The world of business operations is changing rapidly, and the digital twin is a key player in this transformation. Essentially, digital twins are virtual replicas of physical assets, systems, or processes that provide valuable insights and allow businesses to optimize their performance. While this concept isn’t entirely new, recent advances in IoT, cognitive services, and cloud computing have vastly improved the capabilities of digital twins. By leveraging this approach, companies can optimize production, reduce downtime, and improve operational efficiency.

Unlock benefits through the product lifecycle

Incorporating a digital twin strategy into a business can unlock benefits throughout a product’s lifecycle. Utilizing a digital twin approach, companies can test and validate new designs, processes, and systems without incurring additional expenses or risks, speeding up the time-to-market process. As products mature and become operational, digital twins help facilitate real-time performance monitoring and analysis of physical assets, enabling businesses to identify potential issues and predict failures before they happen. This results in the prevention of downtime and the boost of overall system efficiency.

However, before investing in a digital twin, it is important to have a clear idea of your business objectives. Intended business benefits can take various forms, such as increased efficiency, cost savings, improved quality, better decision-making, enhanced customer experience, or new revenue streams. Without a realistic goal, the digital twin remains a shiny new but essentially useless toy.

It’s crucial to involve stakeholders from different departments and levels of the organization in this discussion to ensure that the strategy is aligned with the different needs of the business and the people who will be using it. With everyone on the same page, the risk of error is significantly lower.

The digital twin for control cabinet building

An excellent example of a well-thought-out digital twin strategy is the Smart Cabinet Building initiative. This initiative has carefully considered every aspect of control cabinet manufacturing, from the concept to assisted and automated production.

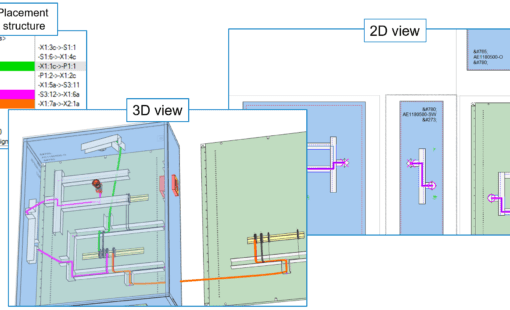

Once the model is created in the electrical design using Zuken E3.series, the digital twin can supply useful information throughout the entire product lifecycle. The mechanical processing of the panel enclosure can then be carried out on machinery like the Modcenter from nVent Hoffman Steinhauer. Solutions such as Weidmüller’s RailAssembler and RailLaser automatically assemble and label the terminal strips.

Automatic wiring and pre-wiring can be performed on wire confectioning machines such as Omega from Komax, and finally, all components can be assembled using an assisted workstation from Armbruster Engineering, which guides workers through the assembly process. By leveraging the connected solutions from Smart Cabinet Building the entire process is streamlined and automated, resulting in improved efficiency and accuracy.

While digital twin strategies currently tend to prioritize architecture development, detailed design, and production, one crucial aspect of the digital twin’s product lifecycle often gets overlooked: customer service. Zuken’s E3.ConnectivityBrowser technology enables customized circuit diagrams to be visualized in real-time as a digital connectivity model for individual users and applications.

How to successfully implement a digital twin strategy

To implement a successful digital twin strategy, businesses should follow these key steps:

- Define intended business benefits: Developing a digital twin strategy should always begin with the intended business benefits, outcomes, and impact on people, practices, and processes.

- Identify the assets, systems, or processes that can benefit from digital twins: Start by identifying the assets or systems that could benefit from digital twin technology. This could include machines, equipment, buildings, or entire production lines.

- Build the digital twin: Once the assets have been identified, it’s time to create a digital twin.

Modern CAD tools help create high-precision 3D models with comprehensive data down to component level. - Verify the model: Verifying a digital twin is essential to ensure that it accurately reflects the product requirements.

- Connect the digital twin to the physical system: The digital twin must be connected to the physical system to ensure that real-time data is collected and analyzed. This can be done using IoT sensors or other data collection tools.

- Analyze data and make improvements: Once the digital twin is in place, it’s time to analyze the data and make improvements. This involves using advanced analytics tools to identify patterns and trends, predict failures, and optimize performance.

Summary

Exploring the possibilities of a digital twin strategy can revolutionize the way businesses operate. We are contributing to the digital twin by providing software tools that enable the creation and simulation of high-precision 3D models of electrical and electronic systems, helping engineers optimize their designs and improve their performance.

The E3.series platform can be used to create a digital twin of complex electrical systems. The software allows engineers to create a detailed model of the system’s electrical components and their interconnections capable of simulating the behavior of the electrical system and analyze its performance under various conditions. From the automotive industry to transportation companies, our innovative approach is helping businesses stay ahead of the curve.

- Webinar

Today's discussions about the digital twin are mainly focused on the areas engineering and production. What is often overlooked is on-site maintenance and customer service.

- Webinar

Paperless engineering improves accuracy, traceability, and schedule. Communication gaps riddle engineering companies, and E3.series tools E3.WiringChecks and E3.WiringCockpit is here to facilitate communication between design, checking, commissioning, technicians, and all parties involved after the initial design.

- Blog

What exactly is a digital twin? It is a simulated model of an actual working product in the field...