A drawing on paper remains evidently two-dimensional with little to no room for improvement. A PDF is a step up with the ability to pack a few layers of data but without the ability to have detailed instructions to drive manufacturing excellence.

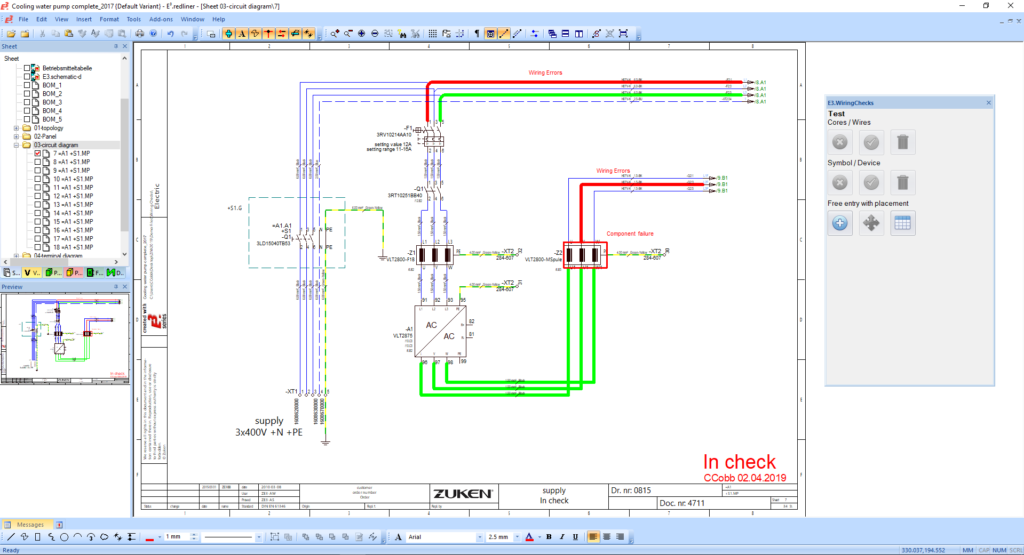

E3.WiringChecks works with your robust design data to create a step-by-step wiring and review system to accelerate deployment and manufacturing velocity. The system provides an efficient method to track, report and instruct a detailed process to drive your amazing designs towards an amazing product. Read on to learn how to revolutionize the electrical commissioning process using E3.WiringChecks. Here is a detailed look into each of the different GUIs this tool has to offer.

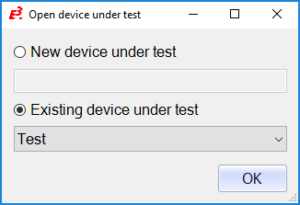

Creating a test/commissioning project

Main plug-in navigation box

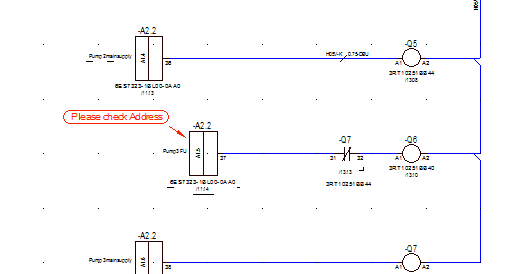

An easy-to-use interface enables users to learn the tool quickly and provides the much-needed productivity boost early in the process. The interface has buttons to accept or reject a device/symbol or wires as part of the checking process. All the events and entries are captured and run through the desired verification and approval process.

A drawing receives an ‘In-Check’ status when the user starts the test. That status is only removed once the designated supervisor receives the approval. The inaccurate and rejected items track details such as the type of issue, the reporting user, timestamps, and other information. These details are completely user-configurable to match your company’s electrical commissioning process.

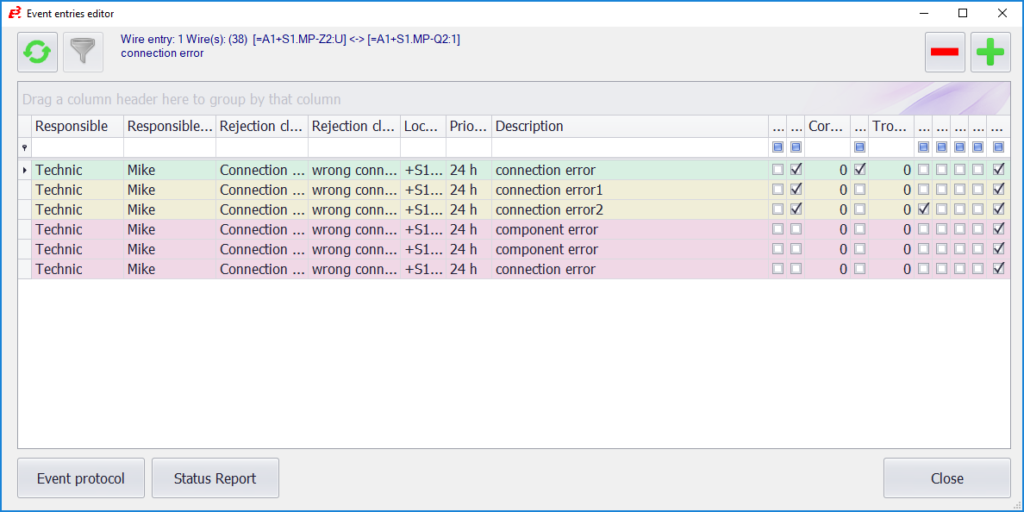

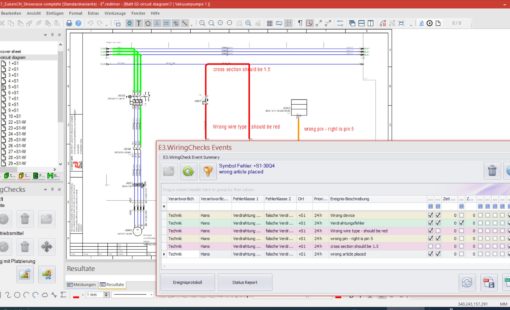

Event protocol box

Within the event protocol box, you’ll find colors that are easy on the eyes to represent the different states of the event along with intuitive check/sign-off procedures. The owner of the review can easily manage the project by exporting error logs, review status, and an overall event log.

With the ability to manage the project under review, you can easily ensure that all tasks are complete, and your review step is well on its way to completion, without the need to review the checking process.

Creating a repeatable electrical commissioning process

The E3.WiringChecks plugin gives you the ability to use E3.series project data for commissioning/checking, helping to replace manual and paper-based procedures. You’ll be able to create a repeatable, automated electrical commissioning process to generate documentation during design checking including error logs, stats and event reports to keep your team on track.

Expandable documentation

E3.WiringChecks gives the ability to export all related event protocol, error logs, and status report documents via an Excel spreadsheet. This can greatly enhance the reliability in the manufacturing, assembly, and deployment processes. You have complete control of the customization of these documents to meet your specific process requirements and input information in your ESO process.

With this intuitive way of documenting and tracking design error reviews and responsibilities, E3.WiringChecks helps build the link to your digital thread by connecting the ideation process and end-of-life process.

As part of a robust solution, E3.WiringChecks is guaranteed to help bring you closer to manufacturing excellence to drive your amazing designs towards an amazing product.

Watch our on-demand webinar “Paperless testing and commissioning with E3.WiringChecks” to learn more.

*E3.WiringChecks is a plug-in for E3.redliner

Related Content

- Products

By using E3.redliner, modifications made during assembly can be added as a graphical overlay to the original E3.series design or to a special viewer file.

- Products

E3.WiringChecks assists the testing of fully wired machines, vehicles and control cabinets before and during the start-up phase.

- Products

E3.series is a true concurrent electrical engineering environment supporting advanced requirements for electrical documentation, cabinet and wire harness design and manufacturing outputs.

- Press Release