System design engineers are under constant pressure to reduce time, and costs and operate in a right-first-time environment. The most common tasks that an engineer performs, can sometimes be the most time-consuming, cumbersome, and error-prone processes.

Using the same component, over and over again in different systems or products is one of the many common tasks – and it makes perfect sense because it contributes to reducing parts inventory cost. But this seemingly simple action is an area that can consume an engineer’s time and add costs of incorrect parts and lost time in errors in the manufacturing process.

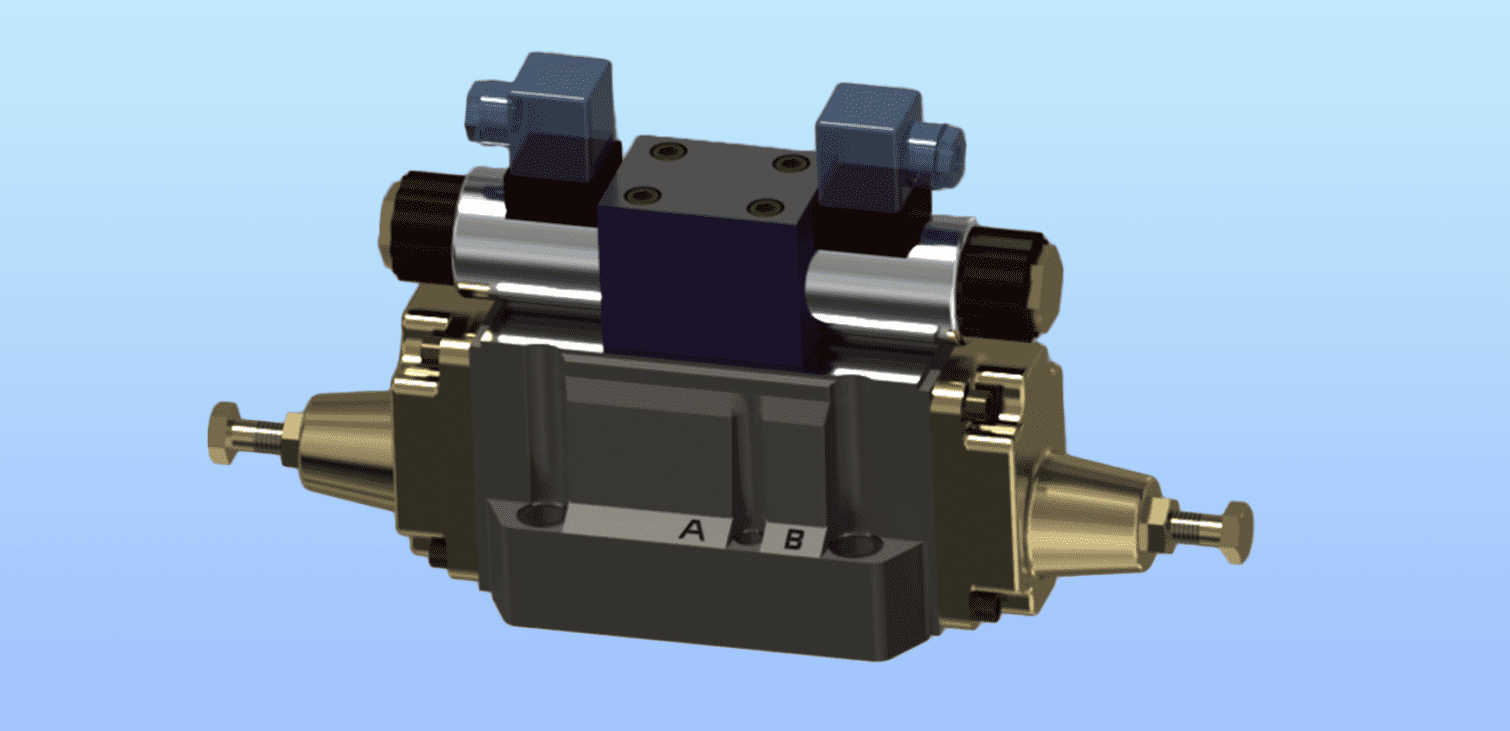

For example, inserting a solenoid into a circuit may seem a trivial task but there are many, many things to address.

- What connector to use?

- Should the connector be waterproof?

- Are there seals for the connector?

- What size wire seal should be used?

- Is there cavity blanking seals required?

- What terminals should be used?

- What size terminal should be used?

- What material of terminal should be used?

- Is there a terminal position assurance required?

- What additional parts are / can be used?

All these can come in a multitude of configurations requiring adjustments depending on location, requirements, etc. Incorrectly specifying one of these items can cause manufacturing, production, and service issues.

Imagine inserting a solenoid specified for a specific function. If one of the many parameters is overlooked, it may turn out that the required connector and terminals don’t match the wire size specified in your design. Should this error be overlooked and the design progresses to the wiring harness stage in production, major problems can occur where no connector and terminal are available for the required wire size. Weeks and months may have passed, and this issue could result in prolonged delays to a project as alternatives are found, and lead time to components increases.

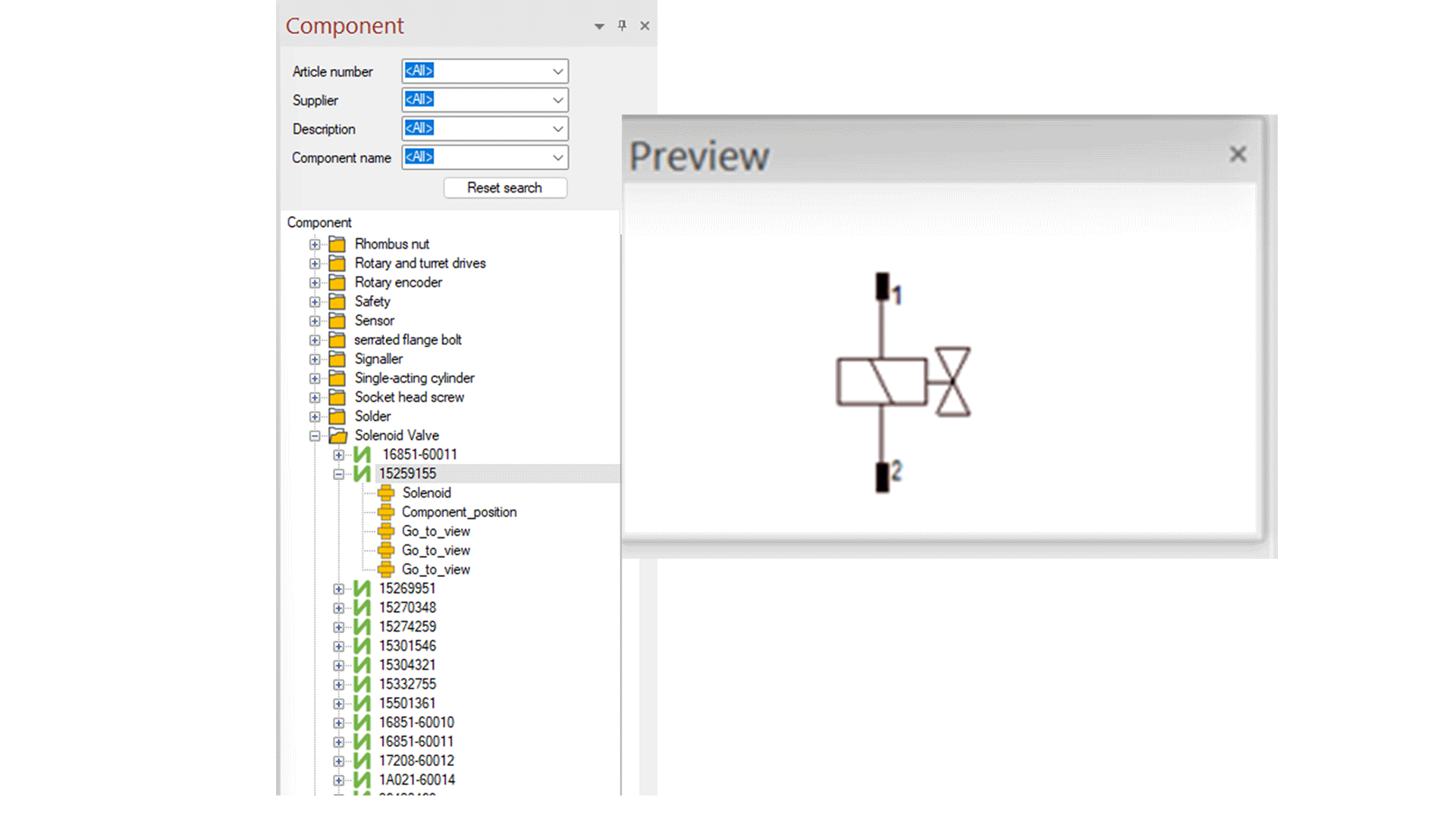

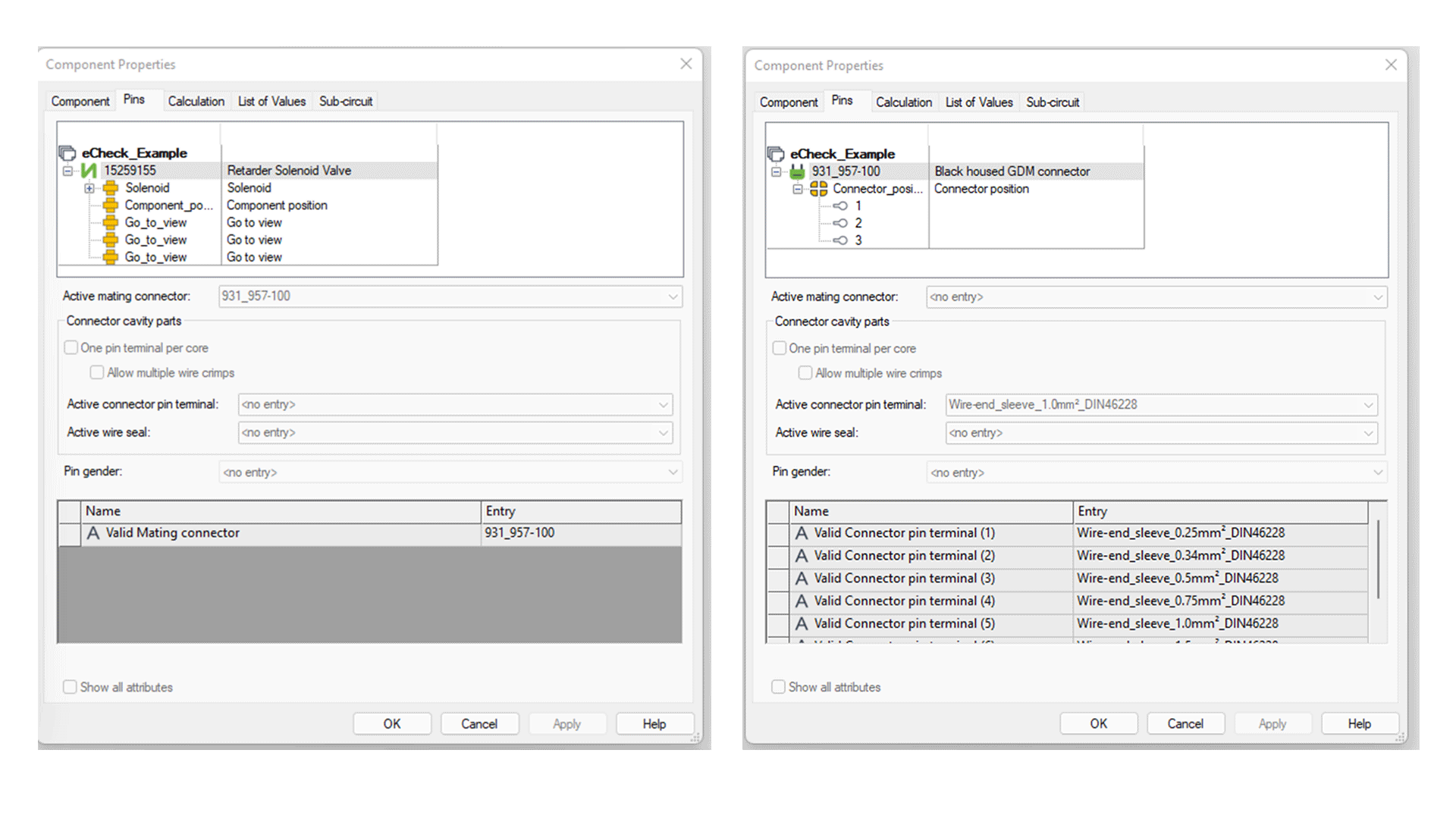

E3.series can resolve these potential issues with its intelligent component-based parts library and optional Component Cloud for E3.series. The database ensures only real and correct parts are used and helps drive the design with automatic part selections. Simply using drag and drop, a component can be inserted into a project, directly from the database.

All associated parts such as connectors, wire sizes, and seals are also brought into the project instantly. When a wire is then connected to the component, the assigned connector is attached and along with it, the required seals, cavity plugs, and terminal position assurance parts are automatically added. Terminals are assigned with their appropriate seals. If a wire is attempted to be connected, the user is informed that this isn’t possible due to the non-availability of the terminal for that wire size. All this functionality happens in the blink of an eye!

The database is available as a standalone PC-based structure, a server-based structure so multiple users can use the same data or a cloud-based structure. The collaboration options start with the library database shared across users. The database-driven collaboration option in E3.series.series helps multiple users across different departments and sites to work together on the same project with live updates to ensure consistency with minimal overheads.

Learn how the Component Cloud can be integrated into E3.series in our on-demand webinar

- Webinar

Zuken partner ECAD-PORT presents services around the Component Cloud for E3.series, which are designed to make building and maintaining E3.series libraries easier and more economical.

- Products

The Zuken Component Cloud for E3.series provides online access to free, validated, high-quality electrical component data to users of Zuken’s E3.series electrical design tools.