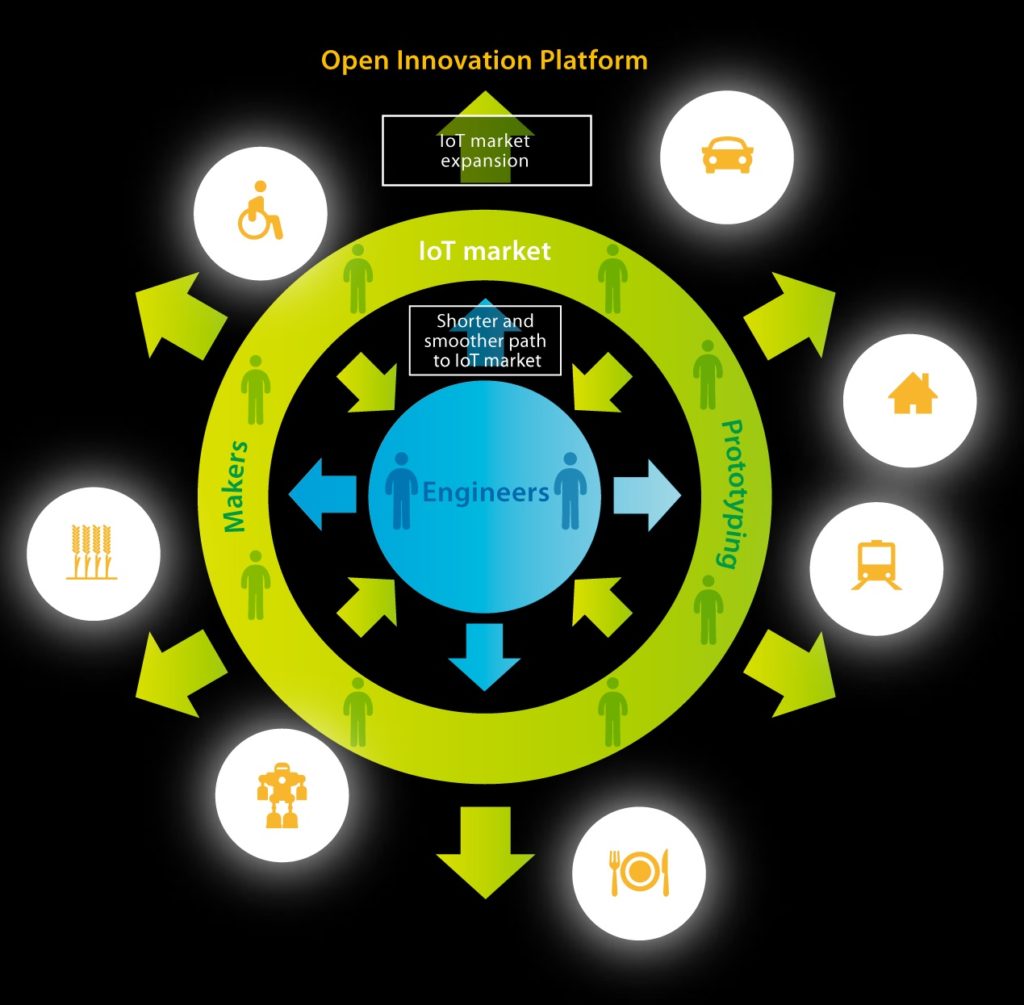

Japan is one of the first countries to face the combination of challenges such as energy issues, population decline and an aging society. Solving these problems with the benefit of the Internet of Things (IoT) could generate future business opportunities as well as meeting the demands of society. Enabling as many people as possible to try out new ideas, and encouraging them to develop diverse products, will broaden these opportunities. The Trillion-Node Engine is a platform for realizing this objective.

Zuken is participating in the Trillion-Node Engine project in an effort to link the creativity of “makers” with leading-edge mass production technology.

Members of the “maker movement,” are a group of small-scale inventors who have been liberated from dependence on big manufacturers by technology, according to Chris Anderson in his best-selling book Makers: The New Industrial Revolution. Anderson describes makers as today’s entrepreneurs, using open source design and 3D printing to bring manufacturing to the desktop.

The creativity of “makers” is the driving force of IoT

The latest paradigm shift in electronics involves innovations such as IoT, in which all objects are interconnected via the Internet, and cyber- physical systems (CPS), in which artificial intelligence (AI) is used to process real data obtained from sensors embedded in these objects. Electronic devices, collectively referred to as IoT terminals, are projected to reach 50 billion in 2020 and 1 trillion by the 2030s. Looking ahead to that era, Zuken is participating under commission from the New Energy and Industrial Technology Development Organization (NEDO) in research and development of a Trillion- Node Engine, a cross-cutting technology development project to promote IoT.

According to project leader Professor Takayasu Sakurai of the Institute of Industrial Science at The University of Tokyo:

“One trillion nodes could mean, for example, that there are one million types of sensors, with each type of sensor on one million individual devices. IoT terminals are likely to be so – called long tail products, an extremely wide variety of products consisting of combinations of sensors, actuators, communications modules, microcomputers and power supplies, depending on the application.”

It is impractical for conventional semiconductor manufacturers, with a business model premised on large- scale production, to cover the entire expense of developing these products.

Meanwhile, “makers” ― individuals who use open innovation to commercialize products that address consumer needs — are gaining attention as a new trend in manufacturing. Professor Sakurai stresses the significance of the Trillion-Node Engine in this regard:

“They [makers] are also likely to play a major role in IoT by giving shape to familiar ideas rooted in their individual lives, which is difficult to do in a corporate framework. However, that will require an environment in which anyone, regardless of their skills, can immediately try out ideas, on the spur of the moment, free from complicated procedures. When that happens, more than a million applications will be developed. Such an environment will provide opportunities to corporate engineers as well.”

A platform that enables everyone to experiment on ideas and technologies

The Trillion-Node Engine has been designed as an integrated electronics platform that allows for diverse systems. Simply put, various systems can be constructed by connecting hardware modules (“leaves”) in a manner similar to assembling LEGO® blocks. There are already products for makers that take a similar approach (Arduino, Raspberry PI, mbed and others). However, compared with these products, the project targets a significant reduction in size to 1/100th of the volume, 1/ 10 of the power consumption, and the facilitation of configuration outside a factory – targets which have already been achieved by the project.

Users do not need to solder or employ specialized processing machinery. Furthermore, expertise in electronic engineering is not required. During assembly, the “leaves” can be connected horizontally like a bracelet, as well as by stacking. In addition, the software can use tens of thousands of Arduino applications, and will also support other open software platforms in future. Professor Sakurai has great expectations:

“Even prototypes for systems that used to take six months to make, for example, can be ready in around an hour. On such a platform, competition among superior technologies and ideas will lead to the development of valuable applications and services.”

Solutions that provide a bridge between prototypes and mass production

The Trillion-Node Engine is a platform that provides a bridge between highly creative makers and venture companies on the one hand, and semiconductor companies that excel in large-scale mass production technologies on the other. Professor Sakurai points out:

“For example, if a system composed of four “leaves” succeeds as an IoT terminal, costs can be markedly reduced by making a single board containing the system using mass production technology. CAD will play a crucial role in this process.”

Zuken’s CAD products have achieved advanced functionality and a high level of reliability that meet the demands of professionals in the electronics design and manufacturing field. We are currently planning a solution for makers in the form of a tool that anyone can use easily, but at the same time provides a smooth path to the mass production stage.

With challenges such as a low birth rate, an aging population and obsolete infrastructure, Japan is aiming for a better future by using IoT and AI. An open platform involving various players, from makers on the individual level to manufacturers of high-quality materials and components, and large enterprises with advanced semiconductor technology, will play an important role.

Related Content

- Webinar

In recent years, the design of Internet of Things products became a major topic of interest. But mostly when discussing IoT aspects, the focus is on the software/application and the business-model side, neglecting the fact that PCBs are the core of - almost - every IoT device, with dedicated requirements for the design and analysis process.

- Press Release