Adressing Challenges Together

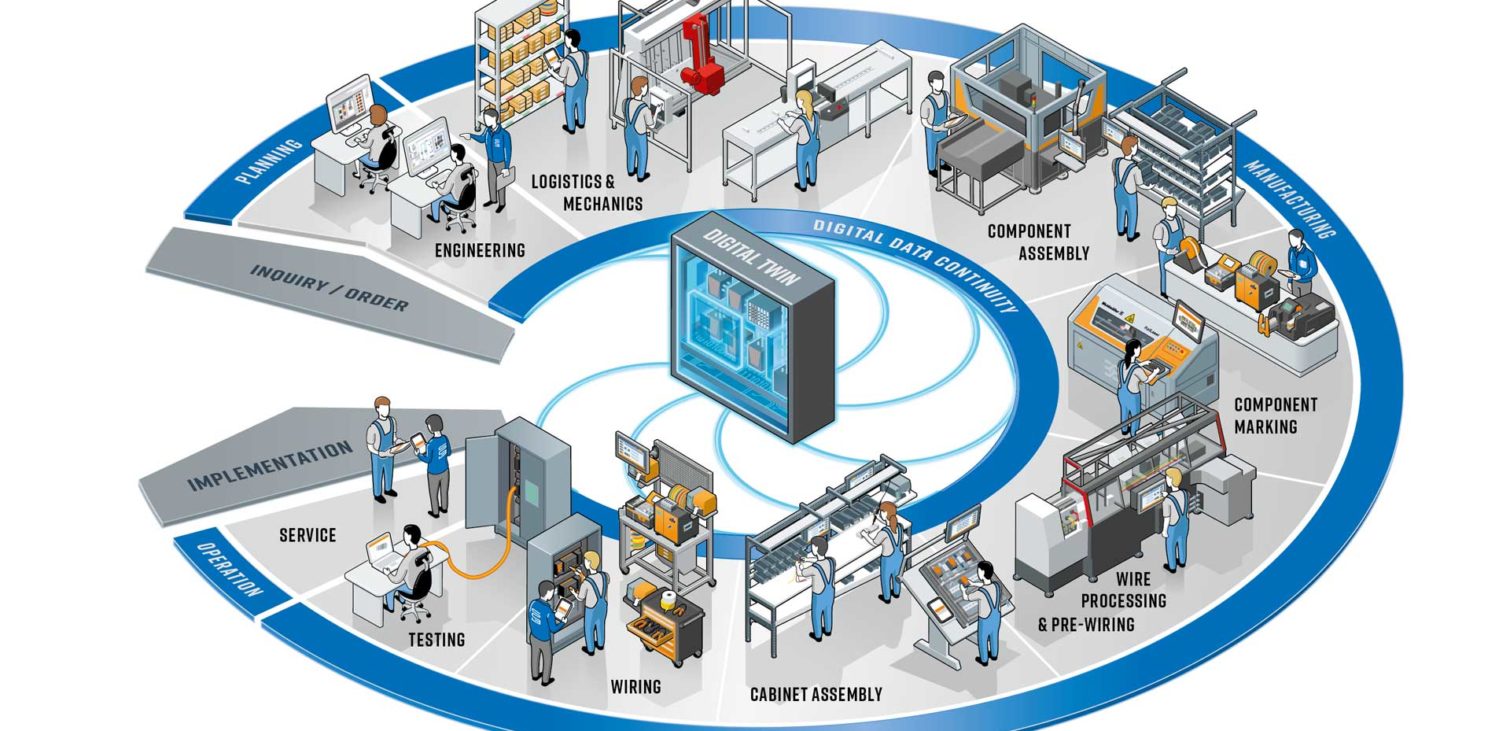

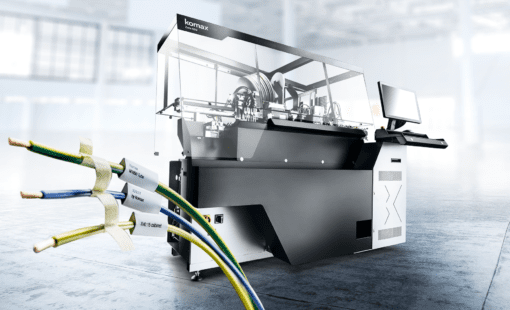

Opening new opportunities through digitalization in control cabinet manufacturing with customized, integrated solutions: To achieve this goal, the companies Weidmüller, Komax, Zuken, nVent Hoffman / Steinhauer and Armbruster Engineering have founded the SMART CABINET BUILDING initiative. These companies – technology leaders in different areas of electrical cabinet building – are now pooling their expertise and know-how

Weidmüller, Komax, Zuken, nVent Hoffman / Steinhauer and Armbruster Engineering have launched the SMART CABINET BUILDING initiative to provide new solutions in electrical cabinet manufacturing. The partners are joining forces to leverage the potential of digitalization in electrical cabinet manufacturing with customized, end-to-end solutions.

-

Leveraging Digitalisation

-

The control cabinet industry is facing many different challenges: a wide variety of technical options, rapidly changing customer requirements, cost and price pressure, and tight delivery deadlines. Addressing these challenges requires the utilization of automation and digitalization in a perfect combination of product, process, and production resources.

-

Technology and Expertise

-

Digitalization offers many options for the optimization of production processes. However, overall productivity increases can only be achieved if the individual aspects of the value-added process are taken into consideration. Our goal is to provide comprehensive solutions for today's and future challenges in control cabinet manufacturing by networking technology and expertise across all process stages.

-

Smart Tailored Solutions

-

Currently, there is a lack of consistent, cost-effective solutions to meet the individual needs of the control cabinet industry.To enable the electrical cabinet building industry to unlock the potentials of digitalization with tailored solutions, Weidmüller, Komax, Zuken, nVent Hoffman / Steinhauer and Armbruster Engineering have joined forces to launch the SMART CABINET BUILDING initiative

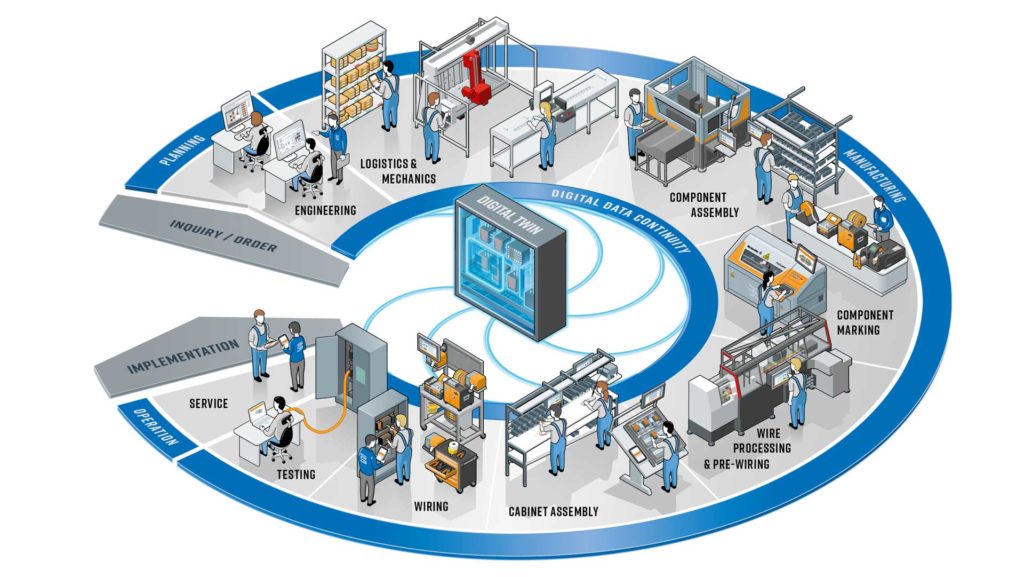

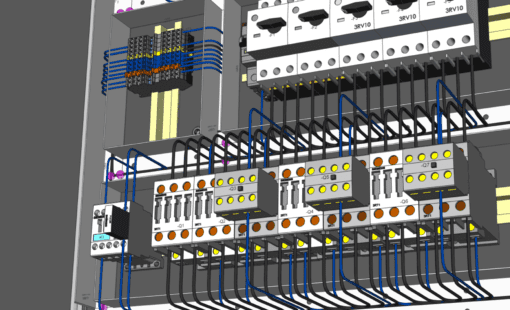

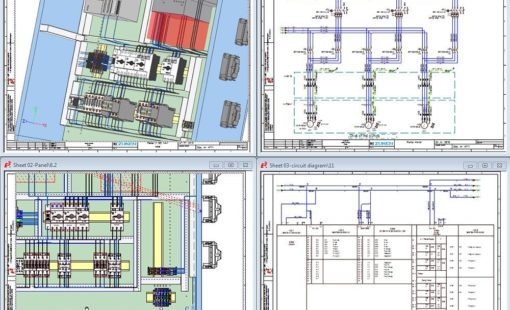

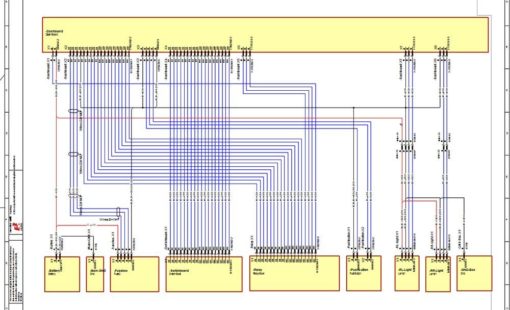

The automation of control cabinet manufacturing and assembly has a significant potential for cost-efficient on-shore production. The digital twin created in E3.series provides an excellent foundation for all downstream processes.

Introduction to Smart Cabinet Building initiative

Take the Smart Cabinet Building Tour

Watch seminars from KOMAX, with contributions from all the Smart Cabinet Building partners

On-Demand Webinars

Watch Now

- Webinar

In cabinet building, the use of modern machining centers such as the nVent Hoffman ModCenter or NC-Cut can optimize processes and save up to 80% in running costs, while also counteracting the shortage of skilled workers. Our partner nVent Hoffman from the Smart Cabinet Building Initiative will show you concrete examples.

- Webinar

In this Smart Cabinet Building webinar, we will present you a selection of new functions of the E3.series 2022 release. This session concerns enhancements in E3.panel, as well as the tools for manufacturing automation, in particular E3.CutOut, E3.ExportToKomax and E3.WiringCockpit.

- Webinar

In this Smart Cabinet Building webinar, our partner Armbruster and Weidmüller will show you how to save up to 60% in time and efficiency per cabinet control building process step.

- Webinar

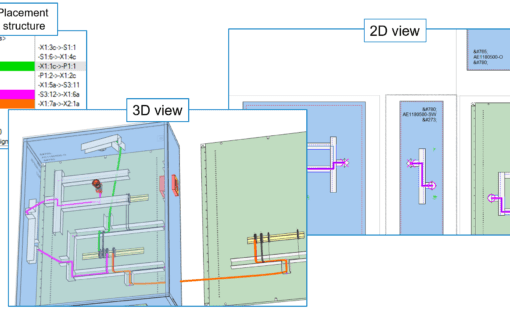

In this Smart Cabinet Building webinar, Cornel Durrer, Manager Market Segment Industrial at Komax AG will show you the advantages of the new Zeta model, and how to use it to optimize your processes and save effort and costs in production

- Webinar

In this Smart Cabinet Building webinar, Frank Polley, Head of the Connectivity Consulting team at Weidmüller will go through proven methods for optimizing your control cabinet and show you how you can gain up to 20% space by sorting, dimensioning, optimization and decentralization.

- Webinar

In this Smart Cabinet Building webinar, you will learn how to address the challenge of the shortage of qualified workers in control cabinet building by optimising seqences and tools for tomorrow's production

Additional Resources

- Press Release

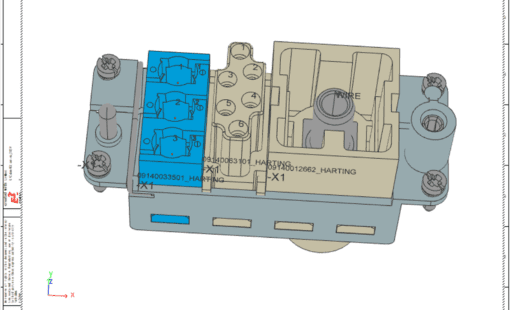

E3.series 2022 optimizes manufacturing with advanced 3D cabinet and wiring visualization, expands support for prefabricated cables to simplify modular design reuse, simplifies power distribution layout with improved busbar handling, and enables design modularization with intelligent design reuse options with subcircuits.

- Press Release

E3.series 2021 from Zuken delivers enhancements for connector handling, 3D control cabinet design and ECAD/MCAD collaboration.

- Press Release

Leveraging the opportunities of digitalization in control cabinet manufacturing together with customized, integrated solutions: To achieve this objective, Weidmüller, Komax, Zuken and Armbruster Engineering founded the "Smart Cabinet Building" initiative in April 2020.

- Blog

Reducing costs, increasing productivity and ensuring quality – this is the wisdom that every management consultant in the manufacturing industry has in their briefcase today. In fact, over the past two decades, the industry has allocated significant budgets to achieve these goals. At the same time, companies often overlook money that is literally lying on the shop floor in the form of obsolete paper-based transitions to manufacturing – in particular in the areas of electrical engineering and assembly.

Related Products

- Products

E3.panel allows engineers to layout components inside panel enclosures in both 3D and 2D. Intelligent automatic snapping points allow parts to be easily placed in their correct location. Clashes can be prevented with keep-out and height restrictions.

- Products

E3.cable extends the functionality of E3.schematic enabling individual conductors to be combined together in the design to form cables and harnesses.