The customization and workspace flexibility is one more way for E3.series to give the user what they need and want. All workspace customizations can be saved locally to provide a consistent user interface.

The required tabs/windows can be moved to a second screen (if available) to increase drawing space. The smart tab option activated in the customization menu helps move the windows into required locations with markers for easy access. The windows can be hidden to the side to automatically pop up when needed and stay out of the way at other times.

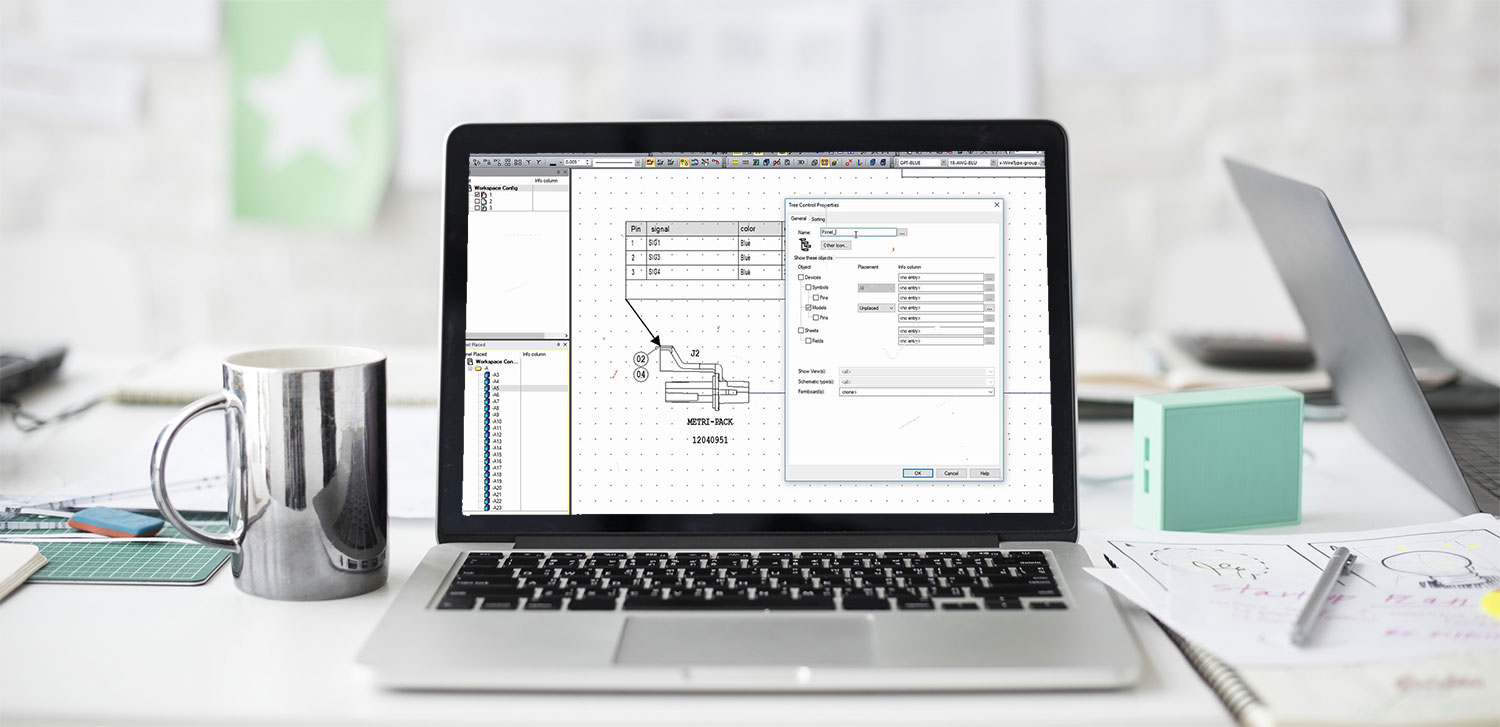

The project windows provide quick access to all the drawing sheets and devices added into the project. Panel parts can be accessed in a separate window subdivided into used and unused parts (this can be done for the regular device tab as well)

These customizations can go further with the options of customizing project windows and the items displayed in them. The View menu gives you access to several bulk data tables that can make light work of multiple changes. These tables are also customizable and provide access to all attributes in context.

It is best to have 2 workspaces in case there is ever a need to reset to a default workspace based on the design requirements.