Calculating signal speed on a PCB

According to physics, electromagnetic signals travel in a vacuum or through the air at the same speed as light, which is:

Vc = 3 x 108M/sec = 186,000 miles/second = 11.8 inch/nanosecond

A signal travels on a PCB transmission line at a slower speed, affected by the dielectric constant (Er) of the PCB material. The transmission line structure also affects the signal speed.

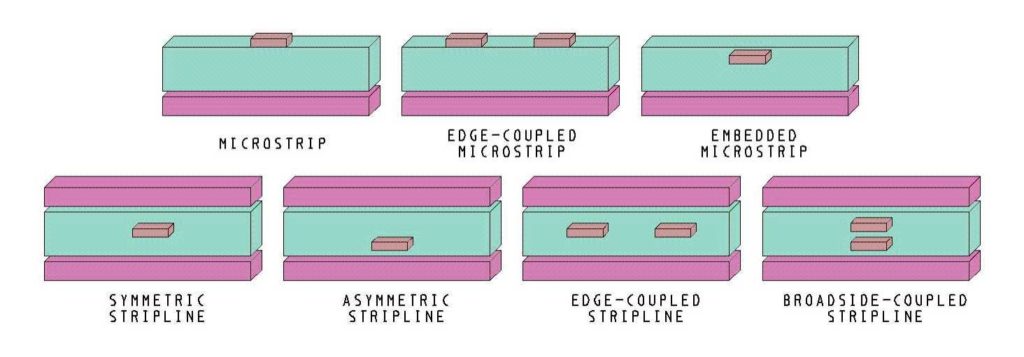

There are two general PCB trace structures [note*]: stripline and microstrip.

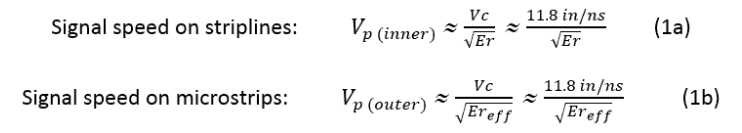

The formulas for calculating the signal speed on a PCB are given below:

Where:

- Vcis the velocity of light in a vacuum or through the air

- Er is the dielectric constant of the PCB material

- Ereffis the effective dielectric constant for microstrips; its value lies between 1 and Er, and is approximately given by:

Ereff≈(0.64 Er+ 0.36) (1c)

With those formulas, we know that the speed of signals on a PCB is less than the signal speed through the air. If Er≈4 (like for FR4 material types), then the speed of signals on a stripline is half that of the speed through the air, i.e., it is about 6 in/ns.

How to calculate propagation delay (tpd)

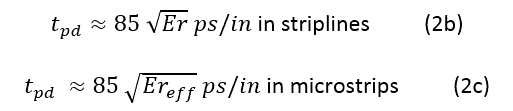

The propagation delay is the time a signal takes to propagate over a unit length of the transmission line.

Here is how we can calculate the propagation delay from the trace length and vice versa:

Where:

Where:

- Vis the signal speed in the transmission line

In a vacuum or through the air, it equals 85 picoseconds/inch (ps/in).

On PCB transmission lines, the propagation delay is given by:

Case study: Calculating trace length on a PCB

In order to be compliant with the specification of JEDEC, the maximum skew among all the signals shall be less than +/-2.5% of the clock period driven by the memory controller. All the signals of SDRAM are directly or indirectly referenced to the clock.

In this example, the normal FR4 material with a dielectric constant of 4 is used on the PCB with a differential clock rate of 1.2GHz (i.e., 833ps clock period):

Question: What is the maximum skew of the trace length for all the signals?

Answer: Max skew in time delay = +/-2.5% of the 833ps clock period = 20.825ps FR4 Er≈4, Ereff≈2.92

So, for strip lines, the maximum skew should be less than +/- (20.825/(85*SQT(4))=+/-0.1225 in = +/- 122.5 mil.

For microstrips, the maximum skew should be less than +/- (20.825/(85*SQT(2.92)) = +/-0.1433 in = +/- 143.3 mil.

Note*: Different microstrip and stripline structures will affect the signal speed, but only slightly.

Keep this information in mind the next time you’re calculating trace lengths; it should make the job a little easier for you.

References:

– Signal Speed and Propagation Delay in a PCB Transmission Line, Atar Mittal

– JEDEC

Also see:

CR-8000 – PCB Design Software Overview

Related Content

- Webinar

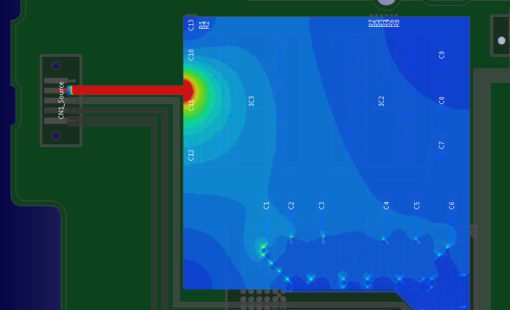

DDR5 is the latest generation of memory. In this joint webinar with Keysight Technologies, we’ll begin with pre-layout simulation, then transition to CR-8000. The design will then be verified by Electromagnetic (EM) simulation and system simulations in Keysight ADS, in order to build confidence in the final DDR5 design.

- Products

CR-8000 includes fully-integrated simulation and analysis tools to verify all aspects of your single or multi-board designs