The only thing I like more than a good win-win situation is when there’s a win-win-win. That was the conclusion I drew when I discovered how Pantec Automation, which designs and manufactures control systems for machines, used E3.series to almost halve its manufacturing times. And they can now send 95% of work to their shop floor without design engineering intervention. The company is also helping its customers be more competitive. Here’s a breakdown of their before and after figures:

Now I’ll talk you through how they achieved this…

Under threat

An odd custom

The machine builds are mostly unique, as specifications such as physical dimensions, roller speeds and the number of encoders or other sensors will be set to meet the requirements of a particular plant or factory. Not surprisingly, the development and build of a machine for a plant was a design intensive and time-consuming task. For instance when liaising with a customer, the machine builder’s salespeople needed to understand the customer’s requirements. Their engineers would get heavily involved, because they knew what was required to meet the requirements. They also knew which parts of a machine would work with others. Pantec would then quote for the supply of control cabinets, HMIs and cabling; all before the machine builder could get to their customer. Then there was the build time, and the project turnaround time (from machine order to commissioning) was about 15 weeks.

Got to be a better way

The key questions were:

- How could the machine builder’s sales people be better supported, whilst simultaneously reducing their design engineers’ time?

- How could Pantec shorten the time to produce cabinets, HMIs and cables, and so reduce costs?

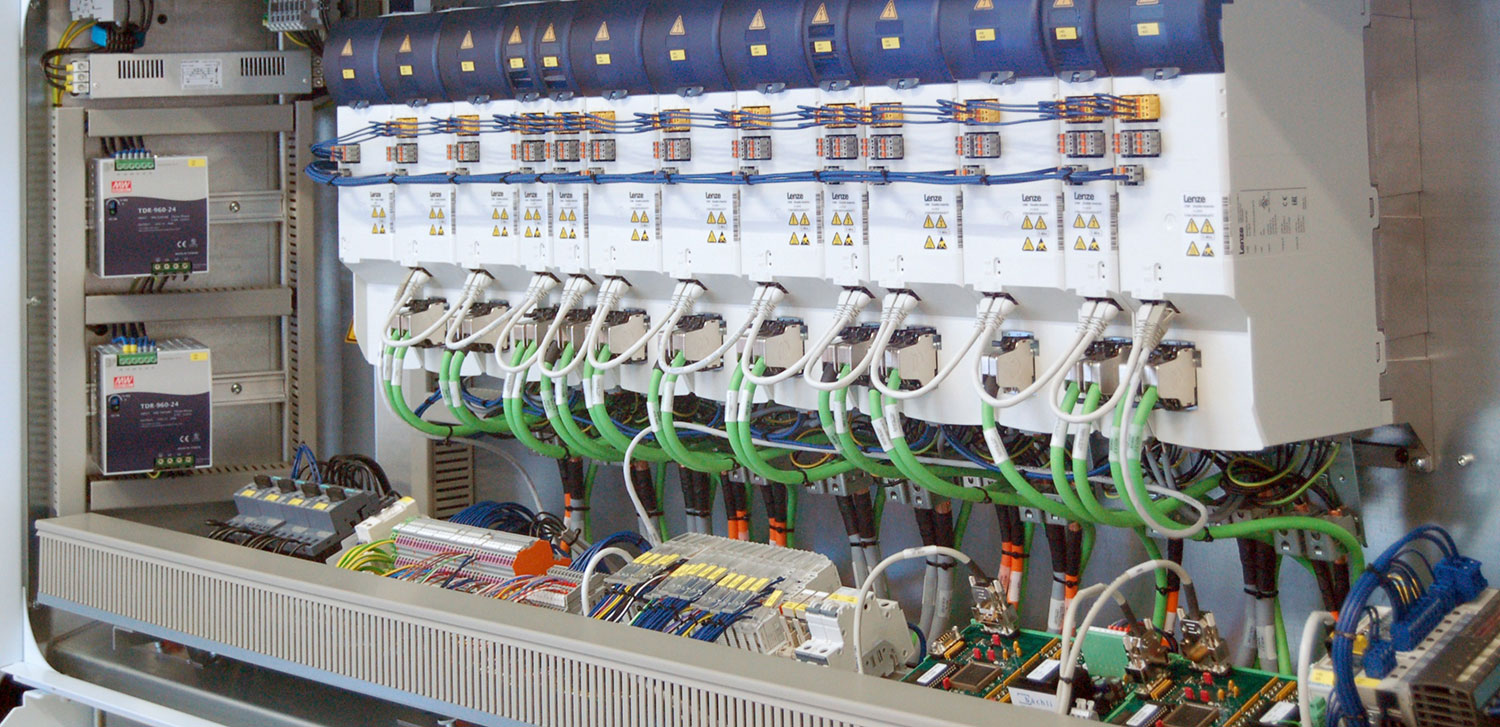

The Configurator presents a list of valid variants and options, controlled by a logical ‘decision tree’, which makes for a very efficient selection process. Its Configurator then outputs a set of unique order numbers for the machine being specified, which ties in with Electrical Planning (i.e. electrical schematics and BOMs within E3.series) and Pantec Automation’s ERP /PPS system (for parts lists and sales orders etc.). There will typically be some bespoke work required but from Pantec Automation’s perspective, 95% of the work needed to meet the customer’s unique overall requirements can go straight to the company’s experienced assembly personnel with little or no design engineering intervention; because it is all policed by the Configurator.

Time will tell

Project turnaround (from machine order to onsite commissioning) used to take around 15 weeks:

1 week for electrical planning, 8 weeks for sourcing, 5 weeks for assembly and 1 week for testing. Now, with E3.series, project turnaround is about 8 weeks: 0 weeks for electrical planning (it’s not needed), 4 weeks for sourcing (improved stock management due to the availability of pre-assembled modules), 3 weeks for assembly (clearer assembly documentation, so fewer calls to engineering are needed) and 1 week for testing.

This reduction from 15 to 8 weeks for all activities between machine order and commissioning equates to almost 50%.

Related Content

- Case Study

When Pantec Automation’s customers faced pressure from low-cost counterfeit machinery, they realised the best way to fight back was to help customers reduce their own costs. Through wholesale efficiency improvements achieved by expanding its use of Zuken’s E3.series and integrating it into its ERP/PPS, Pantec Automation enabled its customers to better serve end-users.

- Solutions

- Products

E3.series is a true concurrent electrical engineering environment supporting advanced requirements for electrical documentation, cabinet and wire harness design and manufacturing outputs.