From Efficiency to Dynamic Capability in Product Development

by Yasuo Ueno, Senior Managing Executive Officer and Head of Business Strategy, Zuken, Inc

Manufacturing industries have made significant progress through digitalization and competitive dynamics, fostering product improvements and coexistence among firms. By integrating best practices and addressing cross-departmental needs, digital tools have enhanced efficiency and opened opportunities for new challenges in manufacturing.

In a stable market environment, competitive dynamics drive growth and “the rising tide lifts all boats”. This has been the case for many years with the European Automotive industry serving as a good example of an effective network of an effective ecosystem of competing OEMs and suppliers.

This dynamic led to a market characterized by relatively few large players in both segments. These structures developed in a somewhat stable market environment. In recent years, however, two disruptive changes – climate change and the departure from fossil fuels and new, fast-moving competitors mainly from China – have raised questions about how well this model is prepared to manage both challenges simultaneously.

How to Defend Premium Prices

Until recently, European manufacturers were able to justify price premiums through distinctive product characteristics: quality, energy efficiency, durability, and service. However, at least some of these attributes are about to erode: For many customers, Chinese products are just “good enough”, while offering a significant price advantage – driven in part by government support, particularly in the Automotive industry.

This development places European automotive and industrial manufacturers in a potentially difficult position and calls for nothing less than a survival strategy: How can we support our customers in addressing these challenges? How can we jointly develop suitable strategies and implement corresponding solutions together? How can Europe draw lessons from a similar transition in the Japanese economy?

Yasuo Ueno: A Balanced Approach to Driving Innovation and Efficiency

Zuken’s Head of Strategy, Yasuo Ueno, will share his insights into digital transformation in a series of articles.

Yasuo Ueno is Senior Managing Executive Officer and Head of Business Strategy at Zuken, Inc. He joined Zuken in 1985 in a sales role and established the company’s PLM business in 1995. Today, his primary focus is the development of Zuken’s digital transformation (DX) business, built on CAD/PLM and model-based systems engineering (MBSE).

He is also a member of the Digital MONOZUKURI Research Group led by Professor Takahiro Fujimoto.

Let us first take a brief look at the situation in Japan: Japanese manufacturers, particularly in consumer electronics, had successfully developed global markets up to the year 2000. At that time, the industry was large and robust, comparable in scale and strength to today’s Japanese automotive industry.

The Japanese consumer electronics market then comprised approximately 100 competing corporations. Despite intense competition, most remained profitable through a strong focus on efficiency, cost reduction, broad product portfolios, and consistently competitive product quality. CAD and PLM played a significant role in intensifying this competition, enabling a form of “co-evolution” among companies. These tools supported a rapid race to produce successive derivative variations in design, form factors, colors, functions, and configurations.

With the market success of the iPhone, however, it became clear that consumers were no longer seeking endless variations of similar products, but rather new and compelling user experiences. As digitalization progressed, Asian countries increasingly came to dominate the consumer electronics industry. Modular product architectures made it easier to generate variations quickly, further accelerating this shift. Today, little remains of Japan’s once-thriving digital consumer electronics sector – often cited when discussing the decline of Japanese manufacturing.

However, according to Professor Takahiro Fujimoto, the data tells a different story. Around 1990, when Japanese manufacturing was widely regarded as invincible, exports of industrial products stood at approximately 270 billion yen. By 2022, this figure had exceeded 600 billion yen, more than doubling over the period. During the same time, the manufacturing workforce declined from roughly 15 million to 10 million employees over the past 30 years. Yet total real value added continued to grow steadily, rising from 530 billion yen 30 years ago to approximately 800 billion yen today.

Japan might be best known for its automotive industry, but it is also home to several other high-tech sectors, including medical technology, robotics, semiconductor equipment and industrial infrastructure. These industries continue to perform strongly in internatinal markets. The strategic direction of Japanese manufacturers is clearly oriented toward further growth in these high-value domains.

Moreover, as the wage gap with China continues to narrow, Professor Fujimoto argues that Japanese manufacturers are increasingly well positioned to compete effectively with Chinese counterparts by continuously improving productivity and quality.

How Japan’s Ministry of Economy Is Reframing Corporate Competitiveness

Japan’s Ministry of Economy, Trade and Industry (METI) has emphasized that companies must what it terms ‘dynamic capability’. According to METI, such capabilities are essential because an exclusive focus on efficiency can reduce sensitivity to market shifts, ultimately leading to missed opportunities and lost business.

METI has drawn lessons from the profound transformations of the electronics industry and is keen to ensure that Japan’s high-tech sectors – including automotive manufacturing – retain their competitive strength. To enable genuine innovation, companies must be able to capture market trends in an agile and flexible manner, which in turn requires a deliberate restructuring of organizational capabilities.

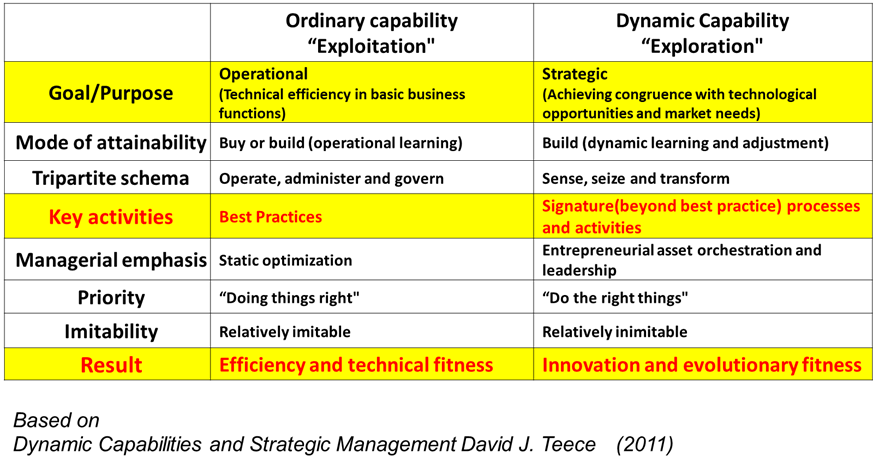

In this context, book ’Dynamic Capability and Strategic Management’ became essential reading for Japanese executives, alongside ‘Lead and Disrupt: How to Solve the Innovator’s Dilemma‘. To illustrate this distinction, we introduce a key chart that compares dynamic capabilities with ordinary capabilities.

How Engineering IT Supports Both Operational Excellence and Dynamic Capability

What are the ‘organizational capabilities’, and what is our contribution to them? According to research presented in ‘Dynamic Capabilities and Strategic Management’, companies require both dynamic capabilities and ordinary capabilities as core organizational capabilities. The research further emphasizes that balancing existing business strengths with new forms of innovation is essential for sustainable corporate success. With this in mind, let us briefly return to history and examine how Engineering IT has supported both capability types.

We are confident that our engineering IT technologies – CAD/CAE and PLM – have significantly increased our customers’ efficiency and technical fitness by embedding best practices into engineering processes. This has delivered clear economic benefits while freeing up valuable human resources. In this way, CAD/CAE and PLM have made a substantial contribution to customer’s ordinally capabilities. This aligns with the observation made earlier in this article: conventional digital tools have primarily supported organizational capability to correspond to mainly existing challenges in manufacturing.

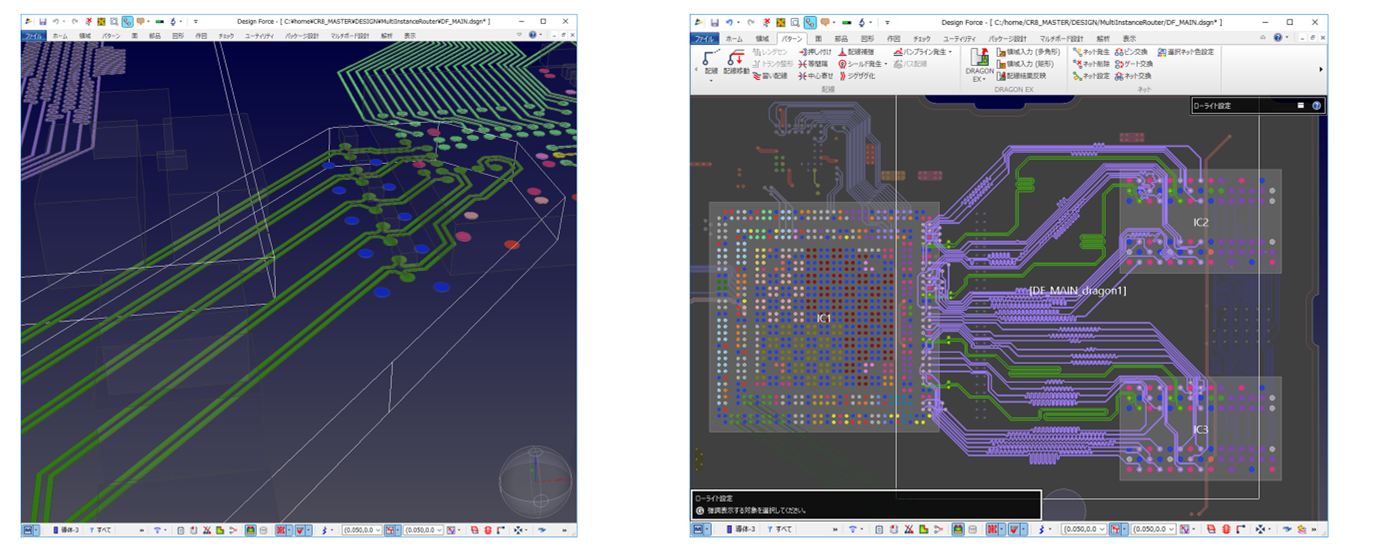

Implementing best practices consistently across processes is critical to making optimal use of limited resources. Zuken’s nearly 50-year history has been largely dedicated to this mission. To illustrate this contribution, we now introduce a set of visuals that highlight how best practices are embedded in our tools.

-

Dragon Router in CR-8000

Left: Differential routing performed according to specified wiring constraints, with explicit consideration of differential pairs (routing time: several seconds).

Right: Automatic equal-length meander routing. Both left- and right-side routing are completed in several seconds to a few minutes. -

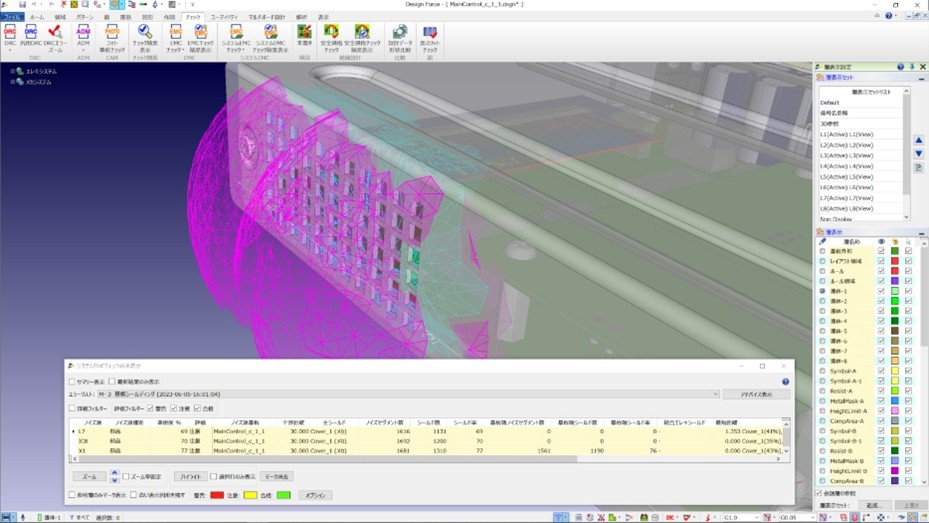

Reducing EMC Issues Early with 3D System-Level Verification

The 3D EMC Adviser enables EMC verification of electrical and mechanical components as well as PCB-to-PCB interactions within 3D models

-

3D Cable Routing and Movement Analysis

XVL-WR integrated with IPS (fleXstructures) and driven by E3 connectivity enables 3D cable routing and movement analysis, reducing late-stage rework -

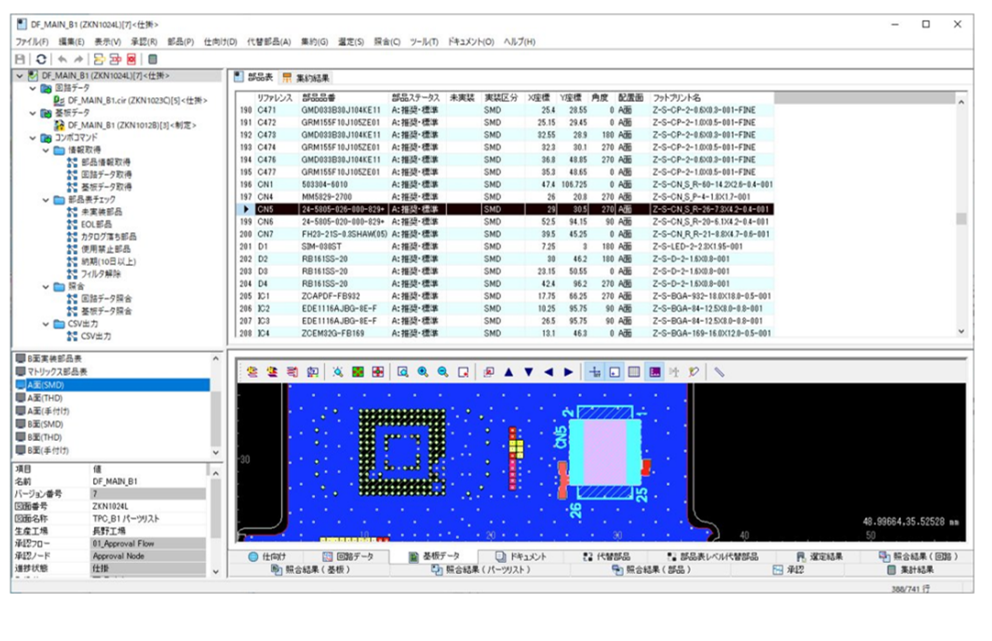

Automated Component Selection and BOM Generation with Variant Support

Using DS-CR, companies can automatically select suitable components and generate bills of materials for purchasing and manufacturing, resulting in significant efficiency gains through standardized digital best practices.

However, in today’s market environment, efficiency alone is no longer sufficient to drive innovation. Organizations must be able to recognize emerging changes, respond to them effectively, and adapt their structures and processes accordingly. This ability constitutes the dynamic capability that must be developed and embedded.

Having clarified what we mean by innovation, let us now examine how engineering IT can contribute. Innovation can be understood as the creation of new combinations: it emerges from recombining existing knowledge and resources rather than from entirely new inventions. In today’s environment, this requires greater agility and the ability to manage increased complexity. It also underscores the importance of leveraging and digitizing company assets in order to enable new and valuable recombinations.

MBSE: Building Dynamic Capabilities Through Engineering Knowledge

How can IT contribute to the development of dynamic capabilities? A key lever lies in the digitization of engineering knowledge, design assets, and development processes through model-based systems engineering (MBSE). We view this MBSE environment as a company-specific engineering knowledge base: a structured repository that captures how products are designed, validated, and evolved over time.

In similar product design cases, this knowledge base enables systematic reuse, earlier and more reliable validation and verification, and consistent linkage from requirements to detailed design. Because this knowledge is digitized and model-based, it can be applied in a flexible and agile manner across projects, allowing organizations to respond more effectively to changing requirements and market conditions.

Although MBSE methods and tools originated in the aerospace and defense sectors, Zuken recognized early on that the concepts are equally applicable to manufacturing industries beyond A&D – mainly in B2B domains such as automotive, medical technology, and industrial equipment. Consequently, Zuken acquired the U.S. MBSE company Vitech in 2019. This strategic direction has since been validated by the market, with more than 30 companies currently engaged in proof-of-concept initiatives. We consider MBSE a major enabler for companies seeking to build and sustain dynamic capabilities over time.

Competitiveness Requires More Than Efficiency

In today’s market environment, efficiency alone is no longer enough. Sustained competitiveness depends on developing dynamic capabilities – the ability to sense change, seize opportunities, and transform with agility. By combining operational excellence with innovation, companies can stay resilient and achieve sustainable growth.

In our next article, we will explore this concept further: How does “dynamic capability” reflect the challenges European manufacturers are facing? And what should be the true focus of Industry 4.0 in Europe – developing these capabilities, or simply increasing efficiency through digitalization?