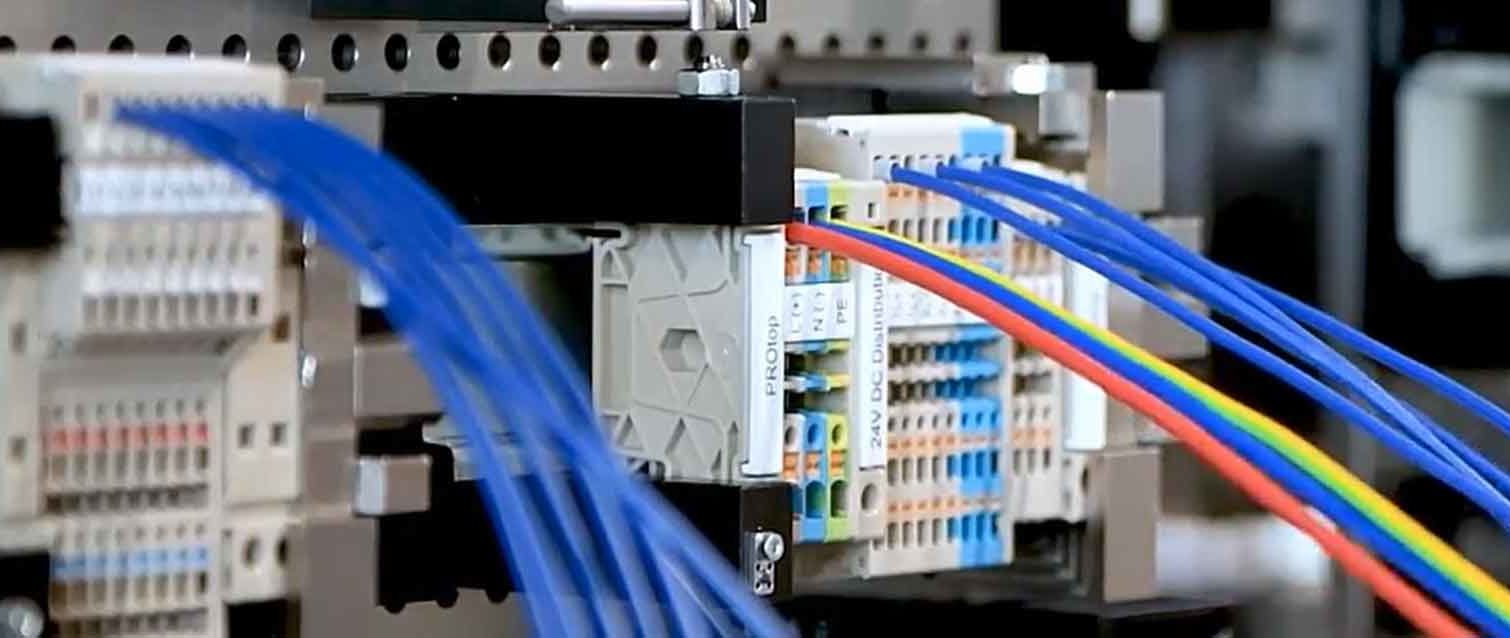

E3.series is characterized by its comprehensive data model. This high-quality data can also be used for production beyond the development process. In this webinar we shall look at how stages of the control cabinet or smart cabinet building process can be enhanced by specific E3.series tools and add-ons.

There is an extensive portfolio of interfaces and tools available in E3.series that can be used to supply automation tools commonly on the market with the necessary data. Shorter change cycles with higher product complexity, increasing variant diversity and shorter lead times can only be solved efficiently with data consistency.

What to expect

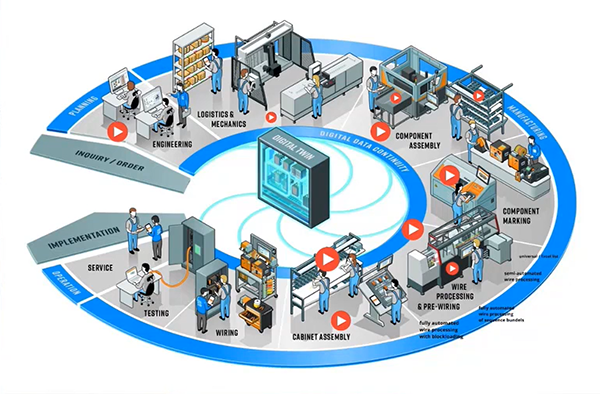

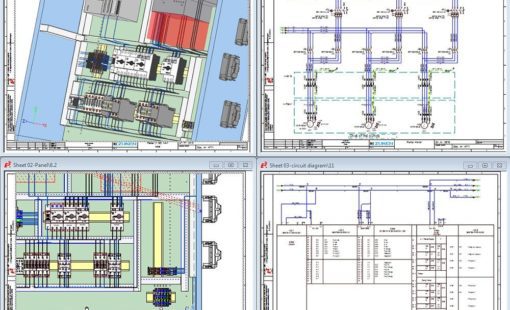

- How to create a Digital Twin with E3.panel and export data for machinery / manufacturing

- Creation for housing and mounting plate processing – E3.CutOut

- Exporting mounting rail data from E3.series to the Weidmueller configurator and rail assembler

- Digitally guided assembly of modular components – E3.AssemblingCockpit

- Fully automated production of pre-assembled wire bundles E3.ExportToKomax

- Digitally guided wiring – E3.WiringCockpit

- Interface to the Weidmüller Configurator for fully and semi-automated assembly of terminal strips, as well as laser marking

- Assisted final panel mounting – E3.ExportToELAM

- Digitally guided commissioning check – E3.WiringChecks

- Precisely fitting and online generated circuit diagrams, especially for service – E3.ConnectivityBrowser

Presenter

Achim Sterner

E3.series Product Manager

Zuken E3 GmbH, Ulm, Germany

Related Content

- Solutions

Weidmüller, Komax, Zuken, nVent Hoffman / Steinhauer and Armbruster Engineering launch the SMART CABINET BUILDING initiative

- Products

E3.panel allows engineers to layout components inside panel enclosures in both 3D and 2D. Intelligent automatic snapping points allow parts to be easily placed in their correct location.