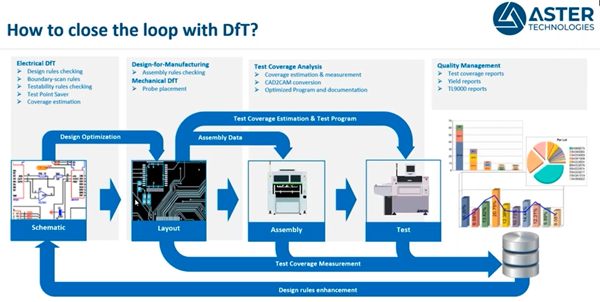

Traditionally, manufacturing and test constraints are only considered at the end of the layout phase, prior to transfer of the CAD data to production. With TestWay, users of Zuken’s CR-8000 can analyze their design at each stage of the design to delivery workflow.

What you will learn:

- Why it is important to test electronic boards

- Check testability rules at schematic design including Standard checks for In-Circuit, JTAG Boundary-Scan and Functional tests.

- Include internal checks to reflect the Corporate Design for Test (DfT) guidelines.

- Minimize the need for test points by simulating the test strategy prior to the layout.

- Optimize test probe placement at layout phase.

- Estimate test coverage for Automatic Optical Inspection (AOI), Automated X-ray Inspection (AXI), Boundary-Scan Test (JTAG), Flying-probe Test (FPT), In-Circuit Test (ICT) and Functional Test.

- Generate assembly, inspection and test programs for production.

- Use the digital twin to certify that implemented programs are fully aligned with early expectations on quality.

Learn from the expert

Christophe Lotz

President

Aster Technologies

With 35 years of experience in test and Design for Test, Christophe started as an engineer for the French Navy where he was in charge of writing military standards for design & test, for both boards and systems. Instead of books, containing advice, that designers must read, he decided to create tools that could automate the analysis. Christophe founded ASTER Technologies 28 years ago and now drives R&D to design and develop the state-of-the-art software tools to automate Design for Test, automatic coverage analysis as well as understanding Defect occurrences.