Managing complexity

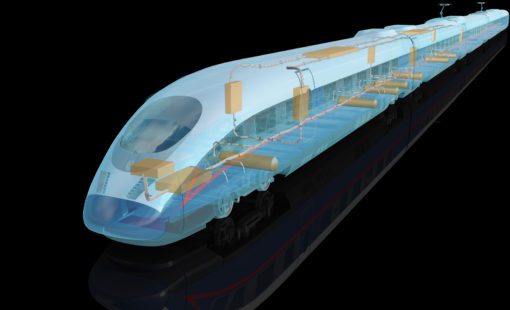

There’s no doubt about it: products are getting smarter. And that translates to increasing complexity for manufacturers. Traditional mechanical products suddenly require cabling and wiring, internet connectivity, and embedded software to function. Furthermore, the electronics and electrical systems integrated into today’s smart products must keep pace with the market’s broader demands. Mass miniaturization, rising pin counts, and high network bandwidth are but a few of those demands. Manufacturers don’t have it easy. They must still control costs, hit their product launch deadlines, and meet supplier and customer demands.

Systems engineering practices help organizations mitigate and manage product complexity. When applied to electronics and electrical systems, systems engineering takes on a whole new meaning. Using this approach, teams break down a product’s requirements and functions with a high degree of granularity and allocate them to functions, logical architectures, and physical items. In doing so, they gain traceability that enables them to explore the impact of any design changes on requirements and make the best decisions possible.

This post explores some of the different areas where systems engineering makes a difference and how systems engineering enables traceability.

Breaking down requirements and functions

Today’s systems engineering processes take place in the following order:

- First, systems engineers break down customer requirements, dividing them into smaller, discrete chunks of work. Systems engineers then shift to defining functions, which describe the product’s capabilities. Essentially, this stage provides a clear picture of customer demands and functionally how a product will fulfill those requirements.

- Second, progressive steps are taken to develop logical and physical architectures (the physical architecture being akin to the product structure or bill of materials). Systems engineers then allocate requirements and functions to the items contained in these architectures, creating a design envelope. In so doing, this creates the needed information for the design team.

- Lastly, systems engineers create and manage interfaces, which define how components or subsystems interact. Each subsystem’s engineering team designs to the definition of the interface. If the interface changes, design teams comply with the changes. The interface definition is an important piece of the logical architecture and minimizes integration issues further along the design process.

The design envelope

With the system definition complete, systems engineers provide each subsystem team their set of requirements, functions, logical architectures, and physical architectures. Together, these act as a set of constraints for the subsystem team. These functions and requirements include weight, dimensions, cost, performance, and memory size, for example. It’s unlikely to have design details identified at this stage. But this design envelope must contain a complete set of system functions and requirements; otherwise, a detailed fit-for-purpose design cannot be created.

Designs will evolve at different rates as teams begin to work. Commonly, systems engineering teams use spreadsheets and documents to create and manage the design. If an organization manages all the requirements, functions, logical architectures, physical items, and other system engineering factors using spreadsheets and documents, at a minimum its teams will struggle to understand which version is the latest—the one they must work from.

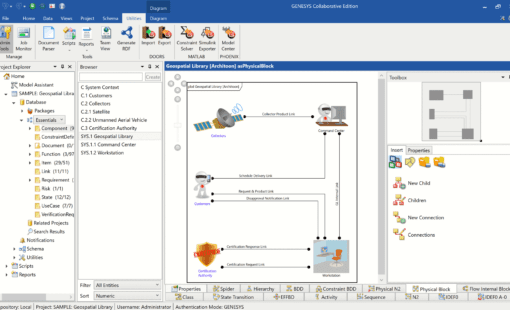

Alternatively, organizations can use a model-based system engineering approach that provides a single definition for everyone. With this approach, the design is represented by a model that contains and tracks requirements, function, logical architecture, physical items, and also the allocations and relationships among them.

Traceability for changes

From the product’s requirements and functions to its specific physical components, traceability across the design lifecycle allows organizations to track every change within the wider system.

When there is a connection between everything, everyone can explore the impact of changes. Systems engineers drill down and investigate how changes affect physical items in high-level requirements and functions. Designers tweak their detailed designs and immediately understand which requirements and functions are affected. Thanks to this granularity, engineers and designers are not overwhelmed by the complexity of the systems they create. What’s more, systems engineering enables traceability and provides value to organizations. The practices help them to understand how every change benefits their customers or broader business requirements.

Traceability is a crucial tool that allows organizations to perform trade studies and explore design changes from either the top down or the bottom up. It effectively creates relationships among a product requirement, a single component, and everything in between to foster understanding of the implications of any change. As a result, at the prototyping and testing stages, there are no nasty surprises. The MBSE-based process is as smart as the products, eliminating design errors and improving product quality.

Recap

- Systems engineering practices mitigate the complexity of today’s smart products. They help organizations achieve the traceability they require to meet customer and market demands.

- Systems engineers must break down system requirements and functions into a high level of granularity and provide interfaces to coordinate the design process across organizational divisions.

- Designers receive these detailed requirements and functions as a “design envelope” where configuration management is vital to maintain traceability across design iterations.

- Systems engineering enables traceability, which in turn, allows organizations to link system requirements and components to investigate the impact of changes across the design lifecycle. This mitigates the pressures associated with developing today’s smart products.

For more information about digital and systems engineering visit our website, or read more digital engineering blog posts here.

Related Content

- Solutions

Many companies have recently embarked on the “digital transformation” journey to become more efficient and competitive. A recent IDC study showed that 90% of small and medium-size businesses are budgeting for the digital transformation and 73% have begun the process. .

- Products

- Solutions

Digital Engineering requires a model-based design process that begins in Systems Engineering. Zuken acquired Vitech Corporation, a leader in Systems Engineering practices and MBSE solutions, with the intent of implementing an E/E model-based design process.