All Roads Lead to Zuken

My passion for electronics started at a young age. From making simple circuits in grade school to fixing VCRs in high school, I held various technical jobs growing up. At one point, I also developed closed captioning equipment and worked on engine management systems. Around 2008, I began working for a company developing hybrid drivetrains for heavy-duty vehicles. One of my main tasks was documenting the outputs from engineering in Zuken’s E3.series tool suite. I was heavily involved in the process of implementing E3.series into their existing PLM and MCAD systems. I enjoyed that work, so when the opportunity to work for Zuken came around, I took it, and I haven’t looked back since!

Helping Customers as an Application Engineer

As an applications engineer, everything I do centers around making sure our customers get the most out of their product investments. This includes on-site or online training, supporting them by providing guidance on best practices for implementing E3.series in their work environment and solving any issues that arise. The most rewarding aspect of my job is helping customers find success by resolving their problems and achieving their end goals.

Each Day is a New Adventure

The role as an applications engineer is dynamic and multi-faceted. Each day is a new adventure. Besides taking care of customers’ day-to-day needs, I am always working on several long-term projects in the background. Right now, I’m developing technical content for the online community forums, staying on top of the latest E3.series features and tools, and creating deliverables for implementation projects.

In the two years I’ve worked at Zuken, I’ve been involved in two significant customer implementations and various smaller internal projects. My involvement has helped me become more knowledgeable and confident. That type of work is gratifying because my desire to problem solve helps customers and other applications engineers on my team.

Teamwork at its Best

I am fortunate to work with a helpful and supportive team. Though I’m still a relatively “new” member of the Zuken family, I feel comfortable asking questions or voicing my concerns to any of my colleagues. In my line of work, I enjoy working together with my fellow AEs, but also independently. Collaborating is a time for me to share ideas, but also to learn more from my coworkers.

Giving Back to the Community

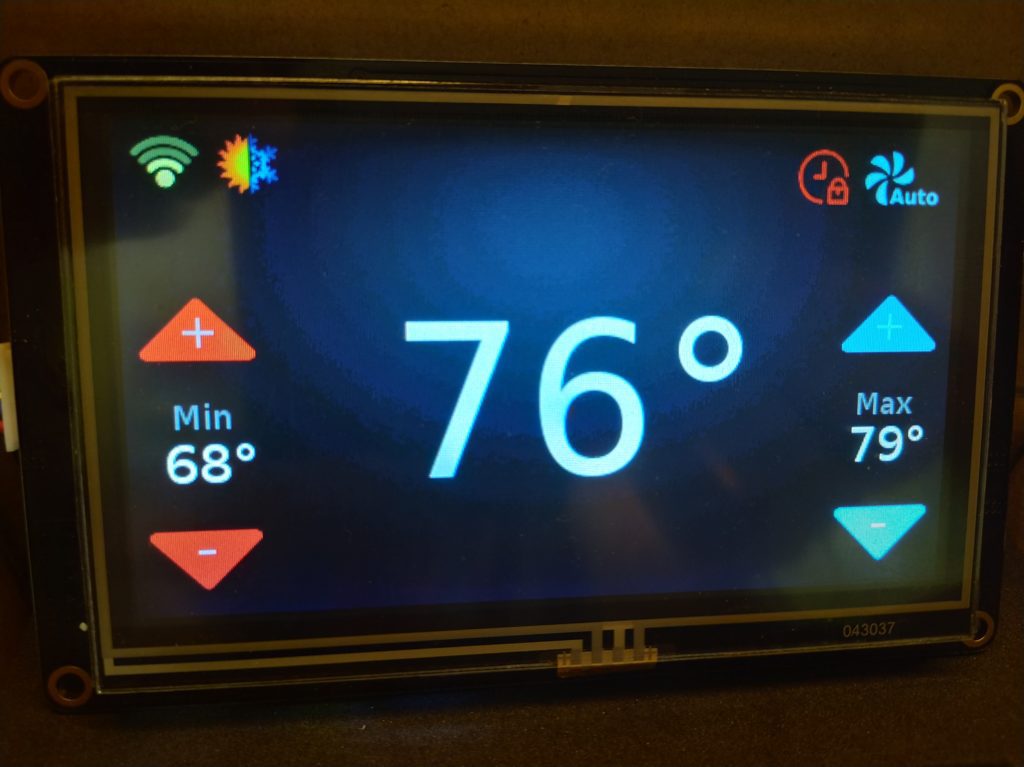

When I’m not working, I have many different hobbies and interests that keep me active and involved locally. Working on my electronic side projects is especially fun. Right now, I’m designing a smart thermostat and a Ham radio repeater controller. Volunteering with two non-profits helps me stay connected to the community. I am a board member and tower climber for the Arizona Repeater Association. In addition, I’m the State Digital Information Officer for the Arizona Rangers. I also dabble in music. While I don’t consider myself very good, I enjoy it as it provides some contrast to all of the technical things I do.

- Blog

What makes a winning Formula 1 car? Not brute force, but systems thinking. Find out how modern teams use MBSE to strike the right balance between aerodynamics, power, weight and heat, and transform complexity into faster lap times.

- Blog

AI in PCB design is increasingly seen as a game-changer, with some predicting it could soon replace entire layout teams—but this view risks overlooking both the current limits of AI and the critical expertise engineering demands. At DesignCon 2025, experts from emphasized that AI's real value lies in complementing human judgment, not replacing it. Read more on our blog.

- Blog

Explore the shift to Model-Based Development in mechatronic systems, enhancing efficiency and collaboration beyond traditional documentation.

- Blog

Traditional CAD software was once just a digital drafting tool, requiring manual updates and prone to inconsistencies. However, as electrical systems grow increasingly complex, intelligent CAD systems have transformed the design process. Learn more on our blog.