Zuken Addresses Complexity Challenge with E3.series 2018

24 July 2018 – Munich, Germany and Westford, MA, USA – The latest release of Zuken’s electrical and fluid engineering solution, E3.series, addresses the challenge of growing complexity within today’s products and processes. Key enhancements lie in the areas of topology planning, modularity support and variant handling, which are designed to support the requirements of manufacturing companies using modular product design to control complexity.

Other highlights include:

- Extended access to detailed information in electrical and fluid diagrams, cable plans and formboard drawings to increase productivity.

- Further automation of the autorouting functionality for cabinet layout in E3.panel.

- Polish language support.

Joachim Frank, E3.series Business Manager, says: “Most of the enhancements in E3.series 2018 have been developed in close collaboration with our global customers; in many cases to support their efficiency improvement programs. Zuken extended the modularity and variant management functions empowering the configuration management capabilities we recently introduced with our engineering data management environment DS-E3.”

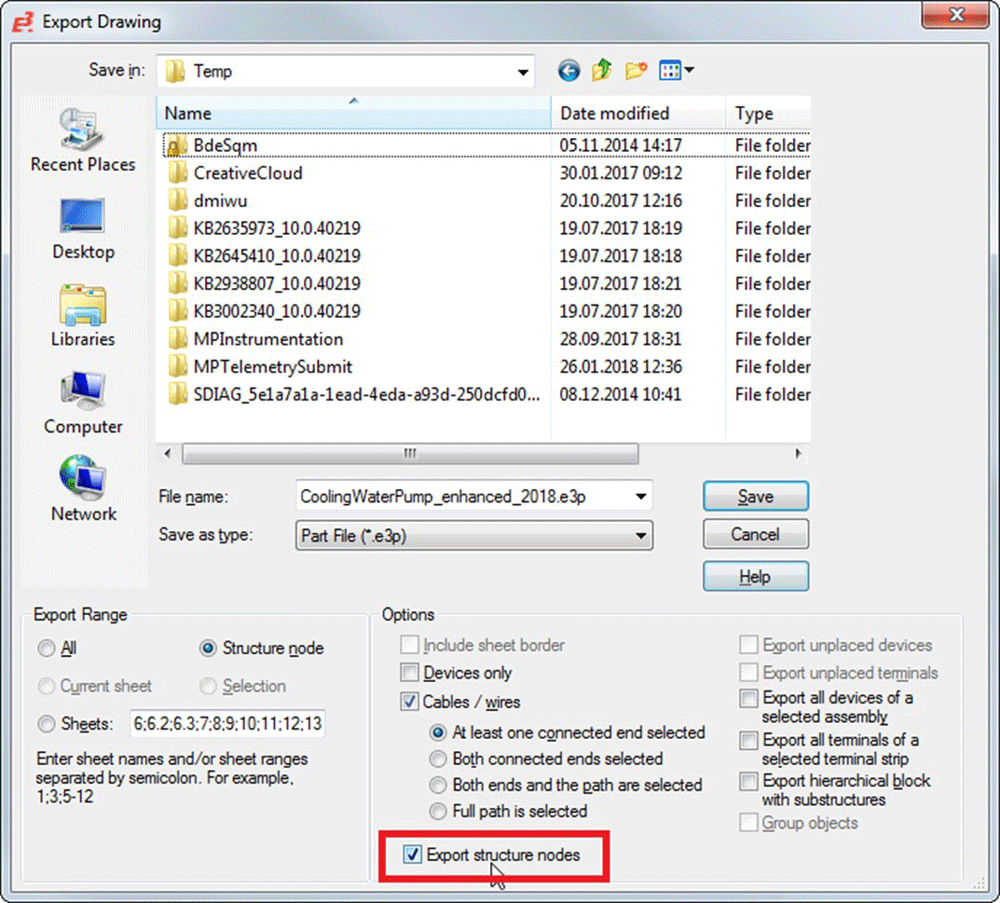

Modular project support

E3.series has long offered design reuse support. Proven sub-circuits and fluid plans can be stored in a library and loaded into new designs with the aid of powerful auto-connect functionality. With E3.series 2018, sub-circuits can be imported and exported, together with their node assignments and attributes. Attributes of all related nodes can be exported automatically, maintaining their inheritance properties, reducing manual effort, and creating the prerequisites to automatically generate projects with configuration tools.

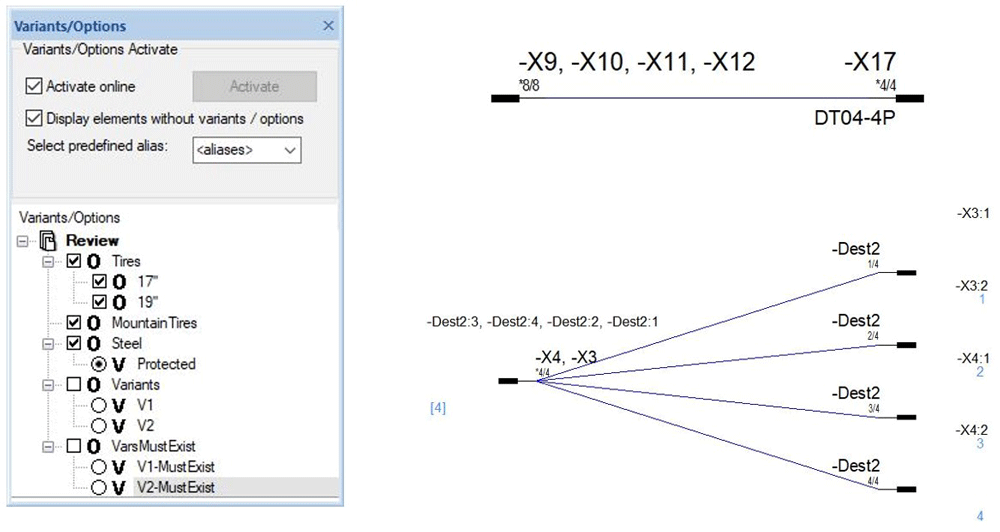

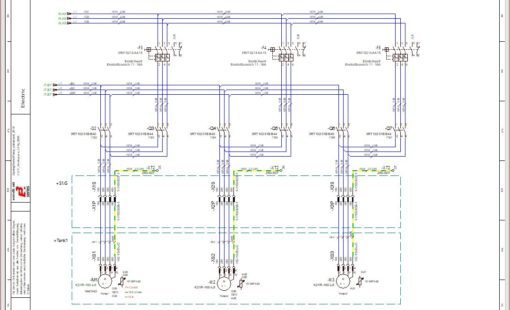

Efficient variant handling

The management of circuit variants and options has been extended with the ability to display multiple connectors with different variants and options in a single symbol. E3.series allows users to select individual configurations from 150% designs in the feature tree, from which individual configurations can be filtered. The related text, connection targets, and wires placed on the connection line are displayed automatically, as variants or options are activated in the feature tree.

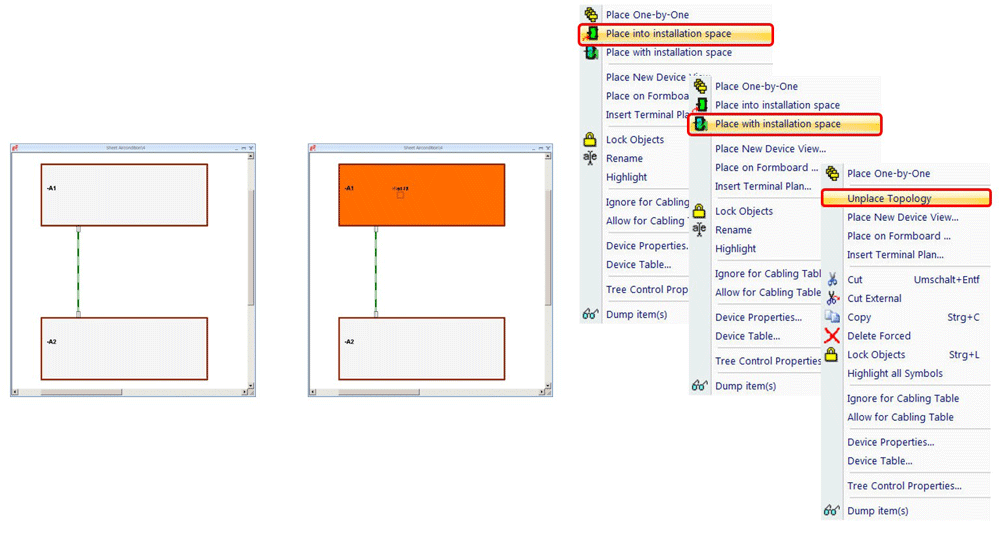

Topology planning

With the growing adoption of modular product architectures, upfront planning and evaluation of device placement is assuming growing importance. Topology planning in E3.series has been enhanced to support loading and connecting of installation spaces to open connections. Unplaced components can be placed either into an installation space or together with an installation space.

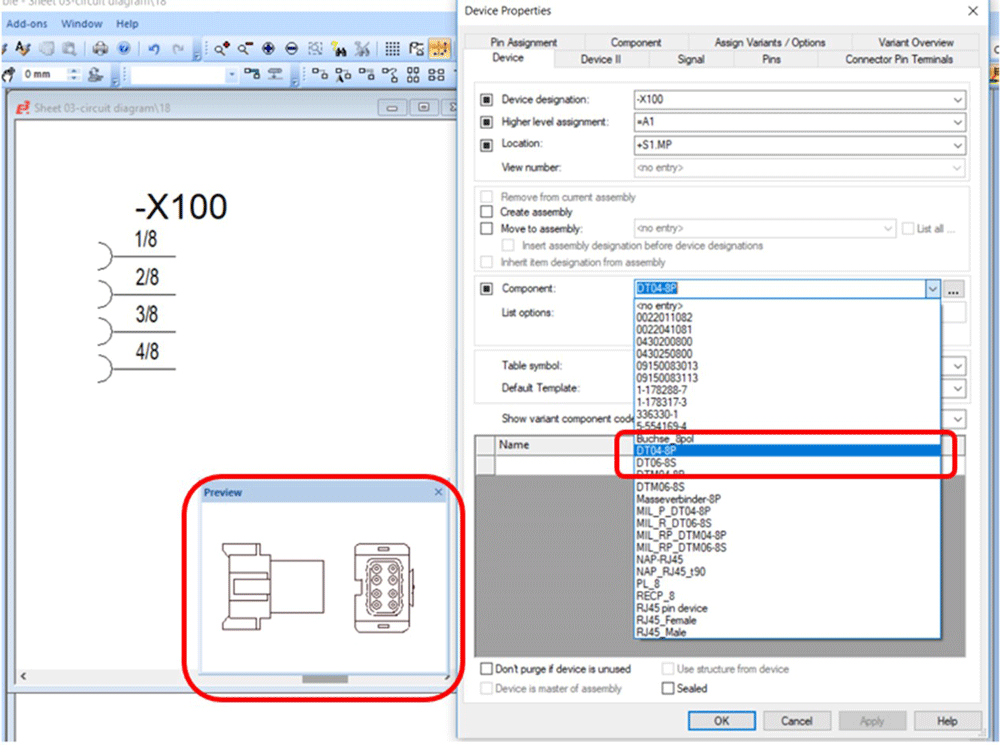

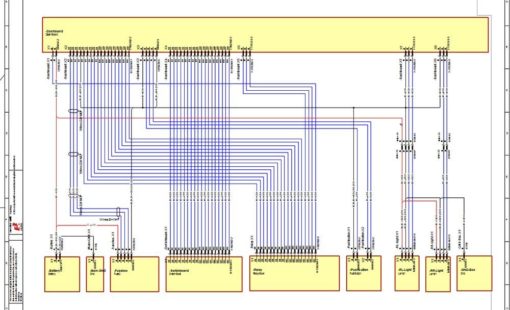

Extended access to device and connection properties

Access to device properties and connection details in schematic, cable plan and formboard drawings has been enhanced to support the requirements of advanced users. A preview symbol is now displayed automatically when selecting a component in the device tree. Device table configurations can be stored as templates, so that the appropriate information for different process steps can be provided. User defined representations, such as corrugated tubes on curved connections, can be generated in the fonts library and applied to all graphical elements.

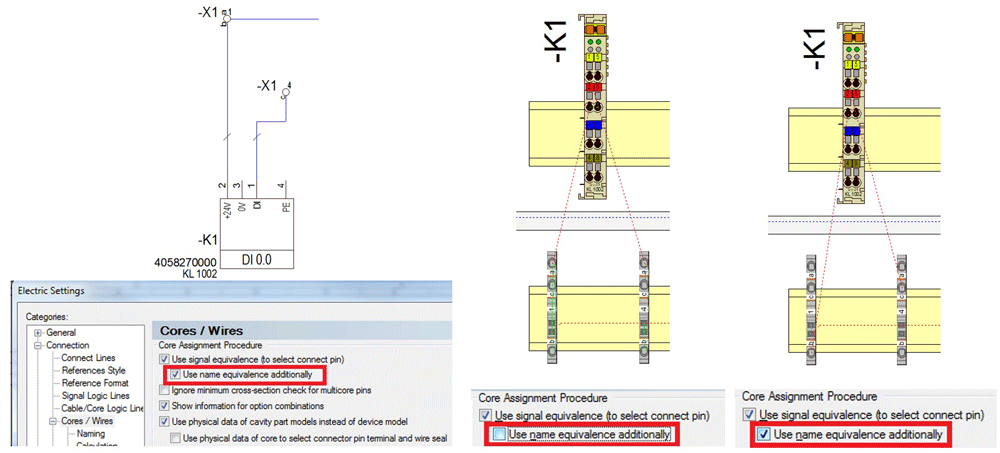

Ease-of-use

Ease-of-use has been further enhanced by additional sorting and selecting capabilities in E3.schematic. Connections can now be sorted by assignment or location only, in addition to the existing sorting option by both assignment and location. Conductors in dynamic cable and wires can be renamed in alphabetical order, and selected object types (e.g. text) can be excluded or filtered from connections. The automatic routing of cables in E3.panel now also considers name equivalents in addition to equivalent symbols, so that wires can be connected precisely to their intended terminal.

Related products

- Products

- Products

E3.cable extends the functionality of E3.schematic enabling individual conductors to be combined together in the design to form cables and harnesses.

- Products

E3.series is a true concurrent electrical engineering environment supporting advanced requirements for electrical documentation, cabinet and wire harness design and manufacturing outputs.