Smarter design workflows. Stronger variant control. Seamless collaboration.

E3.series 2026 introduces a significant evolution in electrical and fluid design productivity, combining intelligent automation, advanced variant control, and new tools for seamless, real-time collaboration. Whether designing complex cabinet layouts, managing cable assemblies, or integrating ECAD with PLC and MCAD workflows, this release delivers meaningful performance gains across the entire development cycle.

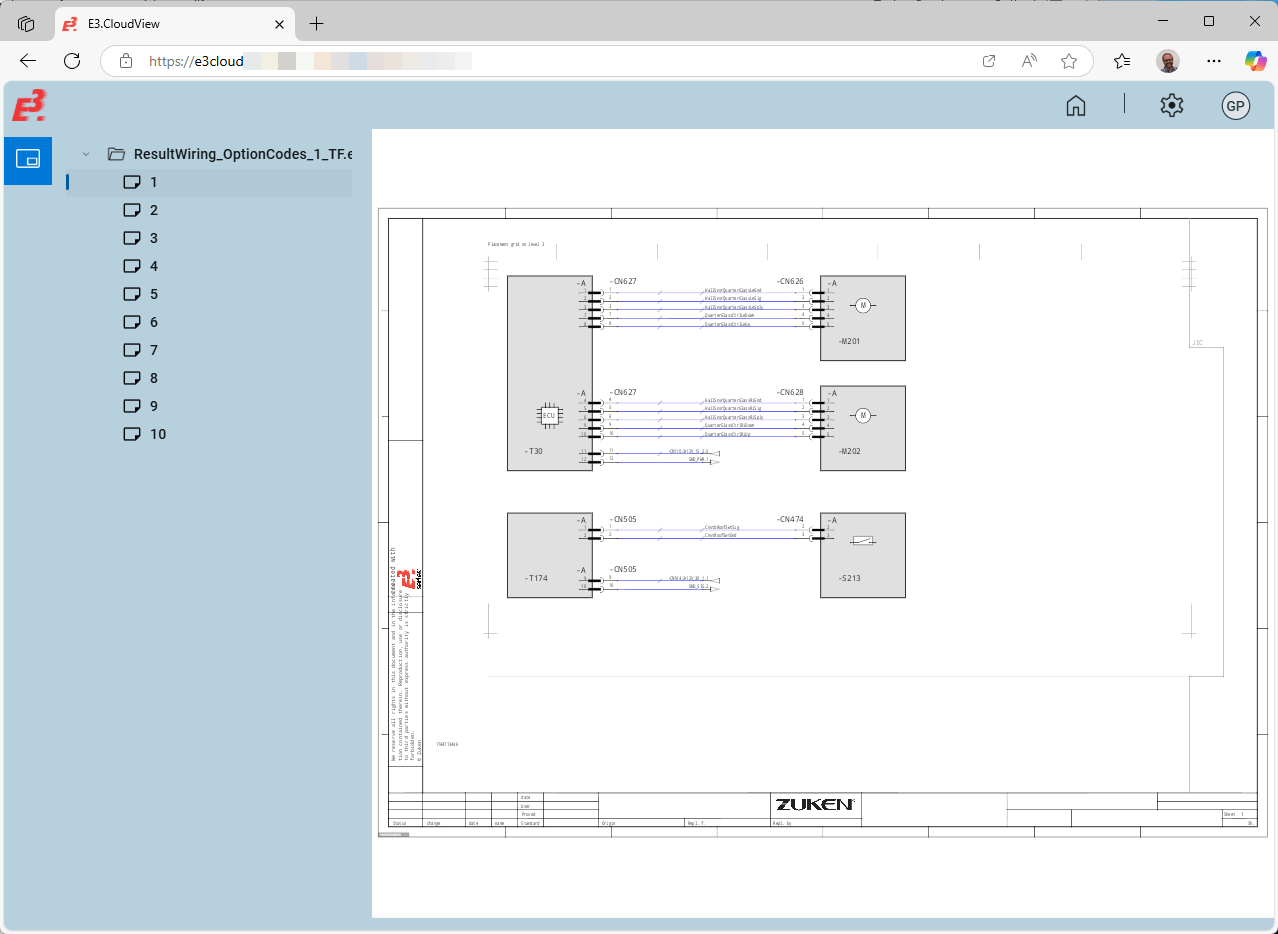

New cloud storage and viewer: Store E3.series projects centrally and access them via supported web browsers like Edge, Chrome, and Firefox

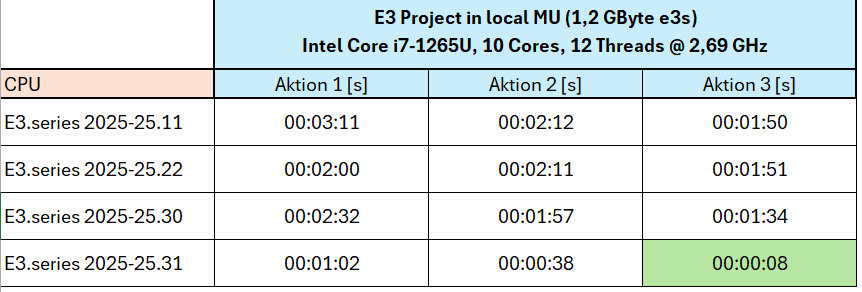

Faster variant switching in large projects: Activate and deactivate options with significantly improved performance and reduced loading time

Enhanced Variant and Option Management

Managing electrical projects with extensive variants and configuration options has become significantly easier. The updated variant handling functionality includes a redesigned user interface with better structure, faster filtering, and improved performance for large datasets. Engineers can now visualize, select, and manage variant-specific logic more clearly—supporting product platforms with hundreds of configuration options. This enables faster iteration and reduced errors in variant-rich industries such as machinery, automotive, and aerospace.

Real-Time Multi-User Collaboration

The 2026 release improves how multiple users work on the same project in parallel. New visual indicators show who is currently active and where they are editing, helping avoid overlapping changes and unintentional conflicts. Project filtering can now be applied on a per-user basis, allowing individuals to focus on their specific area of work. This live collaboration environment reduces delays, improves communication, and supports faster completion of tasks—especially in large teams working under tight development schedules.

When opening a multi-user project, users can now filter by project name or description to quickly locate the relevant project

Easily find and update attribute values or texts using the main menu or Ctrl+H. Highlighted results, smart filtering, and support for case-sensitive search streamline editing across complex designs.

Precision Editing with Search and Replace

A redesigned search-and-replace tool allows high-precision updates to attributes, texts, and metadata across entire projects. Users can apply powerful filters and conditions to control which objects are affected, minimizing the risk of unintended changes. This is particularly useful for global naming updates, compliance-driven attribute changes, or bulk edits after library updates. Combined with the new selective component update function, teams can implement changes in a controlled way without disrupting validated design sections.

Editable Cable Lengths in the Graphical Interface

Cable lengths can now be edited directly in the graphical environment using dimension lines, making adjustments more intuitive and traceable. This feature is especially useful for finalizing cable assemblies after layout changes or meeting updated manufacturing specifications. Rather than navigating through separate property menus or spreadsheets, engineers can now click and modify lengths in context, ensuring greater accuracy and reducing the time needed for physical validation and documentation updates.

Changes to dimension values are automatically applied to the manufacturing length in the connection properties—speeding up length edits without opening additional dialogs.

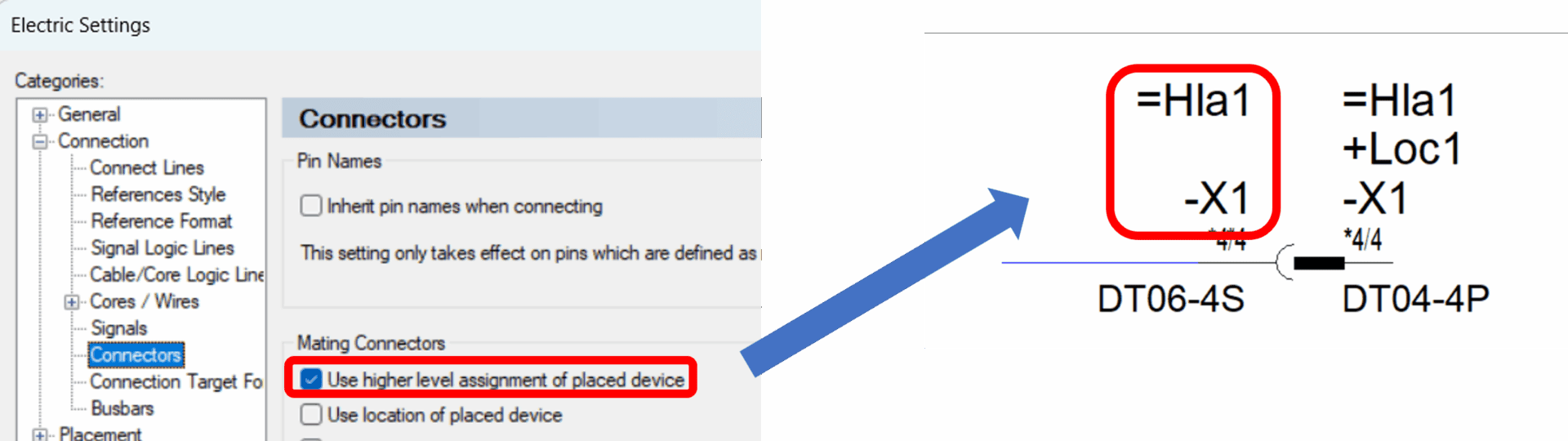

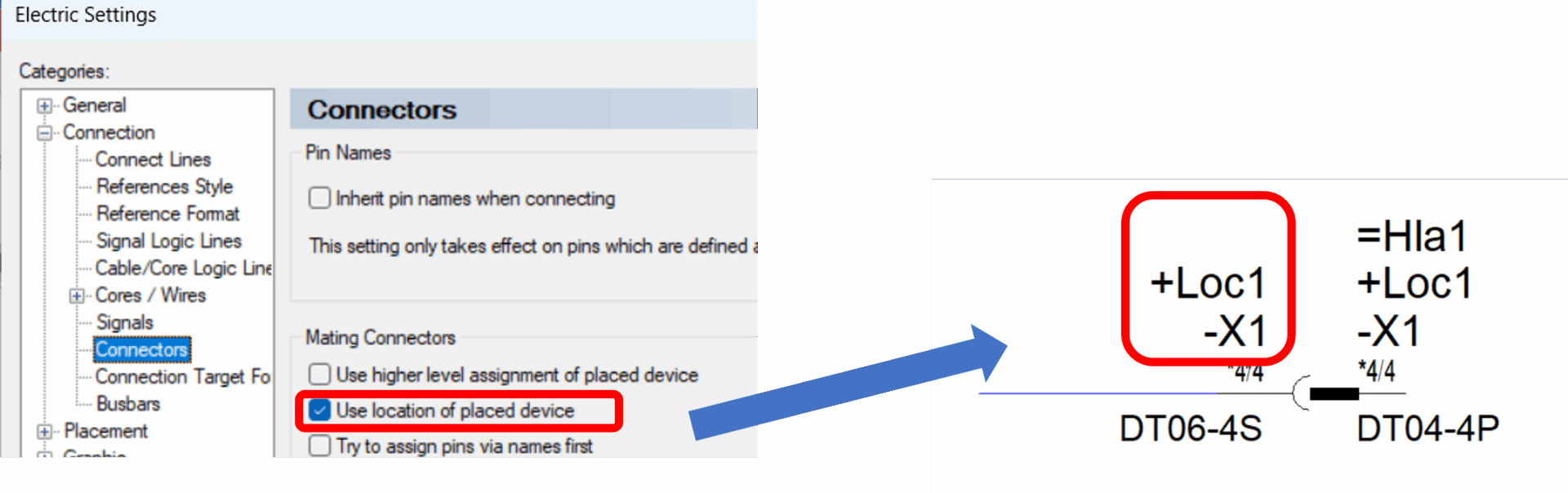

Device names can be generated based on either “Higher Level Assignment” or “Location” using separate configuration checkboxes

Automatic Naming of Mating Connectors

Connector device names can now be generated automatically based on configurable rules such as hierarchical level assignment and location. This eliminates manual naming effort and improves consistency—especially in large-scale designs with high connector counts. By automating the naming process, engineers can ensure alignment with internal standards and reduce the risk of human error, helping to maintain clean, structured data for downstream processes such as ERP integration or harness manufacturing.

Geometry-Oriented Cable Routing in E3.panel

Routing paths in E3.panel now take into account the physical geometry of the cabinet—including openings between compartments, duct paths, and mounting surfaces. This produces more realistic and manufacturable wire routing results, helping designers validate cable feasibility earlier in the process. The updated routing engine also supports visual tools for verifying duct connections and identifying potential issues, speeding up troubleshooting and reducing the need for manual corrections during cabinet assembly.

Geometry-aware routing in E3.panel: Wire paths now follow cabinet cutouts, ducting, and surfaces—enabling realistic layouts and faster validation of routing feasibility.

Auto-rotation of components: Devices are now automatically aligned based on their mounting position, ensuring correct placement on sloped or angled surfaces

Smarter Cabinet Layout and Placement

The panel layout workflow has been significantly enhanced with smarter component behavior and more robust 2D/3D synchronization. Components can now auto-rotate to align with angled surfaces during placement, and STEP model imports offer more control, including the ability to skip or cancel individual files mid-import. Users can also resize multiple devices at once and manage complex assemblies with greater flexibility—reducing time spent on repetitive layout tasks and improving design accuracy across layout revisions.

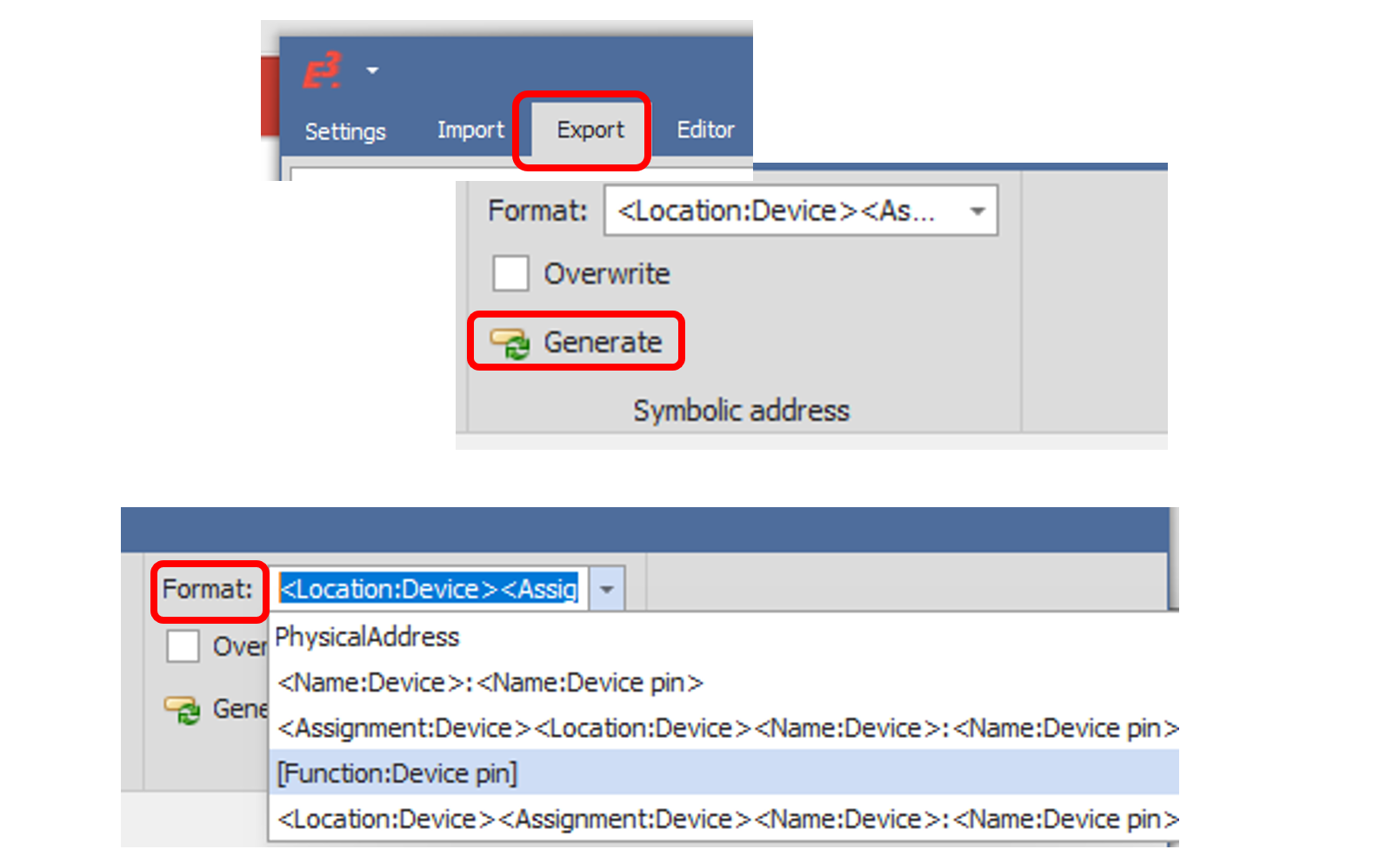

PLC Symbolic Address Generation

The E3.PLC Bridge now includes expanded support for leading PLC systems such as Omron, Rockwell, ABB, B&R, and Phoenix Contact. One of the key upgrades is automatic generation of symbolic addresses based on design logic and pre-configured rules. This reduces manual input, ensures synchronization between electrical design and control programming, and supports automation workflows where electrical and PLC teams need tight data integration for faster commissioning and reduced control-system errors.

E3.PLCBridge enhancements: New import/export interfaces support Omron, Rockwell, ABB, B&R, and Phoenix Contact. Symbolic addresses can be auto-generated from configuration rules for connected PLC devices.

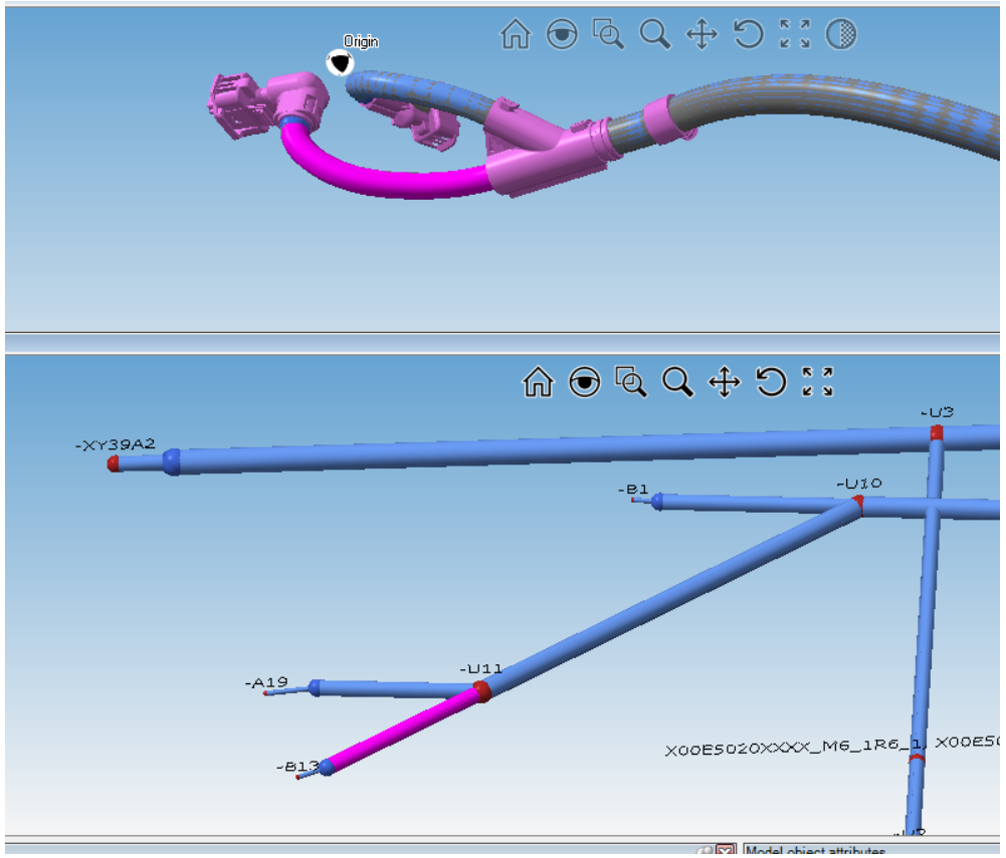

Automatic connector alignment, smarter harness flattening, and enriched metadata exchange for seamless cross-domain collaboration

Better ECAD-MCAD Integration

Cross-domain collaboration between electrical and mechanical design teams is enhanced through updates to E3.3D Transformer and the E3.3D Routing Bridge. Features such as automatic connector alignment, improved flattening of harness paths, and enriched metadata exchange reduce the effort required to coordinate 3D mechanical constraints with electrical intent. These updates help ensure that wire lengths, routes, and spatial constraints match between ECAD and MCAD environments—lowering the risk of integration issues during physical prototyping and final assembly.

Related Products and Resources

- Products

- Products

E3.series is a Windows-based, scalable, easy-to-learn system for the design of wiring and control systems, hydraulics and pneumatics. The out-of-the-box solution includes schematic (for circuit and fluid diagrams), cable (for advanced electrical and fluid design), panel (for cabinet and panel layout), and formboard (for 1:1 wiring harness manufacturing drawings). Integrated with MCAD, E3.series is a complete design engineering solution from concept through physical realization and manufacturing output.