Cable planning and switch cabinet assembly

As this discussion continues in board rooms and shop floors, the most common questions that come up are these . . .

- Can an electrical design to the manufacturing process be completely digital?

- Is it feasible and cost-effective to drive the time-consuming parts of the process towards a digital flow of information?

The short answer is YES! The Zuken and Komax collaboration to expedite design to manufacturing is simply amazing. The process is opening new avenues by automating the underlying challenges without losing control over the nuances.

Digitization enables reliable processes

The latest generation tools rely on a library that stores the electrical characteristics of components in a standardized form. This enables the use of design rule checks during the design. In addition, the library establishes a reliable source for parameters and data needed for the digitization of the manufacturing process. Parts and connection lists compiled automatically reduce the laborious and error-prone process of manual list compilation.

With the help of fast, accurate, and reliable data, commissioning cable harness suppliers drastically improves. A simple digital representation on the shop floor helps improve the communication of engineering information to the manufacturing floor. A great example is the use of a tablet, or even an augmented reality device to guide the workers through the wiring, checking, and documentation procedures before startup.

The following video, produced in collaboration with our partner, Komax, a pioneer and market leader in the field of automated wire processing, shows an example of an end-to-end digital production and assembly process starting with E3.series design software from Zuken and ending with a Komax Zeta 630. The result: efficient and robust management of customer-specific variants and a significant reduction in time and effort for cabinet production and cabinet assembly.

Related Content

- Solutions

Weidmüller, Komax, Zuken, nVent Hoffman / Steinhauer and Armbruster Engineering launch the SMART CABINET BUILDING initiative

- Products

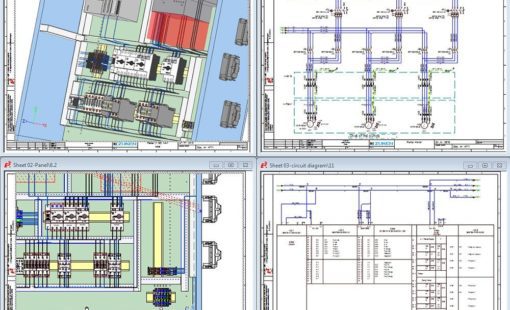

E3.panel allows engineers to layout components inside panel enclosures in both 3D and 2D. Intelligent automatic snapping points allow parts to be easily placed in their correct location.