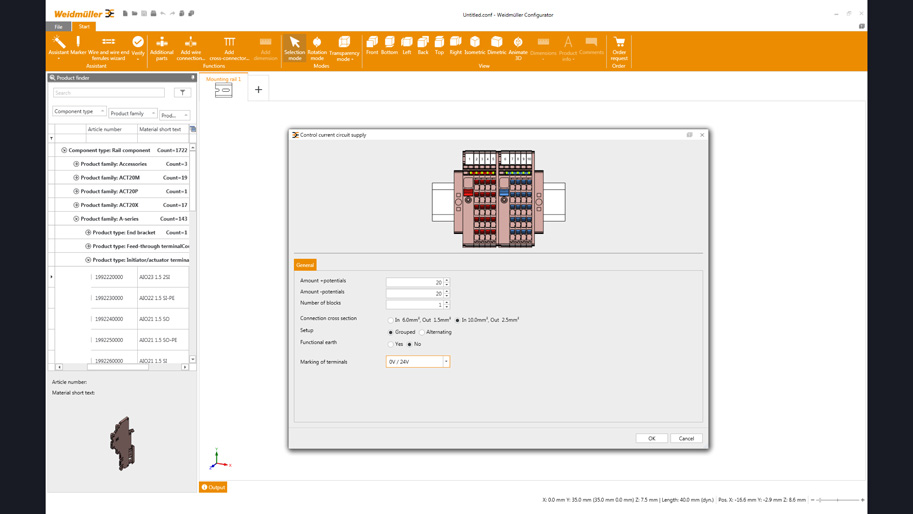

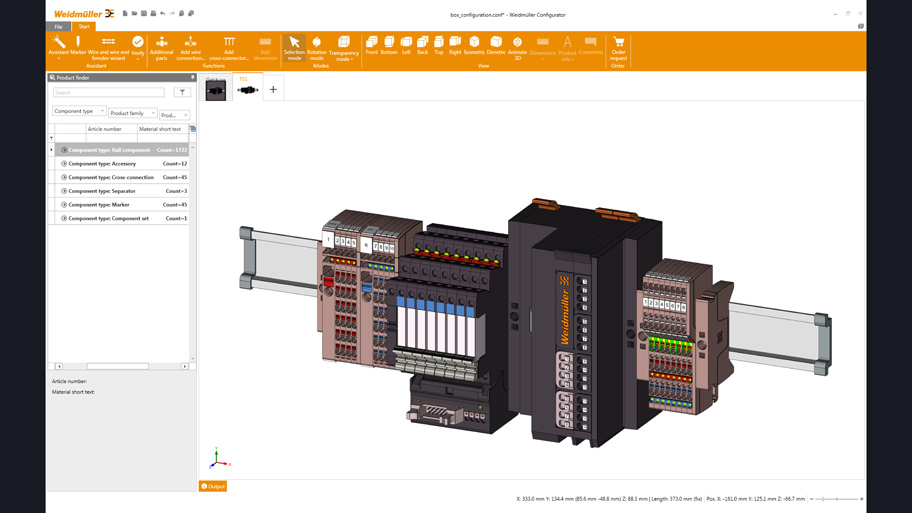

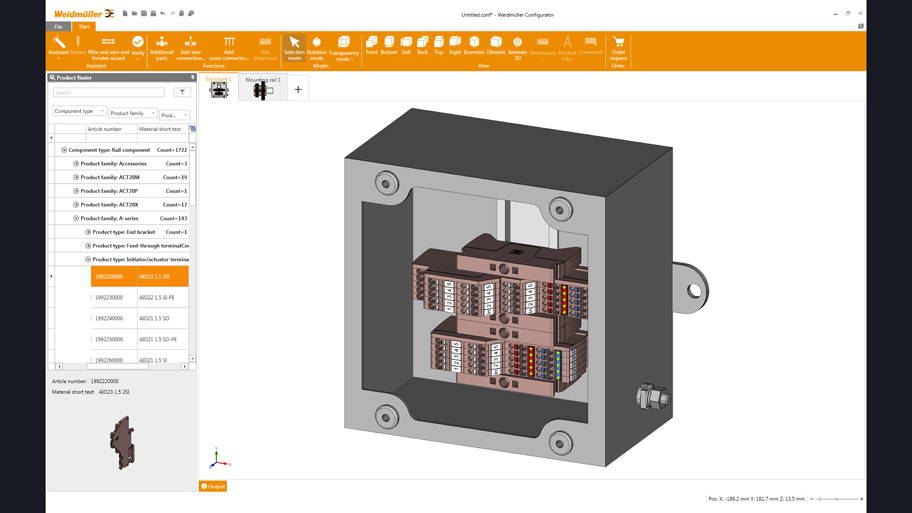

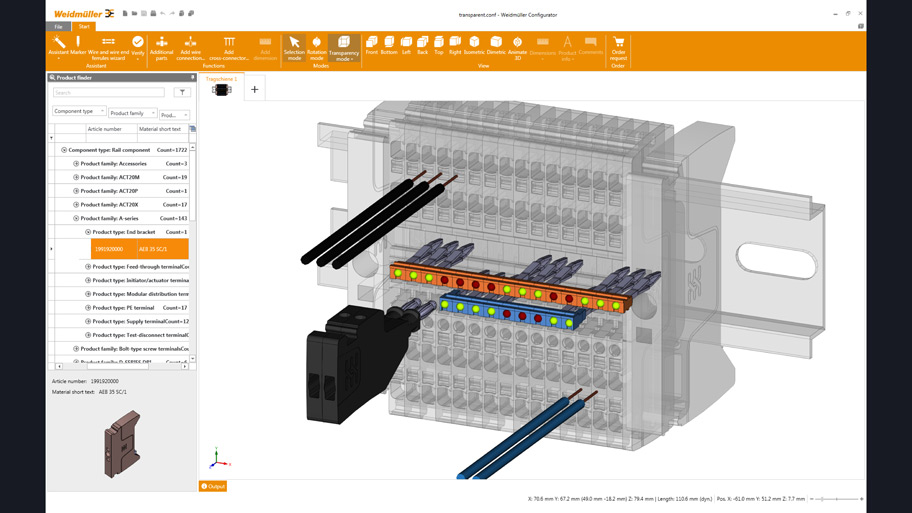

“This impressive productivity increase was achieved because the Weidmüller Configurator provides automatic filter functionality that guides the customer through a choice of more than 5,000 Weidmüller products. Erroneous configurations are automatically identified and corrected. This combines to offer improved planning and enormous time savings.” After the components have been selected, the order process can be initiated directly from within the configuration tool. The user can request quotes directly from the configuration tool: Products can be delivered both as discrete components or as pre-assembled rails, ready to be fitted into the cabinet.

At Hannover Fair 2016 Weidmüller unveiled the Weidmüller Configurator (WMC) alongside the latest addition to its portfolio – the Klippon Connect® series of terminal blocks. The new configurator was developed in a three-year collaboration with Zuken.

According to the company, this software solution streamlines the process of selecting, planning and ordering terminal rail components enhancing the efficiency in the engineering process by up to 75%.

Results

The result of the joint efforts of Weidmüller and Zuken experts is a tool in which particular emphasis was placed on the separation of data and user interface. “In this way, the content can be updated at any time in a simple library update. The possibility of running library updates without any programming effort is invaluable in a fast-paced industry such as industrial automation.”

“Through our joint support of eCl@ss Advanced, a standardized exchange format for product data, we had the opportunity to discuss requirements and implementation concepts for our future configuration tools with Zuken experts. In addition to their comprehensive experience in the development of electrical CAD tools, Zuken also impressed us with their expertise in the area of Agile project management.”

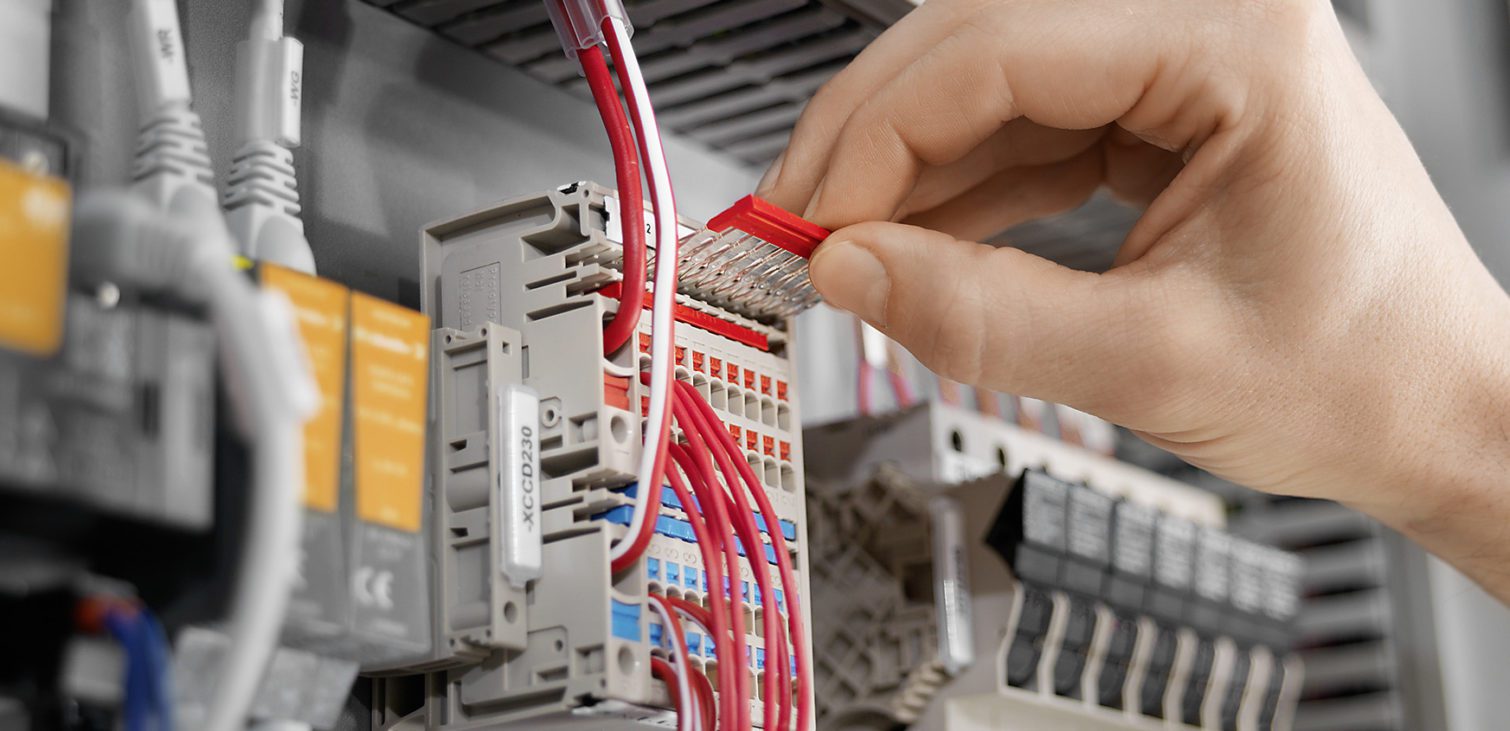

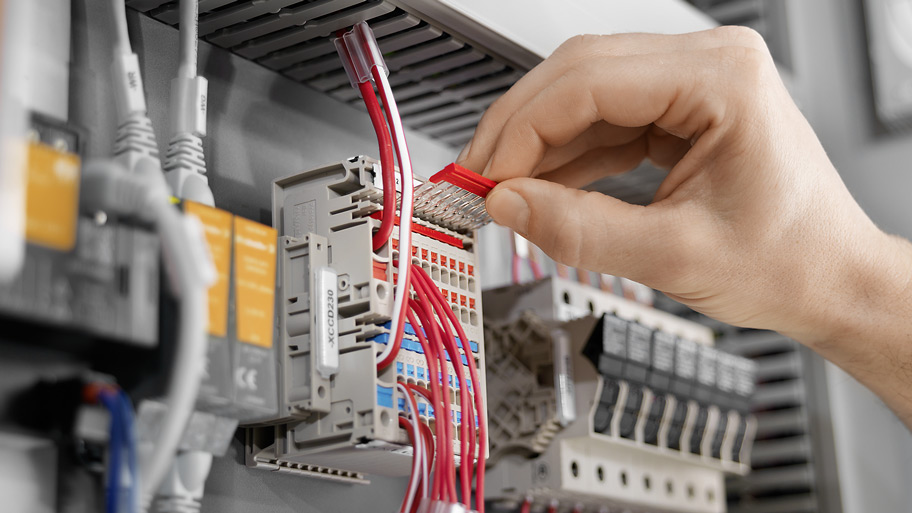

When used with an ECAD system all electrical components are handed over to the configurator where accessory parts can be added, manufacturing documentation can be compiled, and the complete assembly is submitted for logical verification. After completion, the bill-of-materials is handed back to the ECAD system for further processing.

A satisfied customer

Related products

Discover more about the products that helped Weidmüller