ONTEC faced a difficult challenge: develop a multimedia broadcasting product while complying with a customer’s electromagnetic interference requirements, all within a tight development schedule. ONTEC used Zuken’s CR-8000 with Keysight’s ADS (including SiPro) to meet the requirements of the challenge

One of ONTEC’s new development efforts focused on designing a multimedia video broadcasting product called Multi File Player KAMELEON (MFP-330). The KAMELEON accepts a wide variety of media inputs (HDMI, SD Cards, and USB) for broadcasting.ONTEC’s customer had stringent electromagnetics requirements for low noise and interference and required delivery on a tight schedule. ONTEC took on the challenge to develop this high density, complex design that included a countermeasure circuit in a shorter than average timeframe.

To fulfill the customer’s requirements, ONTEC decided to follow a ‘right the first time’ design process. The concept was to use simulation progressively and continuously throughout development to minimize backtracking and re-spins. The design process involved:

- Conducting fast and simple power integrity simulations during schematic and layout phases of board design.

- Running detailed, time-intensive power integrity analyses to verify power integrity against earlier fast and simple simulations.

- Manufacturing and testing board prototypes to correlate physical results against power integrity analyses.

ONTEC discovered that Zuken and Keysight Technologies alone provided an integrated solution to meet their design needs

At a Glance

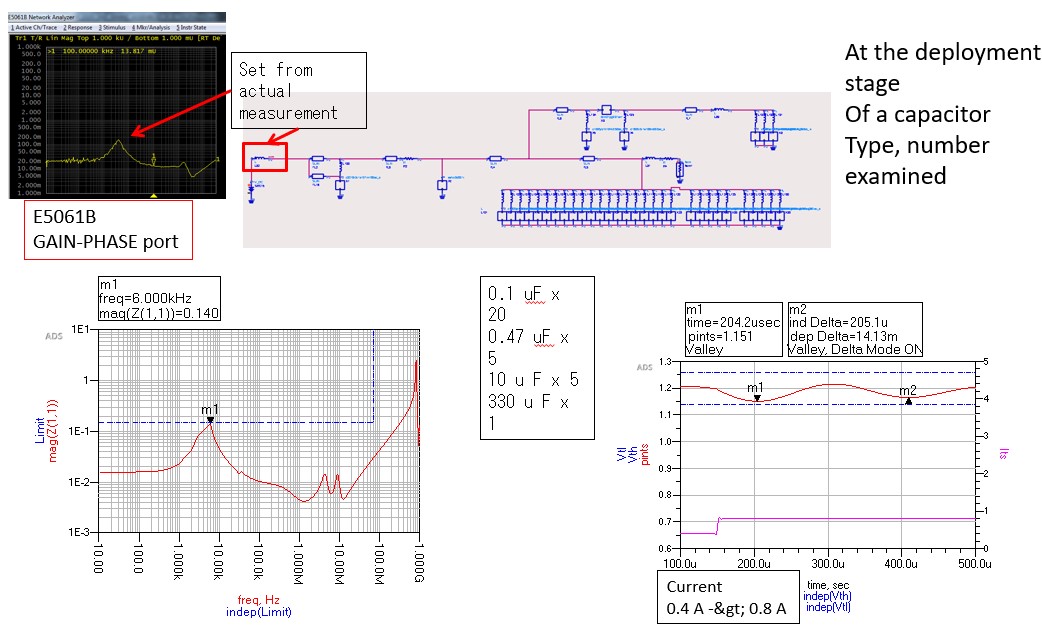

Engineers passed pre-layout designs from CR-8000 to Keysight’s ADS for fast, easy, low-fidelity simulations and used results to drive design decisions. The higher signal speed caused complicated interactions between impedance and attenuation. By iterating on via distance and size, they found the right balance to maintain power and signal integrity.

Next, ONTEC’s engineers proceeded to the post-layout phase for the circuit boards. As engineers placed components and routed the traces, they shifted those designs to Keysight’s ADS. The shift to Keysight’s ADS powered detailed, time-intensive analyses. The engineers analyzed the entire power plane, getting in-depth insight into signal and power integrity performance. The engineers also compared these detailed results with those they gained when analyzing power integrity with the pre-layout analysis. Matching results reassured engineers that they were experiencing consistent behavior as the design matured throughout the design process.

ONTEC engineers used a Keysight Network Analyzer to measure power and signal integrity during tests with modeling critical elements such as VRM and electrolytic capacitors. Pass and fail tests were critical. The engineers also compared physically measured performance against the detailed simulations conducted in Keysight’s tool. Results were remarkably similar. Again, ONTEC’s engineers were reassured about the power integrity of the KAMELEON’s boards.

ONTEC’s design process can be simply summarized as follows: start with the simulation and come up with the design standards. During the PCB layout design, the engineers repeatedly analyze the various aspects in signal and power integrity with Zuken and Keysight tools. Finally, they measure the performance with the actual prototype boards and compare the simulation with the actual measurement results. Engineers identify performance gaps and improve the design methodology, which result in an overall reduction in the number of the prototype boards that are physically built. The image below depicts the overlay of the simulation result and the actual measurement with the board, demonstrating the accuracy of simulation results