Zuken Helps Designers Get Better Product Enclosure Fit with True 3D Component Shapes in CR-8000 Design Force

15 September 2015 – Munich, Germany and Westford, MA, USA – Zuken helps product designers meet the challenges of today’s ever-smaller and complex enclosures, with 3D clearance analysis using true component shapes. True 3D checks of multi-board designs can be carried out against all aspects of a product, including the enclosure. This latest version of Zuken’s CR-8000 single and multi-board design solution also includes improved accuracy in layer configuration design work through transfer of layer configuration data between CR-8000 Design Force and Polar Instruments Speedstack.

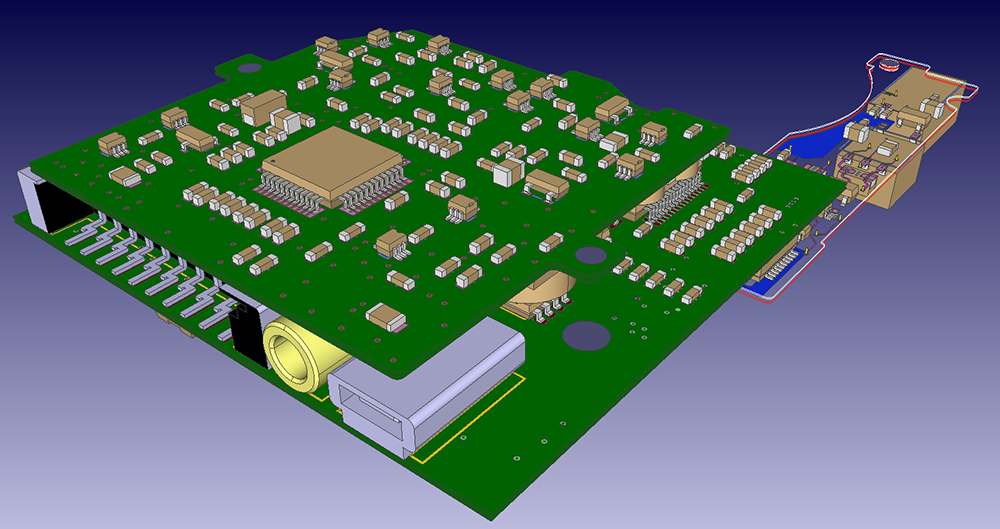

Zuken’s CR-8000 is the industry’s only next-generation, product-centric design solution for creating complex product designs. CR-8000 Design Force enables design teams to easily create any design from quick prototype boards to complex, multi-board systems using a single tool.

CR-8000 is leading the way in product-centric design and the 2015.1 release will strengthen our customers’ competitive positions with the addition of true 3D product-centric capabilities.

“Successful companies build more competitive products faster and with lower risk. Next generation products will require those same companies to shift from PCB-centric to product-centric design practices to remain competitive. CR-8000 is leading the way in product-centric design and the 2015.1 release will strengthen our customers’ competitive positions with the addition of true 3D product-centric capabilities,” says Bob Potock, Vice President of Marketing, Zuken Americas.

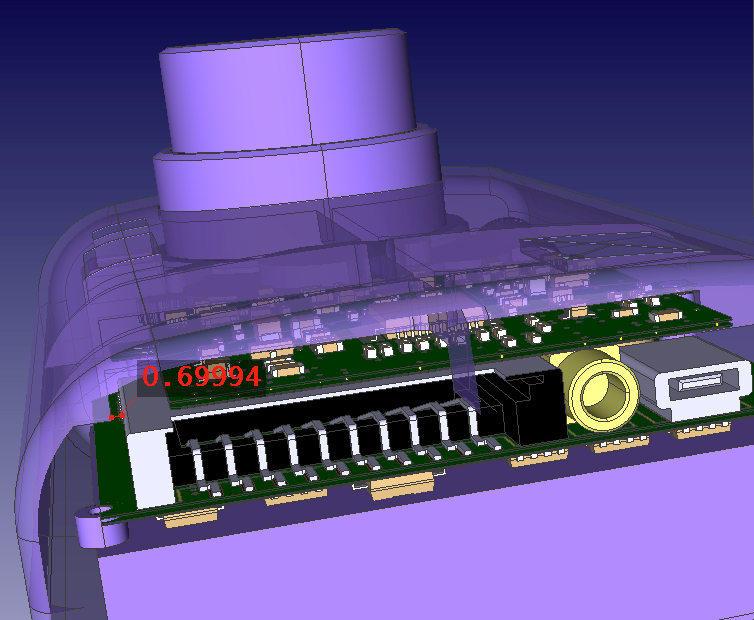

Clearance analysis to the true component shape

As manufacturers push to fit boards in ever-smaller spaces, enclosures become more complex and achieving a good product fit gets harder. It is estimated that up to 50% of prototypes need to be reworked at the manufacturing stage because of a fit problem creating significant project risk in terms of cost and time for product designers.

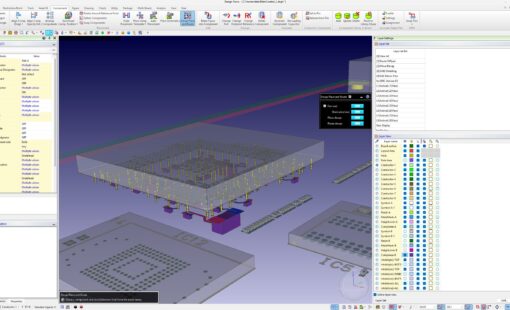

To help meet this challenge, CR-8000 Design Force now allows users to perform even more accurate 3D checks by using a true 3D component model with a precisely-matched 3D shape, rather than simply using a shape defined by a boundary box. Accurate shape parts can be used for collision checks and 3D clearance checks. This ability to check the enclosure early and continuously in the design process supports better collaboration between the electrical and mechanical design teams, eliminating the silo effect and reducing time to market and design iterations.

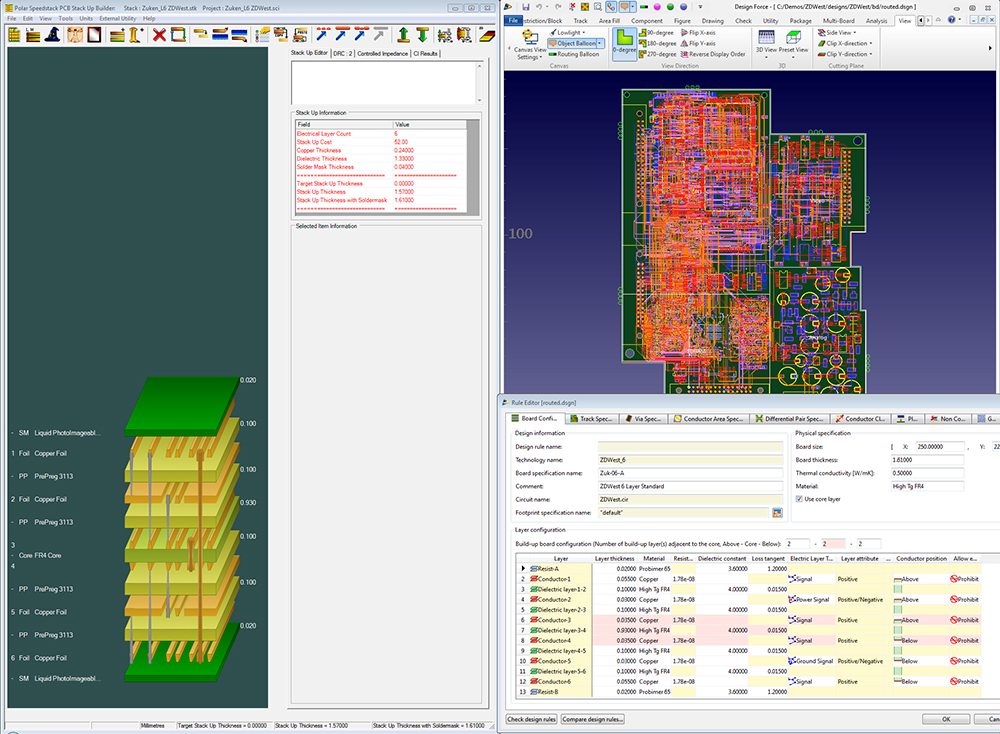

Detail board stackup design and specification

Layer configuration data can now be transferred between CR-8000 Design Force and Polar Instruments Speedstack, bringing the manufacturing and PCB design stages closer together. This ensures that the most accurate and up-to-date information from material manufacturers and PCB manufacturers is being used, removing the need to re-input stackup data thus saving time and improving quality.

User productivity and efficiency enhancements

- A number of productivity and user operability enhancements are available in CR-8000 2015.1, including:

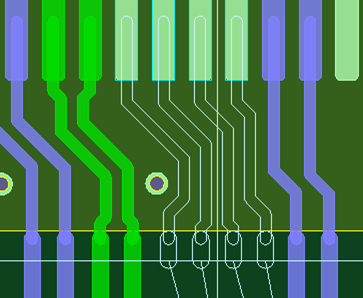

- Design edit function enhancements – It is now easy to create line shapes considering the production yield ratio and signal quality.

- Track width changes – When routing with the track/route differential pair/bundle route command, the track width now changes automatically on the boundary of a rule area.

- New export formats for outputting waveforms in the waveform viewer, improving efficiency in documenting and reporting signal results for engineering information and review.