Following the successes achieved by the Smart Cabinet Building partnership in Europe, further networking of expertise in control cabinet building is now starting in the United States. The collaboration with nVent HOFFMAN is the first step towards taking the proven concept abroad and establishing a similar initiative.

nVent is a global leader in providing industrial enclosures and advanced cooling solutions and has a comprehensive machine portfolio to automate panel building. Their Design to Manufacturing Software will now be powered by E3.series to create time and labor savings in panel design and assembly.

The software provides design automation to help electrical engineers to simplify processes, and ultimately increase overall productivity. With its easy-to-use intelligent central parts library, designers can efficiently work on a project while the software automatically ensures the data is continually up to date, making the design and planning process easy.

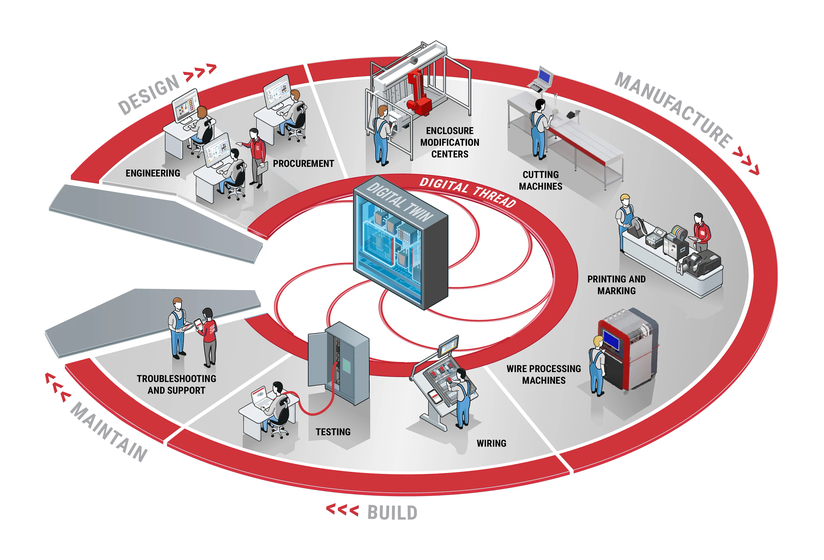

The optimized engineering process drives the creation of the digital twin with all the necessary manufacturing details. The automated panel building process with connected machines and workers, accelerates the transition to smart manufacturing. Workers can easily visualize the design and immediately access digital documentation. This automated workflow detects critical errors, significantly improves the time taken to build a panel, and maintains the overall process.

“By adding the Design to Manufacturing Software, powered by Zuken, we have significantly enhanced our value proposition by optimizing the entire panel design and fabrication process,” said Alexander van der Weide, general manager and vice president for nVent. “Companies are prudently finding ways to maximize the skills of their workforce, especially in such a competitive landscape and tight job market. This will make it easier for our customers to deliver high-quality solutions faster, with fewer resources and time-consuming steps.”

nVent and Zuken will release the collaborative software portfolio in 2023 including specially designed software packages for engineering and manufacturing processes, connecting workers to the manufacturing floor, and adding optional add-on functionalities. The software was recently showcased at the Automation Fair in Chicago.

Read the full press release here:

Read the full story

- Blog

Product Lifecycle Management (PLM) stands as a cornerstone in enhancing product development and operational efficiency, offering a comprehensive approach to navigating the complexities of modern manufacturing. Discover the strategies for effective PLM integration on our blog.

- Blog

The fuel cell is indeed a clean and sustainable energy technology, primarily due to its ability to generate electricity with minimal emissions of greenhouse gases and pollutants. However, its wider diffusion faces several challenges. Learn more on our blog.

- Blog

MLC Technologies Ltd, a fast-growing electrical engineering business specializing in delivering complex mission critical electrical and electronic solutions for data acquisition, mission control, power distribution, and navigation applications in maritime and off grid environments, has introduced Zuken’s E3.series ECAD software for the design and validation of their electronic and electrical systems and wiring harness designs.

- Blog

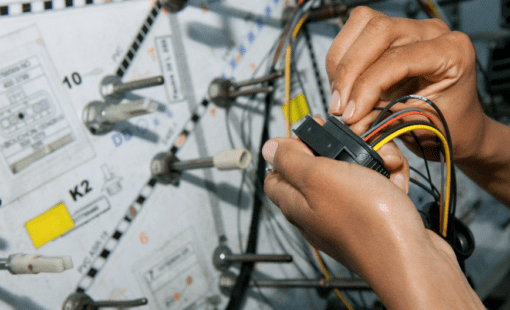

1:1 drawings of wire harnesses are frequently created by wiring harness engineers at the wiring harness supplier. But this approach has a latent risk for delays and errors.