How companies manage their design data and processes

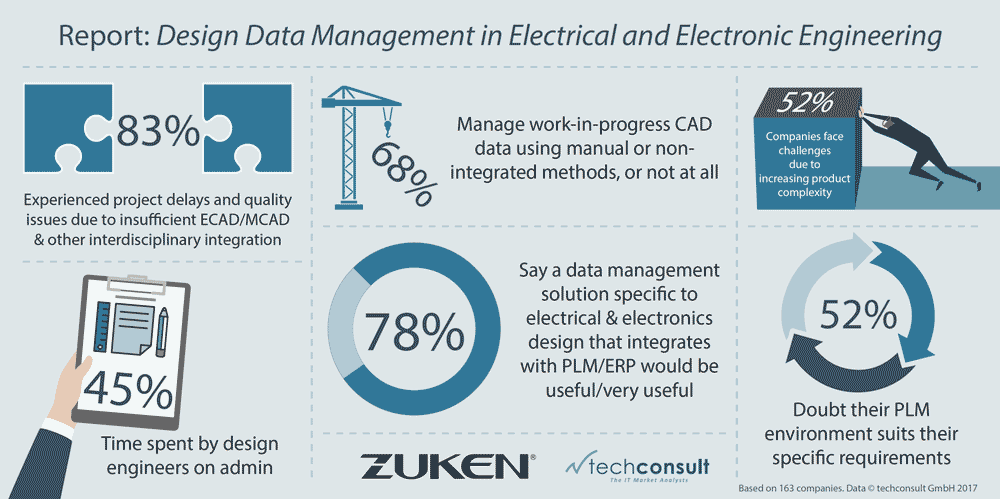

12 October, 2017 – techconsult GmbH, Kassel, Germany – Electrical and electronic engineering product designers spend an economically unsustainable 45% of their time on administrative activities, according to the report “Design Data Management in Electrical and Electronic Engineering”, produced by techconsult.

One of the main reasons is insufficient management of design data and component libraries. However PLM systems are not seen as the ultimate solution for managing these issues and winning back time, with 52% of those using PLM systems to manage electrical and electronic engineering data rating their systems as being suitable, but with limitations. When questioned further, 77% of respondents did not believe that a PLM system would help them work more productively.

More than 50% of electrical and electronic engineering product designers say PLM systems have limited suitability for their specific requirements

- 52% survey engineers have doubts about the suitability of current PLM environments for their specific requirements.

- 39% need to better coordinate mechanical and electronic engineering activities.

- 52% cited growing product complexity as their greatest challenge.

- 45% see a need to implement end-to-end digital processes from sales to engineering and production.

Winning back time to deal with increased design challenges

Technologically advanced industries such as mechanical and plant engineering, transportation (including aerospace), electrical engineering and electronics are facing a highly competitive global marketplace characterized by shorter product lifecycles, growing product complexity and the digitization of business and manufacturing processes.

In many design departments administration and documentation activities, which arise during engineering processes, take far too long. Indeed, engineers were found to spend 45% of their time, on average, on supporting activities – taking away from them time they could be spending on design and innovation.

“This distribution of engineers’ time needs to improve for companies to continue to be successful; for optimized development processes leading to increased productivity. In every design project a huge amount of data is generated and, with growing product complexity, this will only increase. So design engineers need access to solutions that allow them to manage large volumes of data and retrieve up-to-date information when it is needed,” said Verena Bunk, Senior Analyst at techconsult.

Engineering data management solutions

Solutions for effective engineering data management could support engineers in their day-to-day work by making processes more effective and allowing them to focus more on their core activities. When asked whether PLM systems were likely to help with this, 77% of respondents did not expect to work more productively using a PLM system. Engineers perceived PLM systems as complex and requiring duplicate data entry, and there is also the expectation that the specific requirements of engineers of all disciplines would not be adequately considered. Indeed, 62% expected additional overheads due to the manual data entry required to maintain different systems.

Industry challenged by growing product complexity

Respondents, who were primarily engineering team leaders, R&D directors, product managers and project managers, cited product complexity as their greatest challenge in electrical and electronic engineering (52%), followed by the need to increase design productivity (46%) and increase design reuse (45%). Almost half, 45%, see a need to implement end-to-end digital processes from sales to engineering and production, while 39% need to better coordinate their mechanical and electronic engineering activities.

However, the majority of companies do not have a dedicated solution in place to support and control engineering activities. The result is a growing non-productive overhead for engineers, taking away valuable time for core engineering activities. These factors combine to create substantial economic issues.

About the Survey

The survey: “Design Data Management in Electrical and Electronic Product Design” was designed and conducted by techconsult GmbH on behalf of Zuken GmbH. 163 leading manufacturing companies in Germany, Austria and Switzerland were surveyed about the design of their electrical and electronic engineering assemblies and systems. The sample covered technology-intensive industries such as mechanical and plant engineering, vehicle construction including the aerospace industry, electrical engineering and electronics. Only companies of all sizes with an annual turnover of 80 million euro and more were considered.

Author:

Verena Bunk, Senior Analyst

techconsult GmbH, Kassel

Tel.: +49-561 / 8109-141

verena.bunk@techconsult.de

www.techconsult.de

** Ends **

About techconsult GmbH

Research and analyst firm techconsult has been the partner for suppliers and consumers of digital technologies and services for 25 years. Conducting analyses at businesses provides an insight into their problems and their future visions regarding the use of information technologies. More than 20,000 interviews conducted with business and IT decision makers each year provide an accurate impression. Additionally, techconsult continuously screens suppliers’ products and services to provide strategic and implementational consulting to the IT industry and business users. For a number of years techconsult has been providing specialized assessment tools to business and IT decision-makers for the identification of problem areas and conducting positioning analysis. techconsult GmbH is headed by managing partner and founder Peter Burghardt with offices located in Kassel and Munich. The company is part of the Heise Group.