New Products

- Products

- Products

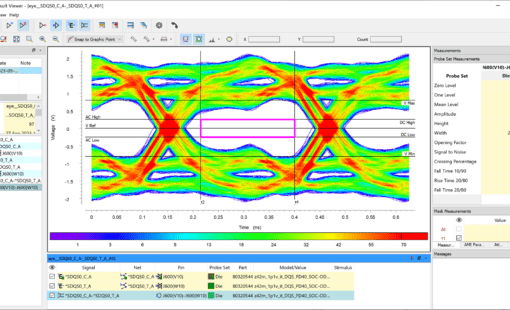

Design Force SI Advance combines a comprehensive range of new functionalities to enhance your signal integrity analysis capabilities.

- Products

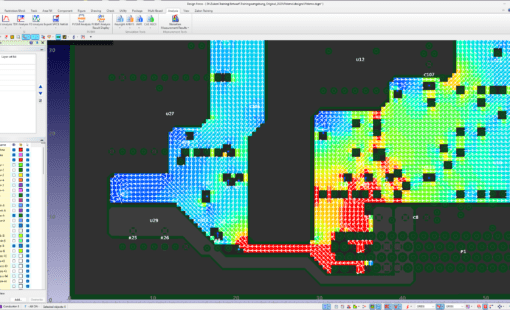

Design Force PI/EMI Advance provides powerful capabilities for PCB-level EMI and Power Supply System Analysis. It offers a fast estimation of worst-case electromagnetic emissions.

- Products

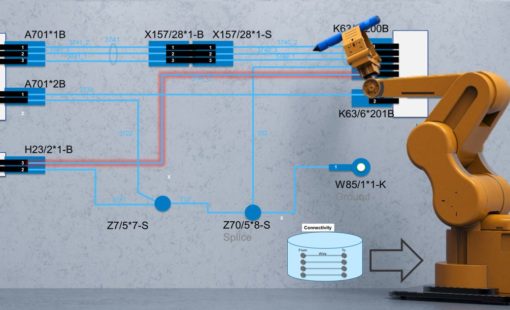

E3.ConnectivityBrowser - Automatically visualize connection information as circuit diagram representations

- Products

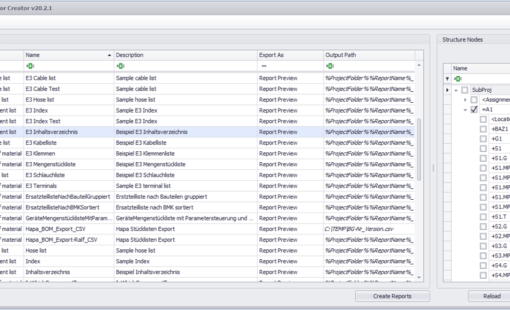

The E3.ReportGenerator is a free tool for creating customised reports from E3.series projects in a few simple steps. These reports can be configured according to various parameters and exported in various formats. The tool requires no licence and can be launched directly from within E3.series.

- Products

GENESYS is an integrated model-based systems engineering software toolset that covers all four domains of systems engineering — requirements, behaviour, architecture, and verification and validation.

New Releases

- Products

E3.series Release 2023 - an overview of the most important new features

- Products

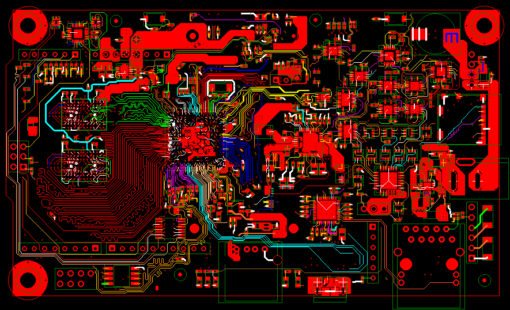

CR-8000 Release 2023 includes enhancements to support design efficiency and analysis, enabling users to tackle the challenges of high-density, high-speed PCB designs. A specific focus was given to reorganizing and extending CR-8000's comprehensive range of signal integrity, power integrity, and EMC analysis tools, now packaged in the configurations of CR-8000 Design Force Analysis Advance.

- Press Release

GENESYS 2023 includes improved capabilities for storing, organizing, and managing views.