In the final installment of this blog series, you can learn how to use build-up layers and premium FPGAs to deal with the signal integrity challenges arising from high-speed signals in a 3D design capture world.

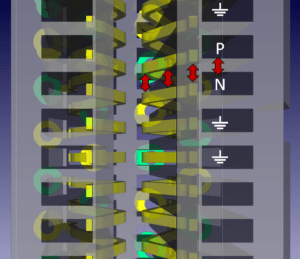

Placing return vias

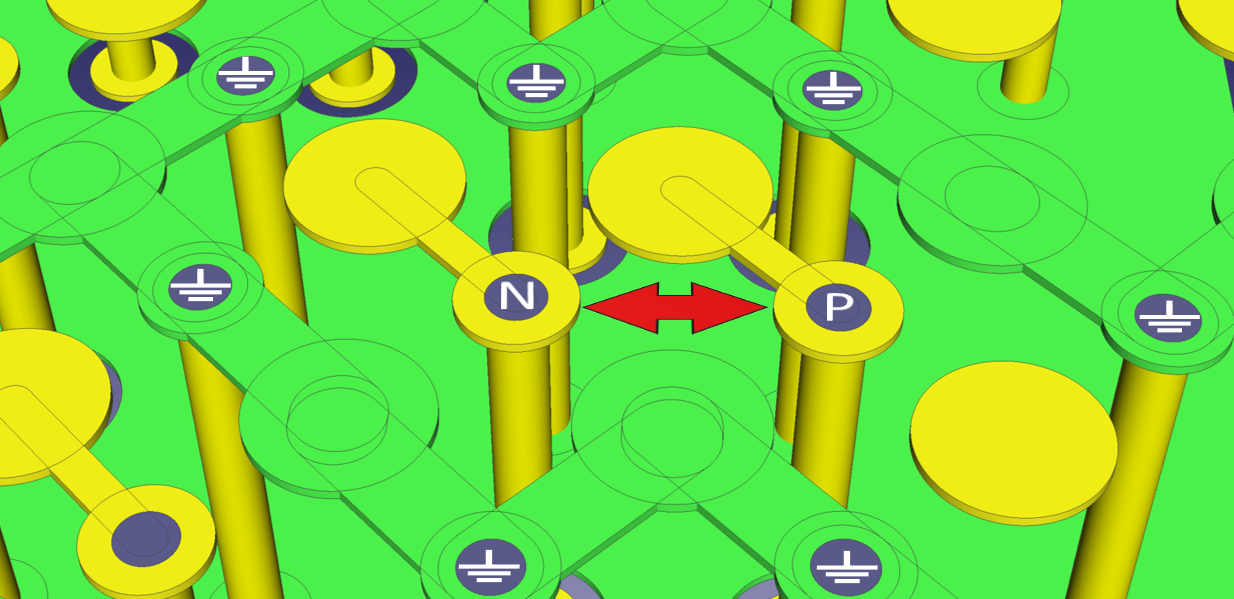

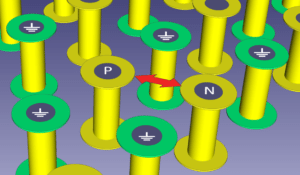

This one is a through-pin component. The two sides of the differential pair (I’ve marked them P and N), are close to ground pins. There’s some differential coupling between the P and N pins and the ground pins create returns in the Z dimension, just like ground planes do for traces.

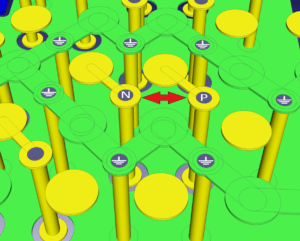

The connector body works in a similar way. Here’s a small area of the connector, mounted on its footprint. Inside the body, the differential pair has ground metal each side.

Or do you?

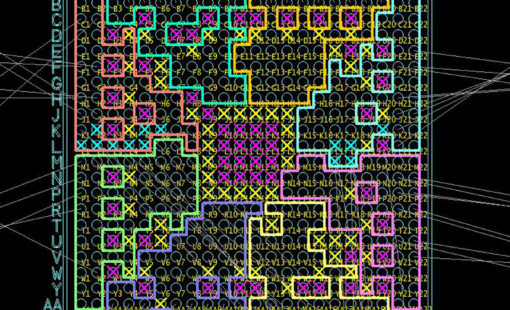

Let’s look at the BGA itself. In this case, its balls are on a 1mm grid, fanned out to vias at even spacing. I’ve added markers on the vias to show the differential pair (N and P) and surrounding ground vias. These signals are on a special high-speed transceiver bank on the FPGA. If you need another layer change, then one way to decide on spacing is just to copy this pattern.

Alternatives to return vias

- Build-up vias are also much smaller than conventionally-drilled vias and their correspondingly smaller parasitic resistance, capacitance and inductance yield better performance even on slower signals.

- Blind and buried vias add process steps and expense.

- Backdrilling is mainly suited to larger via geometries, so its use is limited, but it’s effective for signals that are a little less critical than PCI Express, such as some SDRAM buses.

Conclusion

Premium components like the FPGA mentioned here include features to help signals fly true. Some of the latest BGA footprints are so fine-pitched that many signals connect through via-in-pad to inner layers only with no room for tracks between pads.

Now that EDA environments work in three dimensions and with high levels of detail, it’s much easier to visualize where signals are going and what will help or hinder them.

Also See:

- Products

Der Graphical Pin Manager von CR-8000 bietet eine effektive FPGA/PCB Co-Design-Umgebung für die neuesten Bauelemente von Anbietern wie Xilinx, Intel, Lattice und Microsemi.

- Products

CR-8000 umfasst eine Suite von Anwendungen, die den gesamten Lebenszyklus des PCB Engineerings abdecken.