- Blog

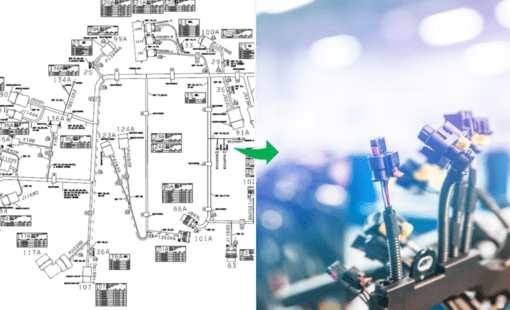

Assembling a wire harness is a complex process. Zuken, in concert with our customers and partners, is tirelessly working to simplify the harness manufacturing process. As a matter of fact, the common theme in most customer requirements is to reduce the gap between quoting and delivering the project. Seeing that, Zuken’s primary goal with Harness Builder for E3.series is to empower harness manufacturers to achieve their goals.

- Blog

An immature design or manufacturing process leads to excess complexity. Smart manufacturing options driven by intelligent design solutions provide a repeatable and efficient path to simplify manufacturing processes.

- Blog

We are closer than ever to a perfect design-to-manufacturing solution for simple and complex harnesses alike. In fact, the Harness Builder 2020 for E3.series release has more than 15 significant enhancements.

- Blog

The 2020 release of Harness Builder for E3.series is more than exciting, it is outright amazing. There are more than 15 major updates all across the toolset. New features include automation, reporting, and documentation options. Furthermore, the new downstream manufacturing, testing, and visualization connections are groundbreaking. I will cover our favorite 2020 updates in this two-part blog series.

- Blog

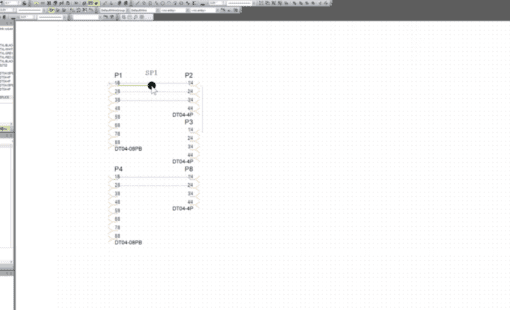

This video is a demonstration of how to import a wire to-from list in harness builder. This feature allows the user to define connection information such as signals, the to/from devices, cavity information, and the wires/cables in Excel to import into an E3.series project.

- Blog

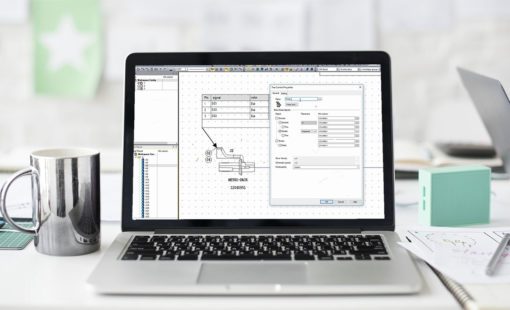

Using E3.series’ Component Table empowers users to make multiple changes to their library components faster and easier. It’s a very powerful and useful tool.

- Blog

The customization and workspace flexibility is one more way for E3.series to give the user what they need and want. All workspace customizations can be saved locally to provide a consistent user interface.

- Blog

There are numerous challenges faced by harness design and manufacturing teams across industries. In some, weight is the biggest challenge and in others, signal reliability is of utmost importance. The discussion today is less about the use of a harness and more about the information essential to ensuring your design and manufacturing processes are running efficiently.