Through the standardization of design data and libraries we have created the foundation for the systematic reuse of existing designs.

Paul BurgerGroup Leader PCB Design Research + Development, Endress+Hauser

Modular product architectures are considered a breakthrough approach for controlling product and manufacturing complexity in today’s world of fast-paced technological innovation.

To use modular product architectures successfully, the engineering information infrastructure needs to be solid. This is because interdependencies between modules must be maintained to support efficient engineering change and configuration management processes.

Powerful design data and configuration management functionality directly integrated into the familiar user interface of our authoring tool environements CR-8000 and E3.series provide a solid basis for the adoption of modular product architectures.

With our DS-2 technology, we provide powerful libraries and material data management capabilities for native design management, and propagation of changes to variants and related designs.

Built on industry standard object-oriented architecture, our solutions are fully equipped to integrate into existing PDM/PLM and ERP environments, providing a true electromechanical data model with full visibility of electrical and electronic designs down to component level.

Our satisfied customers

Recent Modular Design Blog Posts

A modular product approach is an established way of improving the calculating and realizing the value of investment goods. Yet modular product initiatives often fail to live up to expectations because of poor coordination between engineering disciplines. To deliver on the promise of a modular product architecture strategy, companies need to create a number of prerequisites in organization, process, and infrastructure.

A modular electrical design comes with its own set of unique challenges. However, the basic principles of the solution are the same. With this in mind, let’s think modular when it comes to a modular design.

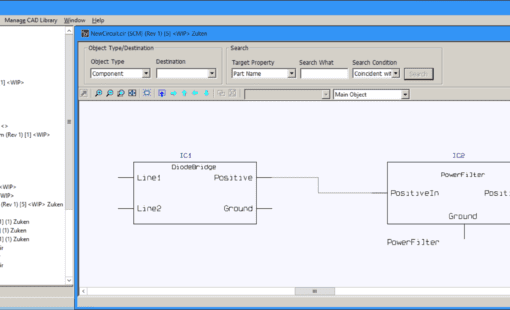

Modular circuit design allows engineers to create a set of electronics building blocks that can be reused and shared between products. The Circuit Block Manager facilitates reuse management and change control of a library of circuit blocks in a convenient and organized manner. This brief video shows how simple it is to use a hierarchical schematic containing circuit blocks as the basis for a modular circuit block library within DS-CR.

It sounds like a paradox: electronics manufacturers can increase variation within a product line while using fewer electronic components. Reuse keeps product costs low, increases product flexibility and customization. Far from paradoxical, the approach is quite doable today through a process called modular board design coupled with predictive analysis numbers returned by the Internet of Things.

Related resources

Check our latest webinars, white papers and more

To deliver on the promise of a modular product architecture strategy, companies need to create a number of prerequisites in organization, process and infrastructure.

Related products and solutions

DS-CR supports the specific demands of PCB design data management. It combines multi-site library, design data, and configuration management capabilities into a unified engineering environment.

Tell us more about your challenge