WESTFORD, MA, USA – Harness Builder 2021 for E3.series introduces enhancements to augment, automate, and improve wire harness design modularization and manufacturing documentation. Harness Builder for E3.series is a cutting-edge solution to efficiently take the wire harness manufacturing process from start to finish. It enables the designer to use intelligent designs to simplify the quoting process, automate the harness documentation process, and drive next-generation manufacturing processes. The combination of a reusable smart parts database, 1:1 scale formboard drawings, and outputs to drive testing and wire-processing machines improves the design process while reducing manufacturing costs.

“Improving the communication between design and manufacturing is a foundational element of a good design process. Adding the ability to create automated manufacturing documentation and instructions directly from engineering data to match customer requirements is a game-changer for the wire harness design process.”, comments Paul Harvell, Product Director of E3.series.

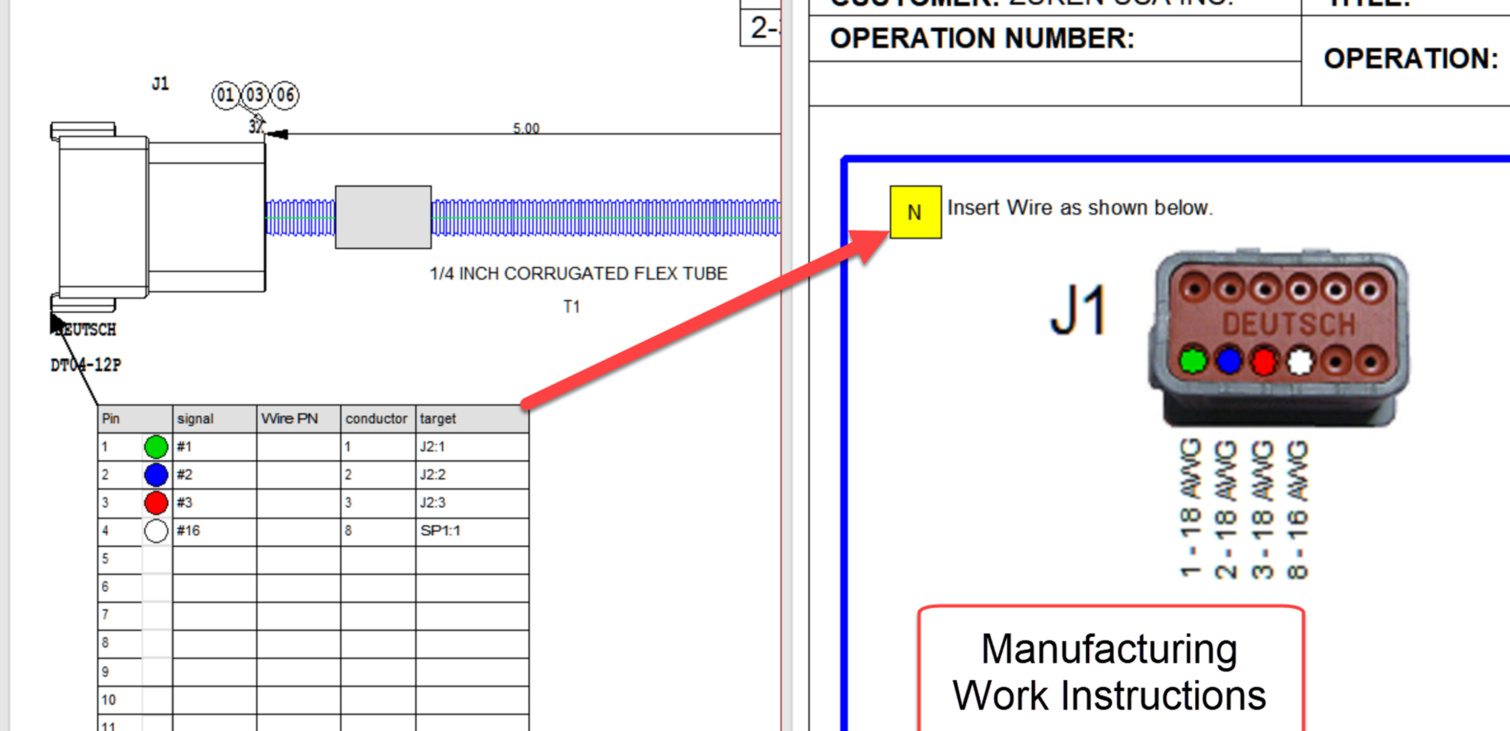

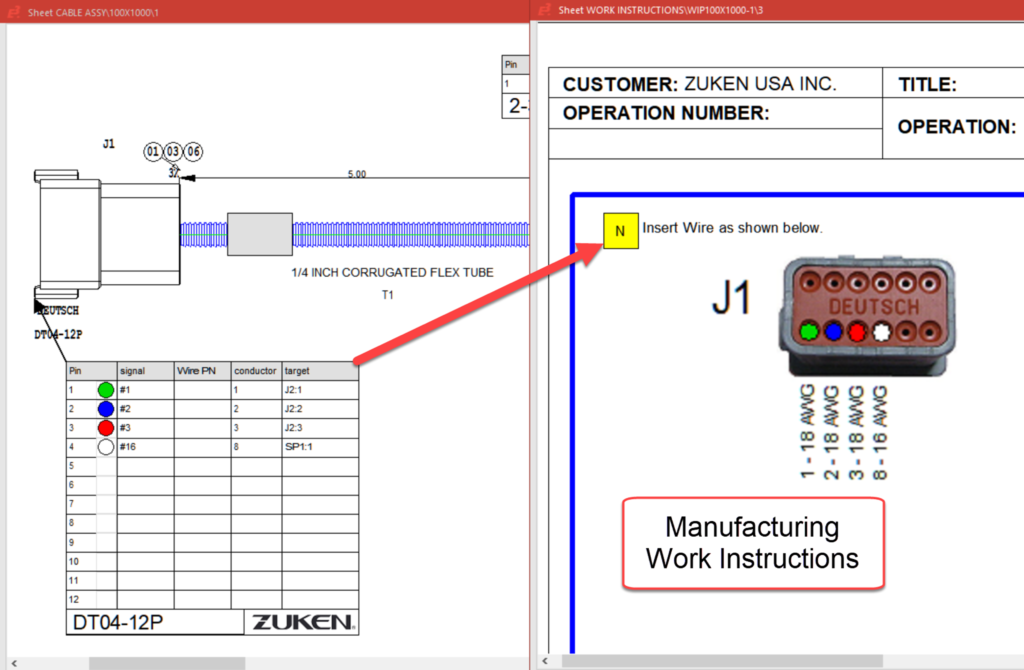

Work Instructions Assistant

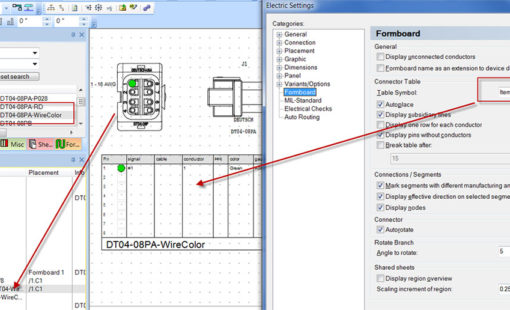

Manufacturing work instructions are commonly used documents to communicate the steps to perform assembly and manufacturing tasks. Wire harness work instructions are a customized mix of standards, best practices, testing routines, and assembly procedures. Creating and managing work instructions is typically a time-consuming, manual, and error-prone process. Harness Builder 2021 for E3.series introduces an assistant to augment the work instruction creation process and automate time-consuming tasks. The work instruction assistant is designed to be effective for all teams and supports a variety of operations with the help of customizable templates and custom automation options.

Manufacturing work instructions are driven by the engineering data within an E3.series project to ensure consistency across design and manufacturing. The work instruction templates stored in the design library ensure consistency across projects. At the same time, the ability to customize images and templates simplifies the setup process. The versatile auto-actions feature creates customizable triggers to run preexisting or custom automation routines. For instance, the auto action to ‘Generate the Wire Table’ creates the wire table on a specified sheet configured in the template. The work instruction package is designed as a separate document set inside the E3.series project to release and easily publish-on-demand.

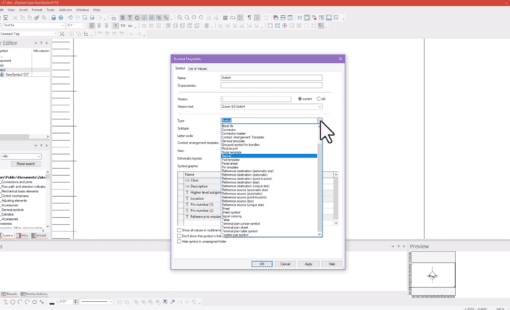

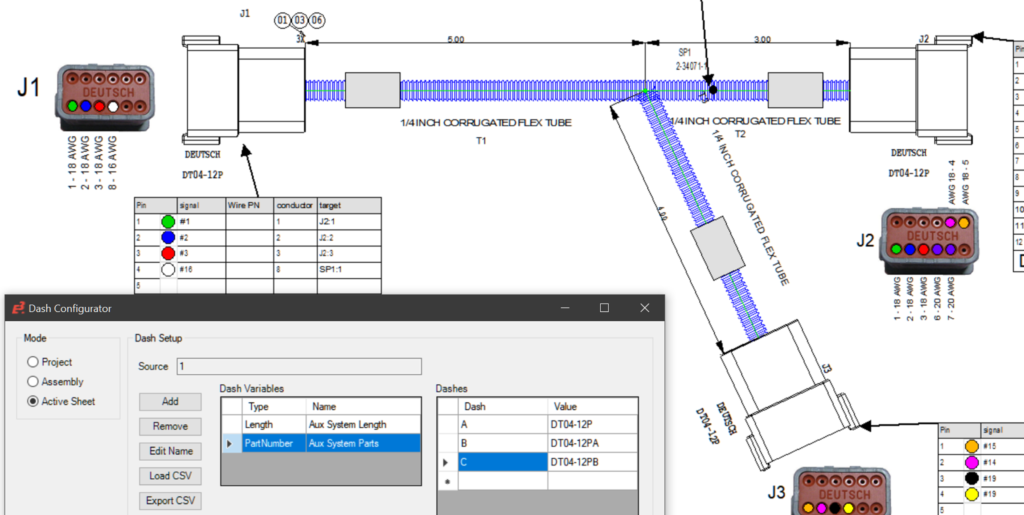

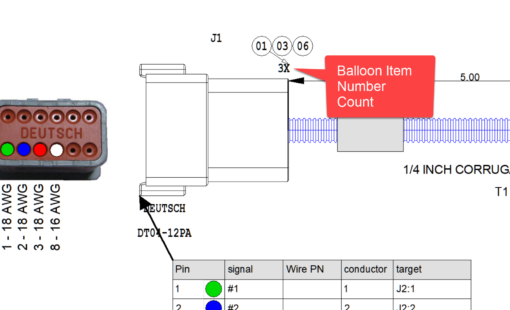

Dash Numbers

Harness Builder 2021 for E3.series introduces Dash Number functionality to improve modular design management of a harness. It is now possible to capture multiple variations of a harness derived from an original design. For example, the application derives the bill of materials for all defined permutations of a wire harness from a single design. Harness design teams save time by eliminating the repetitive task of drawing multiple variations of the wire harness to represent minor changes.

Dash numbers are configured as variables to manage parts numbers and cable segments on a formboard. For instance, connectors and cable protection part numbers may vary based on the requirement for the harness to be in a wet area, or the length may vary based on the model of the device. The configurations can be stored in a CSV file to be managed and loaded into projects, as required.

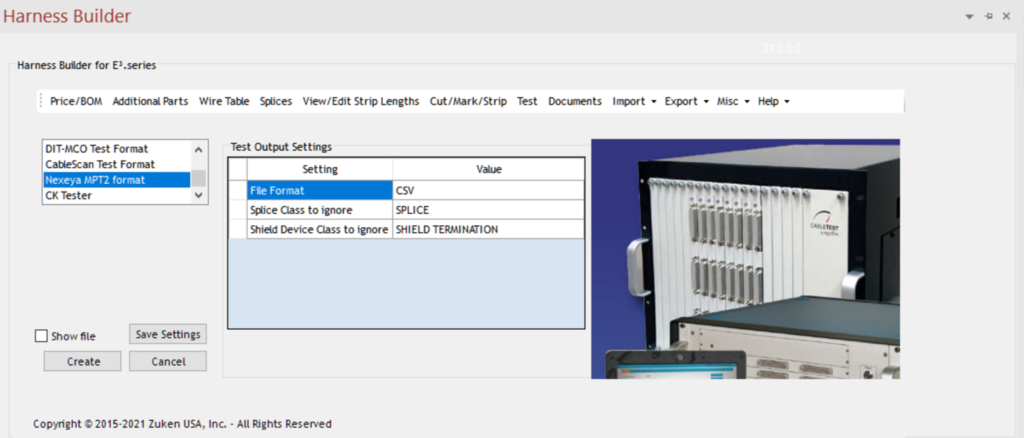

New Testing Machine Outputs

Harness Builder 2021 for E3.series expands the support for 3rd party automated wire harness testing machines. It is now possible to use the wire harness design data to drive test platforms like:

- CKT Technologies

- Nexeya MPT2 Tester

Additionally, new enhancements to DIT-MCO and Cirris test machine outputs provide more opportunities for users to automate the harness testing process.

Harness Builder 2021 for E3.series enhancements cover all areas of the wire harness manufacturing process. Additional new features and functional updates include:

- New ‘Cut to Length Only’ options for Schleuniger cayman wire processing machines

- Multiple reporting enhancements for Wire tables On-sheet and in Excel

- Plugin and options for ProjectionWorks augmented reality assembly systems

- UI improvements and performance enhancements

Harness Builder 2021 for E3.series is available now in North America. For more information, visit our website.

Related Products & Resources

- Products

- Products

- Products

E3.series is a Windows-based, scalable, easy-to-learn system for the design of wiring and control systems, hydraulics and pneumatics. The out-of-the-box solution includes schematic (for circuit and fluid diagrams), cable (for advanced electrical and fluid design), panel (for cabinet and panel layout), and formboard (for 1:1 wiring harness manufacturing drawings). Integrated with MCAD, E3.series is a complete design engineering solution from concept through physical realization and manufacturing output.