Many companies struggle with the rising complexity of today’s smart, connected products. Such products span many engineering domains and require multiple prototyping and testing rounds. The potential for complications and log jams is vast. Still, you can nip them in the bud with the right mix of systems simulation, systems engineering, and engineering co-design across domains.

Many companies struggle with the rising complexity of today’s smart, connected products. Such products span many engineering domains and require multiple prototyping and testing rounds. The potential for complications and log jams is vast. Still, you can nip them in the bud with the right mix of systems simulation, systems engineering, and engineering co-design across domains.

Multi-domain systems engineering matters

Today, deadlines are tighter and project requirements more demanding. Engineers have to iterate and explore different ideas to meet these needs, and that is hard enough. But the multidisciplinary nature of engineering makes things even more complicated: All teams must now work together to form a cohesive system.

Luckily, some methods can help. In this post, we’re going to look at ways your organization can master engineering co-design.

MBSE for engineering co-design

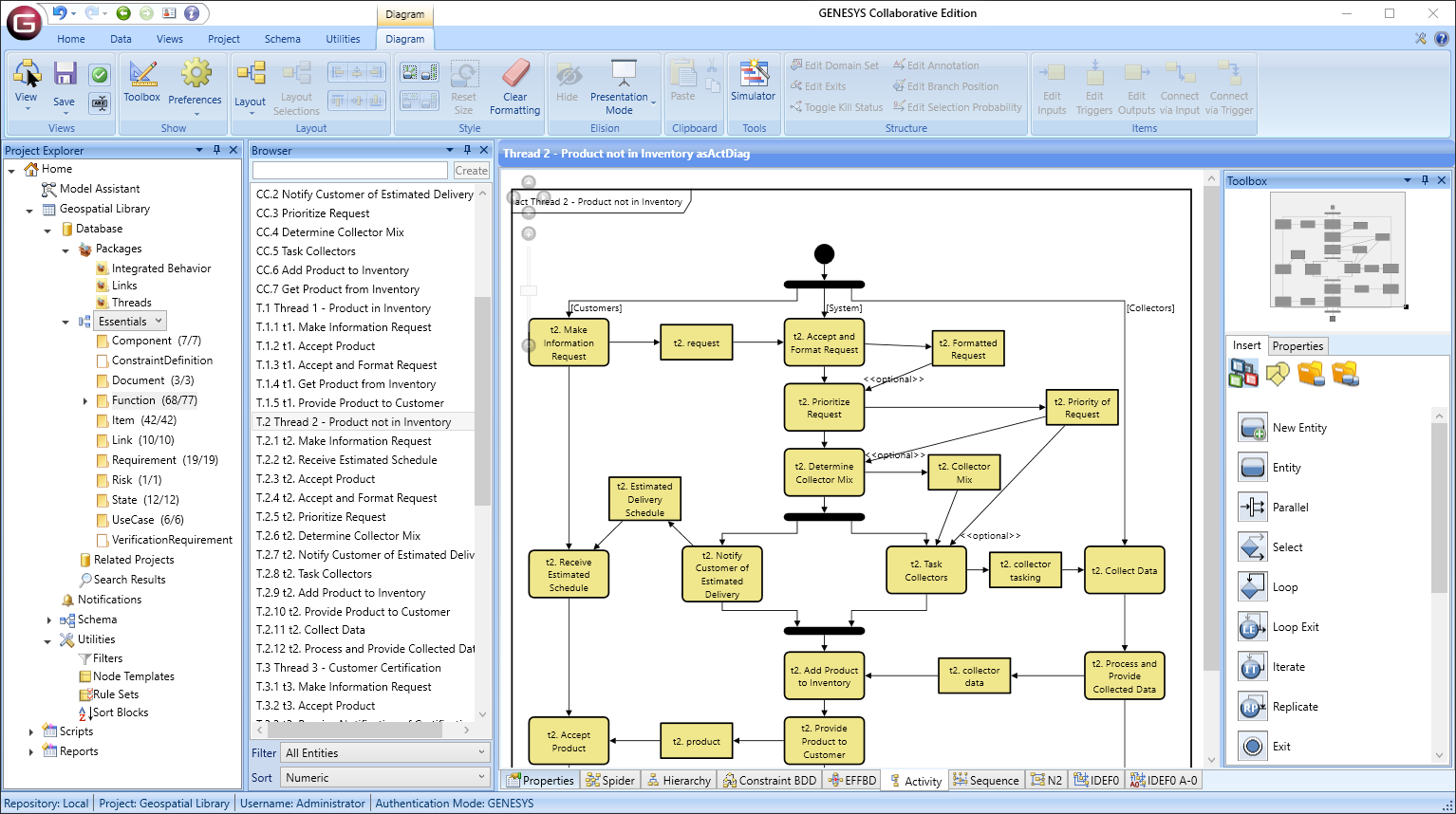

Model-based systems engineering (MBSE) is an ideal solution for simplifying co-design. Using this established design technology, engineers develop and manage a systems definition in a virtual environment to test different design ideas. It’s more definitive and safer than employing spreadsheets and documents. MBSE helps your organization meet its product requirements and project targets far more easily.

MBSE also unlocks innovation across your design lifecycle. You can now iterate over many more design possibilities, which is entirely infeasible when you’re conducting real-life tests.

MBSE creates a central, unambiguous definition of your systems using a model. This model defines the requirements and functionality of your product and therefore provides your teams with a single source of truth. Contributors can now design freely and within your requirements.

Another benefit is that when someone makes a design change to your product, the model updates in real-time. All changes made to your model are communicated across every team in an unambiguous way. So now everyone is on the same page and has the most up-to-date information. The end result? Fewer errors and an accelerated design process.

MBSE enables widespread collaboration between your engineering teams. It defines the boundaries and interfaces between different design teams and subsystems. MBSE’s ability to communicate the impact of any design changes to all stakeholders is a game-changer. When every team has access to an up-to-date model at all times, they can work together in the right direction while enabling engineering co-design.

How systems simulation helps

Systems simulation is another valuable tool for engineering co-design at your organization. It uses 0D and 1D analyses to predict your system’s behavior using a virtual environment. Here, numeric models emulate interactions across multiple variables and domains within your system.

Systems simulation works across the entire design. It can predict the performance of the whole system, based on the work from many different engineering teams, and can simulate various real-world scenarios. In other words, this provides a connected engineering co-design space.

Teams can test different areas of the design to understand the impact of a change across the entire system. Testing boosts the visibility across your systems engineering lifecycle.

Systems simulation improves every stage of your product development lifecycle. Throughout the development process, systems simulation is a robust verification tool. Engineers can test their ideas and see the impact across the entire design. Sometimes the smallest design changes can have major repercussions for your final product. As the design of the system progresses further into development, the systems simulation verifies that everything still works as intended.

But without systems simulation, you may only discover issues when you get to the prototyping and testing phases. And resolving such problems this late in the development process requires an excessive amount of time and money.

Systems simulation uncovers issues earlier. Therefore, your design teams can take corrective action, avoiding late-stage delays and costs. This also frees your engineering teams from time-consuming respins. Instead, they are free to work on value-added tasks, boosting innovation across your organization.

Engineering co-design for all

As products get smarter and more interconnected, engineering co-design is more critical than ever. You can improve your organization’s capacity for co-design with methodologies like MBSE and systems simulation. MBSE provides a central, unambiguous definition of your systems, so all contributors can design from the same version. Systems simulation lets your engineers test and identify issues early in the design process. And the result is significant time and cost savings that affords your organization a clear competitive advantage.

For more information about MBSE, systems engineering, and digital engineering, visit our website or see our Digitial Engineering on-demand webinars for more information.