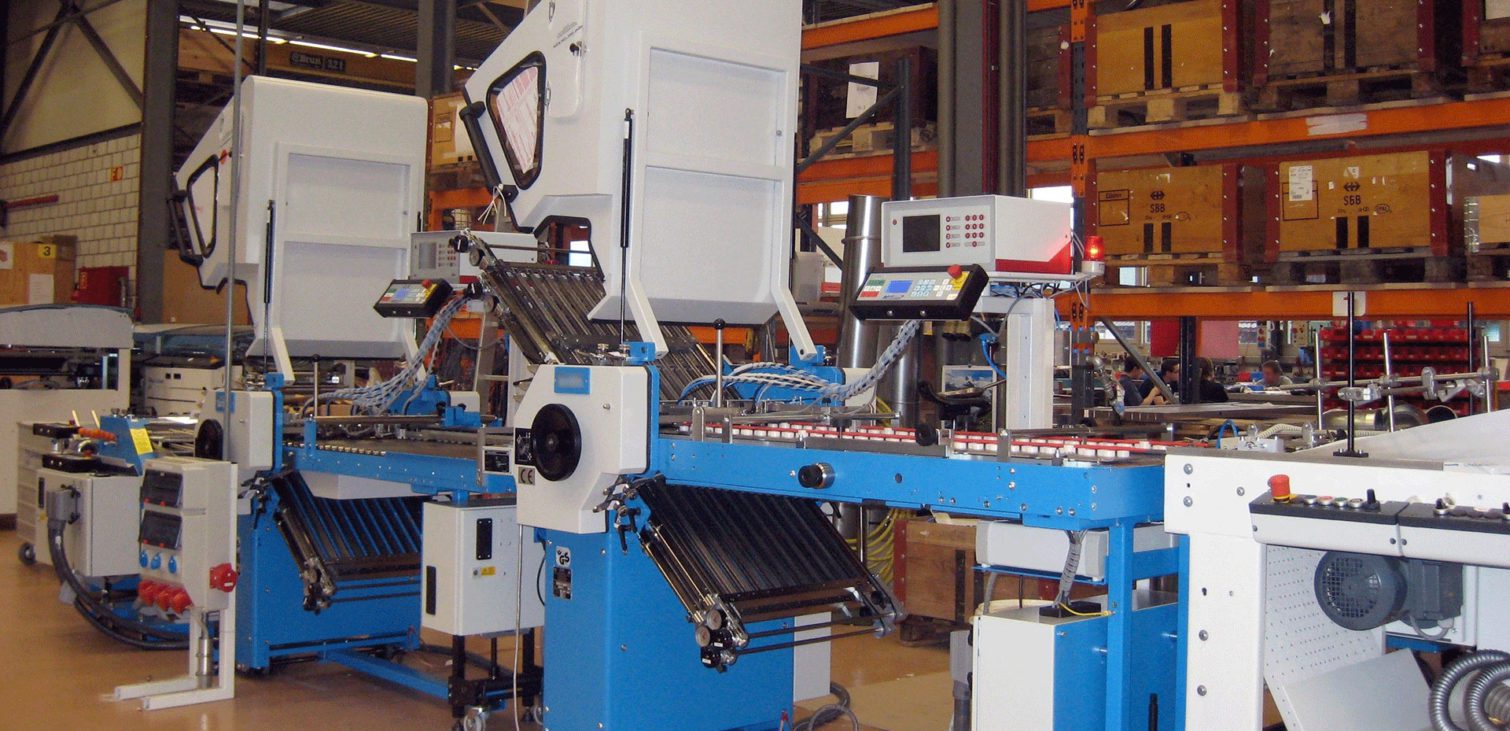

Machinery and automation are among the most important innovation drivers in the global economy – and the most competitive – with every company pushing delivery times and squeezing margins. Major challenges are created by a shift towards electronics and software, away from mechanical engineering, and a need to ensure flexibility and profitability through the adoption of modular product architectures.