EREMS, a French enterprise specializing in the design and realization of high-tech electronic equipment and of associated software for Space, Defense, and Aeronautics uses CR-8000 and DS-CR from Zuken for the design and lifecycle management of flight electronics, ground electronic equipment, and test benches.

Over the past 3 or 4 decades, space satellites have been delivering valuable information that helped make our lives safer and more connected by, e.g., monitoring geological conditions, weather phenomena, and even traffic. A growing number of these missions, while still under the guidance of national space agencies like NASA or ESA are today driven by private enterprises, such as Airbus in Europe or SpaceX in the US, who in turn employ a network of highly specialized suppliers to develop innovative and cost-effective solutions. This trend of reducing the cost of space missions by harnessing private entrepreneurship is typically referred to as New Space.

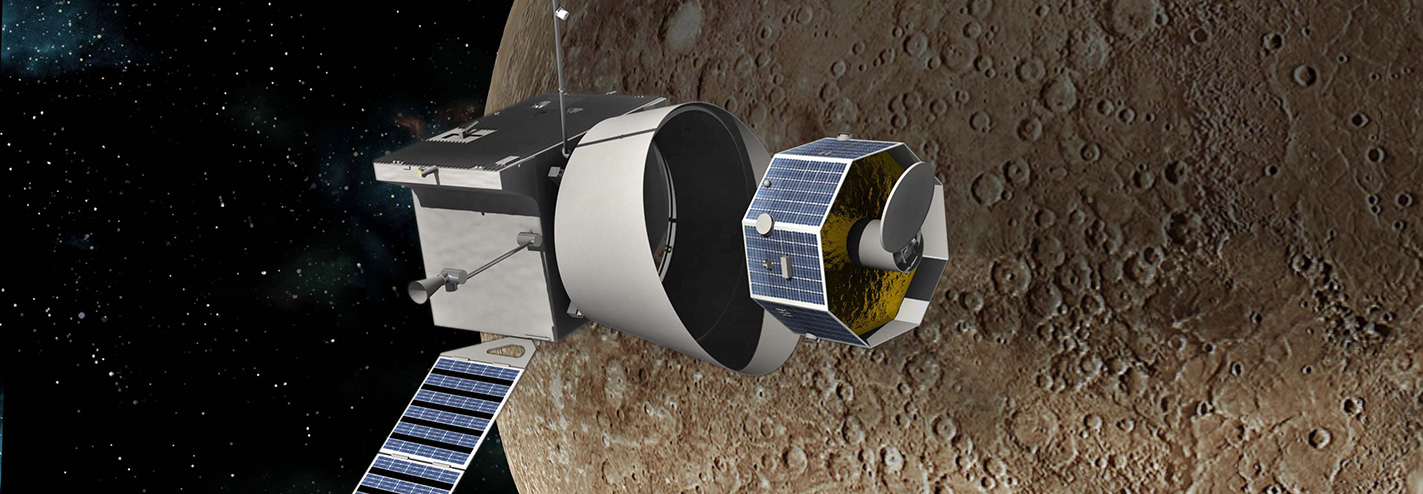

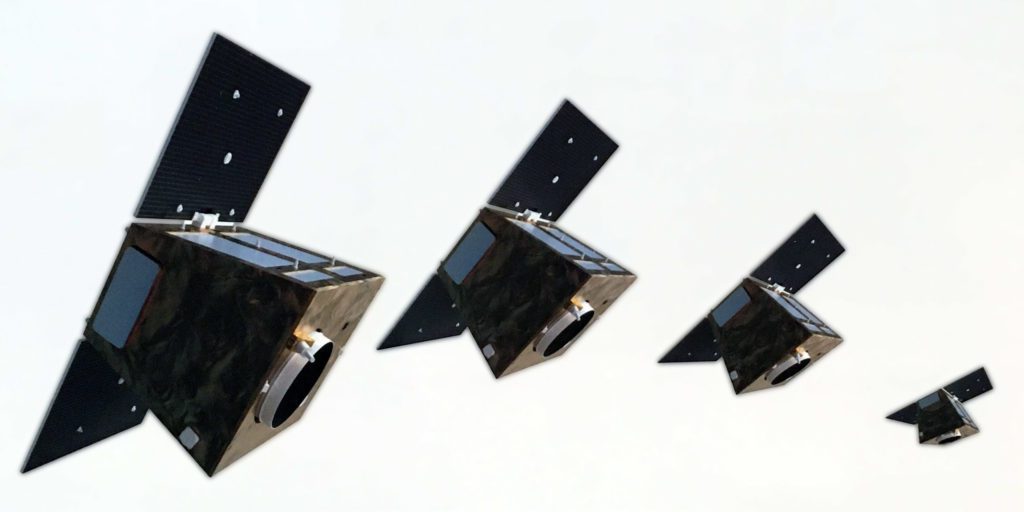

Examples of the many New Space programs currently in operation or under preparation are the Mars Exploration Program, which has been sending spectacular images from the surface of Mars since March 2021, or the 3D Optical Constellation (CO3D) program, which is supposed to provide a high-resolution 3D digital surface model of the earth. CO3D, initiated by the French Center National d’Etudes Spatiales (CNES,) will be comprised of four identical lightweight satellites produced by Airbus DS, which will provide stereoscopic images in order to create ultra-precise 3D maps of the surface of our planet.

EREMS – specializing in design and production of high-tech electronic aerospace equipment

One of the key contributors to Airbus and the CO3D satellites is EREMS, a French Enterprise located in the French high-tech area of Toulouse. EREMS is specialized in the design and production of high technology electronic equipment and associated software. Among the many successful projects handled by EREMS in its more than 40 years of history, is the design and manufacture of major equipment onboard SPOT6 and SPOT7 Observation satellites, the last 2 satellites of the SPOT (Satellite pour l’Observation de la Terre) program, which has been providing high-resolution optical images of the earth since 1986, or onboard the recently launched Very High-Resolution Pleiades Neo satellites. For CO3D, EREMS was selected to develop and produce several key electronic systems to be deployed in the four satellites.

To keep up with the growing challenges of New Space and to lay the foundation for a managed product development and production process of its sophisticated electronic products, EREMS has recently upgraded its PCB design environment to the Zuken’s 3D multi-board PCB design suite CR-8000 and its closely integrated design data and lifecycle management environment DS-CR.

“The space community is currently evolving with the arrival of the so-called New Space projects”, explained Gerard Dejonghe, President and CEO of EREMS. In these New Space projects, the industry is looking for cheaper, smaller, lighter, and more powerful equipment, which, in the area of in-flight electronic equipment is achieved through the use of the latest commercial off-the-shelf components, such as high-speed ICs, fast memory chips and fine-pitch components.”

Advanced requirement for high-speed design and component management

“Therefore, we needed a PCB design tool with solid high-speed design and 3D verification capabilities”, Gerard Dejonghe continued. “In addition, we realized that electronic components have a central place at EREMS and interact with many parts of our business. This starts in electronic engineering and sourcing and goes on to board layout and mechanical design departments through to manufacturing and quality assurance. Therefore, we wanted to equip ourselves with a tool that is capable of centralizing all component and design-related information.”

After thorough market research and evaluation, CR-8000 and DS-CR from Zuken emerged as the best fit. “CR-8000 enables us to manage the constraints related to fast signals and to carry out 3D verifications of our board layouts with the mechanical environment”, explains Laurent Dedecker, PCB & Packaging Design Manager at EREMS. “In addition, the tool has many interesting modules such as the specification verification of several different sets of manufacturing rules, or a design rule check DRC at the schematic level, which is useful for engineers to assess the feasibility of their design in the physical layout phase.

Another useful feature, in particular for the space industry is the ability of CR-8000 to manage different board level implementations from the same version of the schematic, using cheaper commercially available (but not certified) components for prototyping and testing purposes and replacing them with the certified components for the final realization.“

Right first time

The benefits of CR-8000 and DS-CR came to bear immediately during the deployment phase when the tools were used to create the first mock-ups of the high-speed boards EREMS developed for the CO3D satellites mentioned earlier. “Using CR-8000 immediately in a concrete project allowed us to come to grip with the tool and to set up the component library”, commented Laurent Dedecker, “and it allowed us to correctly manage the various constraints (skews, lengths, impedances, etc.) linked to the fast signals at the schematic level and to verify them at the PCB level.”

The ease of reusing all or part of a routing (on the same, as well as on a different board) was a great help in optimizing the routing times. “The CR-8000 tool has had an impact on the quality of the work done on the design of the project boards” concludes Laurent Dedecker. “Today, all the boards in the CO3D project are made with CR-8000, we have been able to remove board interconnection issues using the multi-board module, and thanks to the management of constraint we can predict the performance of our boards with confidence.”

So, when the Airbus-made CO3D constellation satellites will eventually be launched at the end of 2022, sending very high-resolution stereo images of the earth, a new era of measuring the earth in 3D will be chimed in thanks also to the contribution of EREMS and their efficient use of design tools provided by Zuken. By the way, additionally, to the Earth Observation & Science Programs, EREMS is also involved in the Solar System exploration: when the samples of the surface of Mars will be collected in stage 3 of the joint NASA and ESA Mars Exploration Program, the avionic interfaces of the Earth Return Orbiter will be controlled thanks to equipment provided by EREMS.

Read more in our EREMS Case Study by clicking below:

Download the full case study

- Blog

AI in PCB design is increasingly seen as a game-changer, with some predicting it could soon replace entire layout teams—but this view risks overlooking both the current limits of AI and the critical expertise engineering demands. At DesignCon 2025, experts from emphasized that AI's real value lies in complementing human judgment, not replacing it. Read more on our blog.

- Blog

Our new post explores the potential of augmented reality (AR) to transform everyday experiences in shopping, education, and navigation. It highlights how enhanced AR devices will offer immersive, interactive environments that blend the virtual and physical worlds.

- Blog

The field of PCB design continues to evolve as advancements in technology and shifting market demands push the boundaries of what’s possible. By 2025, several key trends are set to shape the industry. Find out more on our blog.

- Blog

Supply chain risk management is critical for electronics design. By integrating SiliconExpert with CR-8000, engineers gain tools to streamline component selection, manage obsolescence, and ensure design continuity. This integration supports efficient workflows, reduces costs, and mitigates supply chain disruptions.