From boardrooms to press briefings, conversations around AI in PCB design have grown louder—portrayed by some as a transformative force poised to reshape engineering workflows. There’s a growing belief—especially among decision-makers—that AI is on the brink of designing printed circuit boards on its own. Some even suggest entire layout teams might be “streamlined” in favor of automation.

But there’s a risk in that kind of thinking. It overlooks where AI really is today—and what PCB engineering actually demands. On paper, replacing engineers with algorithms might seem efficient. But in practice, it can strip away the hard-earned insight and judgment that make complex designs reliable. Once that’s gone, getting it back isn’t easy.

What’s actually unfolding is a shift from speculative AI headlines to practical enhancements that complement engineering workflows—particularly in constraint handling and layout strategy.

This tension between potential and misconception was at the heart of a recent expert panel hosted by Aspencore, the US publishing company that publishes, among others, EE Times, Electronic Design News, and Embedded.com, during DesignCon 2025 (Santa Clara, California, Jan. 28-30, 2025) —one of the industry’s leading conferences for high-speed system and PCB design.

The session, moderated by Dr. Eric Bogatin, professor in the Electrical, Computer & Energy Engineering Department at the University of Colorado, Bolder, brought together thought leaders from Zuken, Siemens, Cadence, and Samtec to examine the evolving role of AI in electronic design. Dr. Kyle Miller, Technology Strategy Manager at Zuken, joined the discussion to share how AI is being integrated into PCB workflows—and why managing expectations is just as important as managing data.

What emerged was a clear consensus: AI is a powerful enabler, but it must be positioned as a collaborative assistant—not a replacement for engineering expertise. Without the proper context and oversight, AI can reinforce incorrect assumptions or deliver flawed results with unsettling efficiency. In complex domains such as signal integrity and power distribution, where non-linear behavior and system-level interactions dominate, the engineer’s judgment remains irreplaceable.

From Assistance to Intelligence: Evolving AI in PCB Design

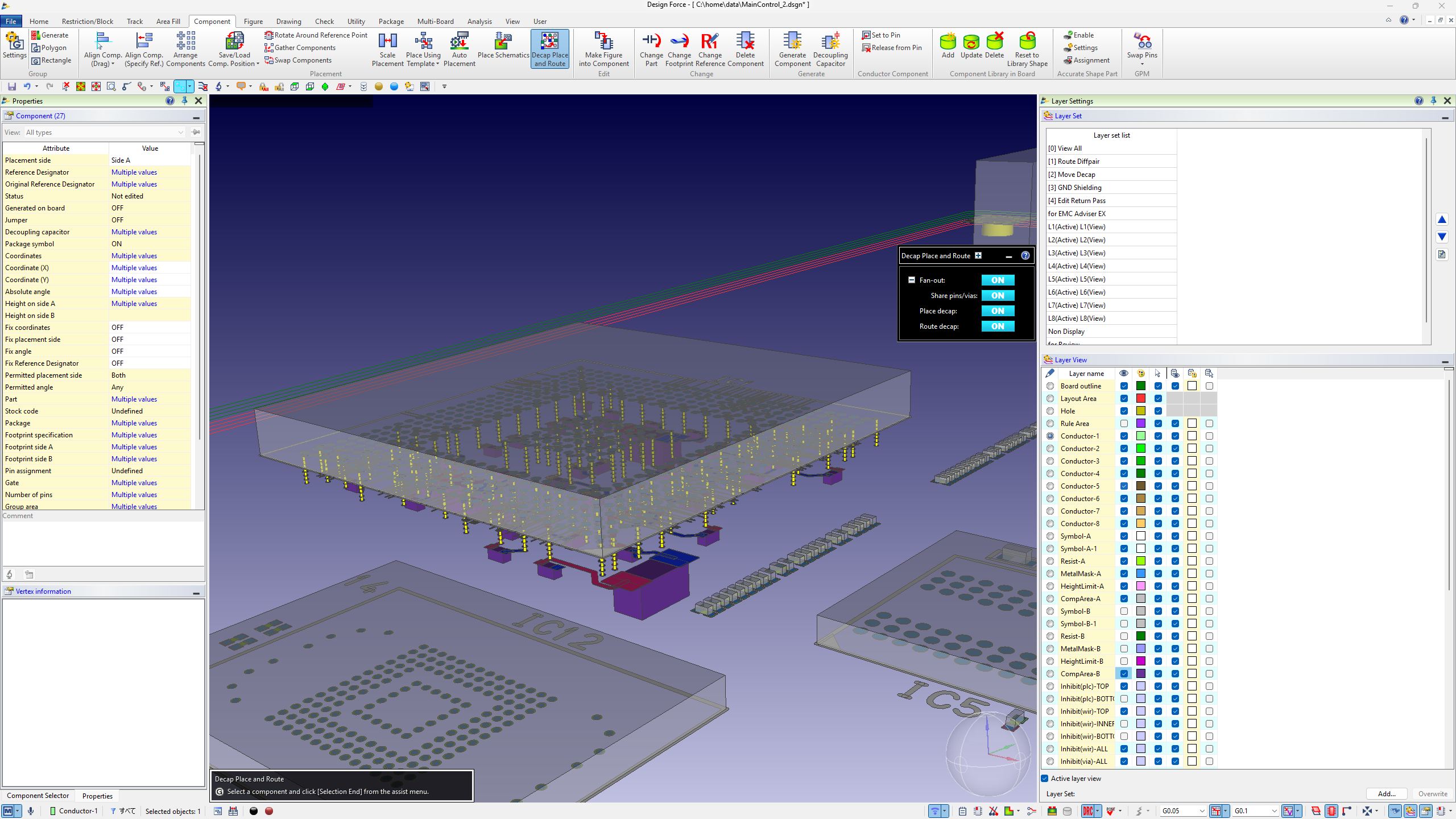

Building on this perspective, Zuken’s CR-8000 2025 release represents a carefully measured step toward integrating AI in a way that supports—not sidelines—engineers. It introduces AI capabilities precisely where they add the most value: helping streamline routine decisions, capturing reusable layout intelligence, and accelerating workflows that are shaped by carefully defined electrical and physical constraints.

In Design Gateway, CR-8000’s schematic and system-level front-end, AI assists with the definition and verification of electrical constraints. It analyzes existing project data to recommend constraint strategies, check for consistency, and flag missing definitions. AI also accelerates the setup of design rules in complex, multi-board systems and helps ensure constraint sets are complete and aligned with project scope. Its function is advisory, supporting engineers without altering circuit topology or behavior.

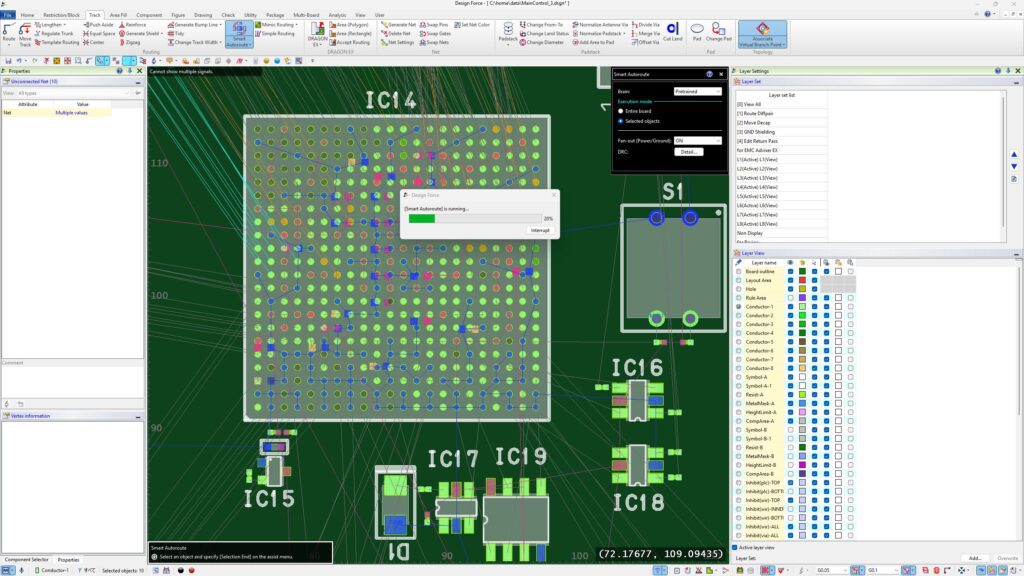

That layout phase, conducted in Design Force, is where AI becomes a more interactive partner. The placement and routing engine in Design Force now leverages AI to assist with component positioning and path planning, offering suggestions grounded in historical layout knowledge and current electrical constraints. It evaluates factors like trace length, via count, mechanical fit, and thermal zones to propose placements that reduce rework later in the process.

Notably, AI in Design Force also enhances manual layout operations. When designers begin routing high-priority nets or critical signal groups, AI can intelligently assist in completing partially routed connections, maintaining design rules while avoiding congested or thermally sensitive areas. This mode of operation preserves creative control, allowing designers to guide the process while benefiting from machine-speed insight into layout efficiency and compliance.

All AI-driven decisions remain bound by the rules defined in Design Gateway. Through real-time interaction with the constraint browser, Design Force continuously checks routing and placement choices for compliance, providing immediate feedback and correction paths if violations are detected.

Underlying all of this is Zuken’s structured knowledge model. Functionality levels allow the system to recognize reusable design blocks—such as power modules or memory sections—while brain files store proven strategies and preferences derived from previous designs. These are not static templates but dynamic, evolving knowledge assets that grow with each project and can be shared across teams to ensure continuity and consistency.

Looking Ahead: AI with Engineering Discipline

The CR-8000 2025 release is not a technological endpoint. It is a foundation. By embedding AI into real workflows—from constraint definition to physical implementation—Zuken is setting the stage for broader, deeper integration in the years to come.

The long-term vision includes expanding AI support into simulation setup, variant management, and cross-domain collaboration with mechanical and manufacturing systems. But the core principle remains: AI must amplify engineering expertise, not bypass it.

As the industry continues to explore the promise of AI in PCB design, success will depend less on algorithms and more on alignment—with process, with people, and with the standards of precision and reliability that define this discipline. CR-8000 2025 is an important step in that direction—one that brings intelligence to the workflow without removing the engineer from the loop.

- Blog

AI in PCB design is increasingly seen as a game-changer, with some predicting it could soon replace entire layout teams—but this view risks overlooking both the current limits of AI and the critical expertise engineering demands. At DesignCon 2025, experts from emphasized that AI's real value lies in complementing human judgment, not replacing it. Read more on our blog.

- Blog

Our new post explores the potential of augmented reality (AR) to transform everyday experiences in shopping, education, and navigation. It highlights how enhanced AR devices will offer immersive, interactive environments that blend the virtual and physical worlds.

- Blog

The field of PCB design continues to evolve as advancements in technology and shifting market demands push the boundaries of what’s possible. By 2025, several key trends are set to shape the industry. Find out more on our blog.

- Blog

Supply chain risk management is critical for electronics design. By integrating SiliconExpert with CR-8000, engineers gain tools to streamline component selection, manage obsolescence, and ensure design continuity. This integration supports efficient workflows, reduces costs, and mitigates supply chain disruptions.