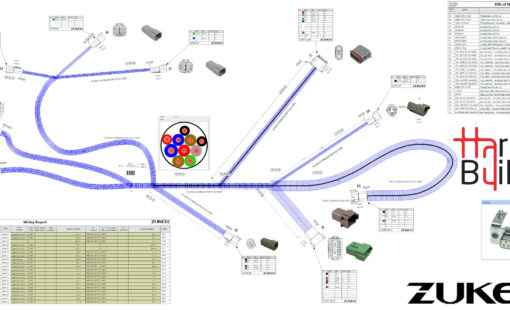

Harness designers and manufacturers are looking to meet the pandemic-led increase in demand with innovative solutions to improve time to market. It is more important than ever to have a streamlined manufacturing process with comprehensive communication of design intent. It is also vital to increase the use of design configurations to eliminate rework. Harness Builder 2021 for E3.series is introducing ground-breaking features to improve the entire wire harness design-to-manufacturing process. The user community’s requirements and significant industry trends are the primary driving forces behind the new features and enhancement.

Harness Builder for E3.series is the leading cutting-edge solution for wire harness manufacturers for taking a wire harness from concept to manufacturing. The wire harness designers are empowered to simplify the quoting process, improve quality with design rule checks, automate harness documentation, and drive automated manufacturing processes.

The latest updates are helping teams adapt to new technologies and trends while avoiding rework and manual processes. Harness Builder 2021 for E3.series boasts a long list of new features and enhancements. We are discussing the most impactful features for the design-to-manufacturing process improvement.

- Work instruction assistant

- Dash number configuration management

- New options for automated harness testing and wire processing machine

Work Instruction Assistant

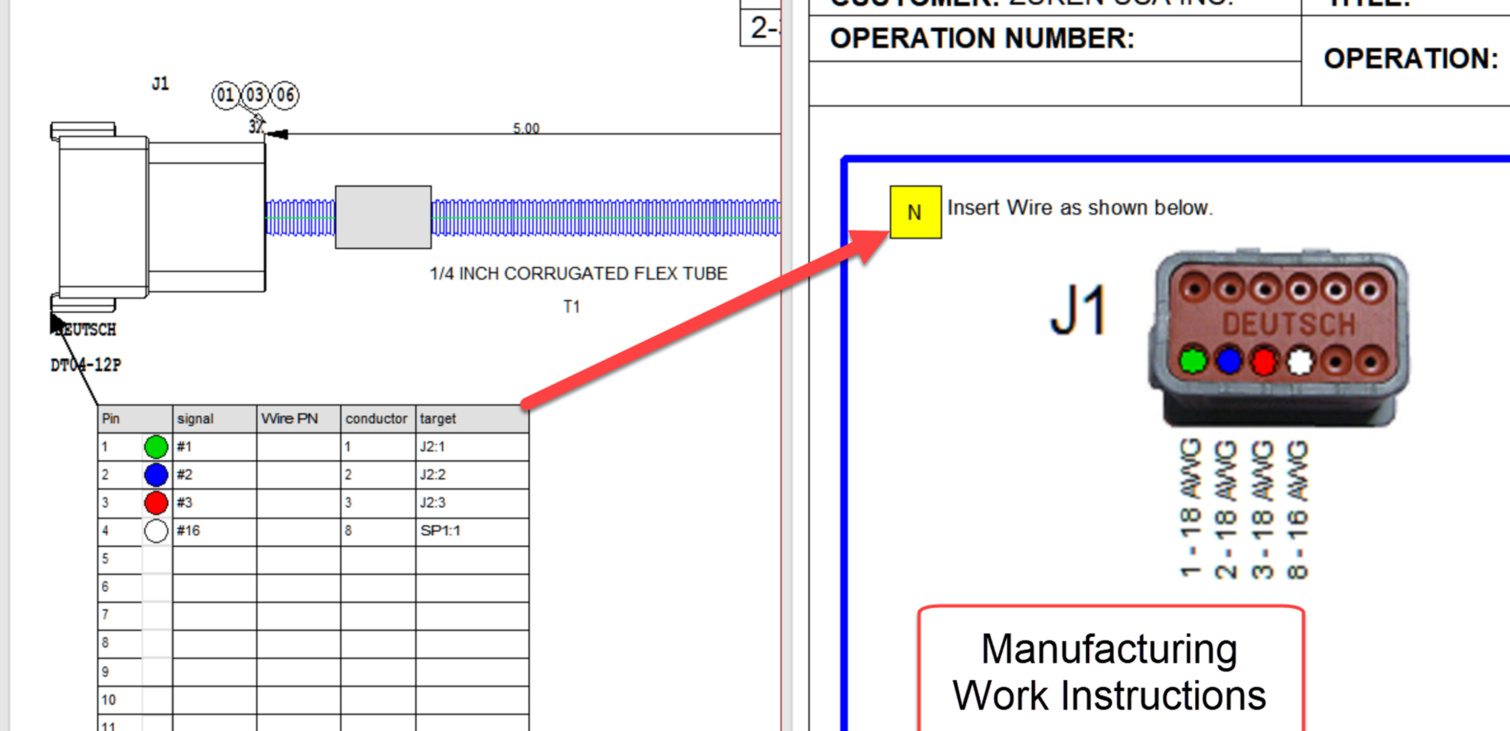

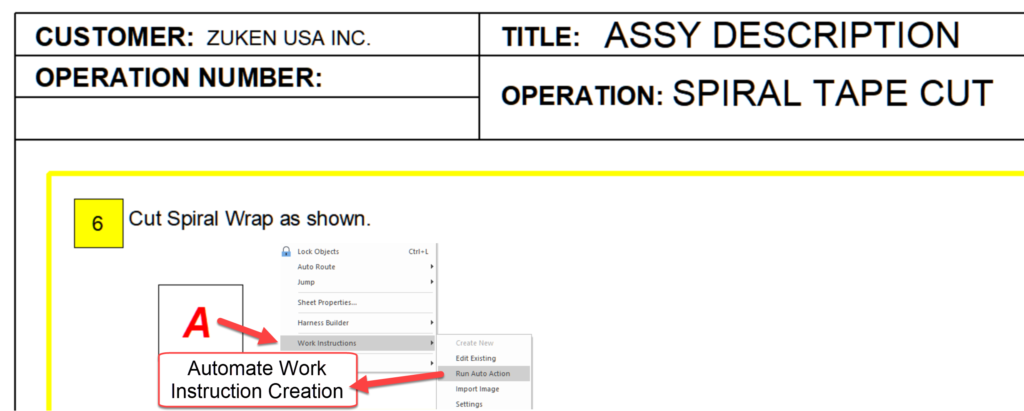

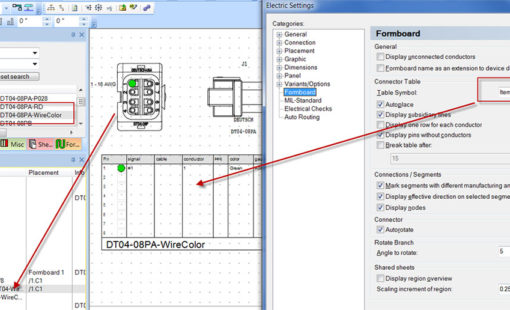

The manufacturing and assembly team requires as much information as they can get in the simplest form to create the harness efficiently. However, creating and managing work instructions is a massive overhead for the design team. Working in sync with industry partners, the design team at Zuken is introducing a semi-automated process for creating work instructions. In Harness Builder 2021, the work instruction assistant reduces the time to develop manufacturing and assembly documentation. Moreover, the quality of manufacturing documentation improves dramatically by using engineering data to drive the work instructions.

Work instructions vary widely across teams, parts, applications, and assembly techniques. On the other hand, completely automating a highly customizable process adds undue complexity. So, the work instructions assistant in Harness Builder 2021 focuses on simplifying the process by providing controlled automation. As a result, the work instructions assistant is a customizable mix of templates, standards, and triggered automation sequences.

Using the work instruction assistant starts with defining templates and automated action within the defined templates. The work instruction assistant augments the process by automating the most time-consuming tasks as and when required. Notably, the users trigger the automation with the help of placeholder elements. For instance, a predefined auto action will insert connector views, wire tables, and other artifacts based on the set-up of the template. Moreover, since multiple templates are available, the format and data may vary based on project criteria.

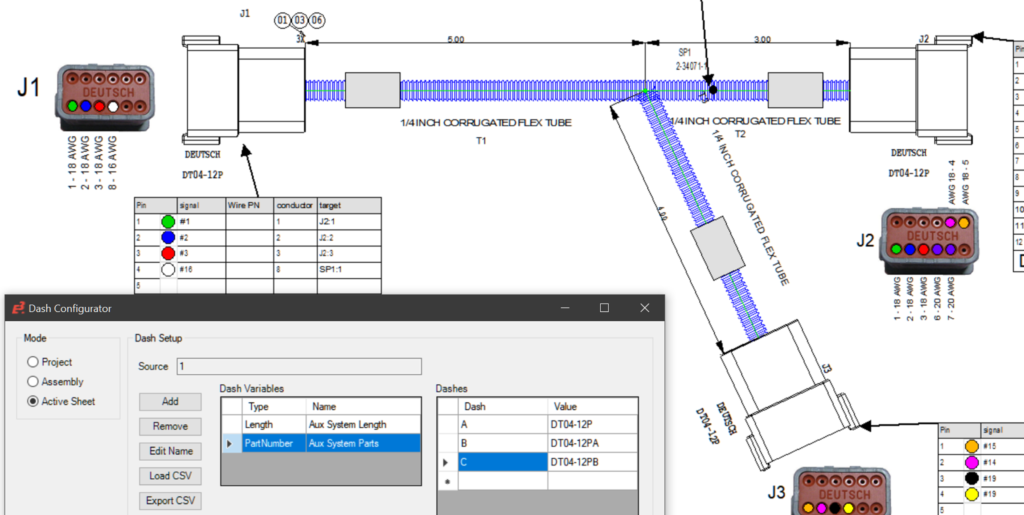

Dash Numbers Configuration Management

Harness Builder for E3.series 2021 introduces Dash Number functionality to improve modular design management of a harness. It is now possible to capture multiple variations of a harness derived from an original design. As a result, design teams save time by eliminating the need to draw many permutations of the wire harness to represent minor changes. Configuring dash numbers is done in three easy steps. Firstly, define the dash number variables and options. Secondly, add parts numbers or lengths to the dash numbers under the variables. Significantly, the dash numbers under the dash variables combine the part number and wire length variations to produce various configuration options. Finally, easily select multiple segments and parts to apply the dash variables.

The dash numbers have a significant impact on the structure and content of the harness version. So, the application derives the bill of materials for all defined permutations of the wire harness. The report captures each dash variation in separate sheets in an Excel file. The Excel files also include a summary sheet providing a quick overview of all dash number configurations in the harness project. As a result, identifying the variations in the report format is quick and easy.

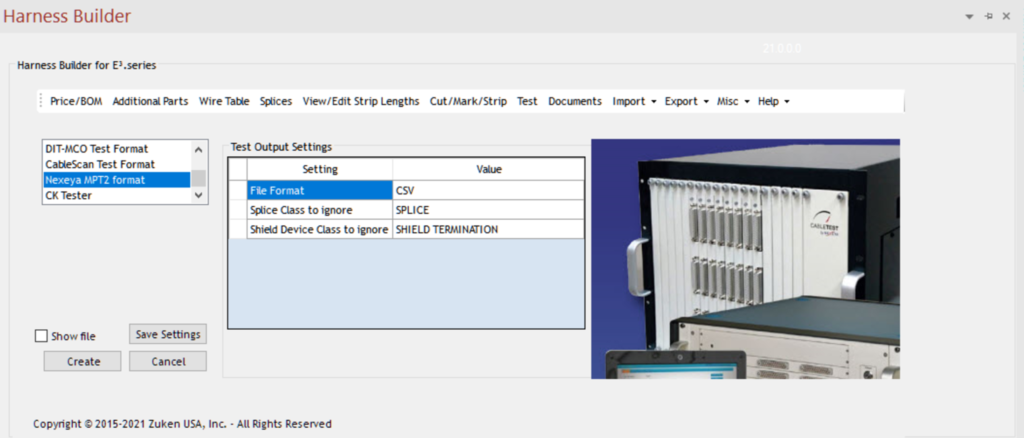

Harness Testing and Wire Processing

Harness Builder 2021 is expanding the list of supported automated wire harness testing machines. The application now supports the export of wire harness design data for two new device families.

- CKT Technologies

- Nexeya MPT2 Tester

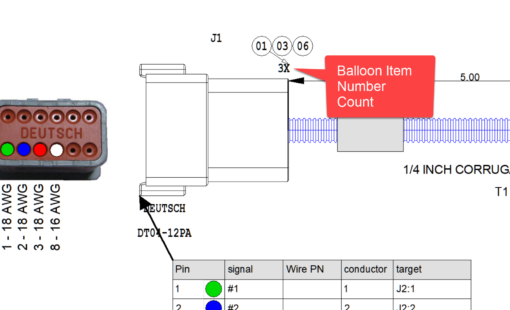

The latest enhancements support more variations and customization options with DIT-MCO and Cirris wire harness testing machines. For instance, the exports options include the multipoint splicing information for DIT-MCO machines. Similarly, the wire processing machines now support new customization options to enhance the manufacturing process further. The update to the reporting process adds more options and customization paths for bills of materials and wire lists. The inclusion of wire assembly information, dash numbers, balloons with item number quantity, and unit of measure improvements together help create a robust design-to-manufacturing workflow.

Other updates include

- New customization options for on-sheet and Excel reports

- Enhanced import from/to Excel

- Simplified item number visualization with quantity on balloon numbers

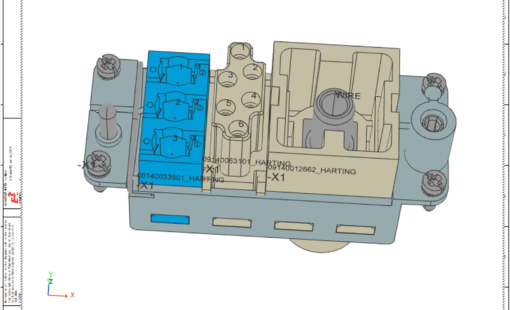

- New plugin and enhancements for ProjectionWorks augmented assembly systems

- The wiring reports are more comprehensive, with HLA and LOC options available for Excel and on-sheet display.

In summary, Harness Builder 2021 for E3.series improves quality and boosts productivity with purpose-built design-to-manufacturing features. Creating manufacturing documentation and instructions from engineering data saves time and improves quality. The use of automated templates creates a simple, customizable, and repeatable process. As a result, it is easier than ever to match customer-specific requirements without rework. Furthermore, the modular harness management option with dash numbers reduces the complexity of managing multiple harness variations. Most importantly, the new features combine with the existing intelligent parts database, 1:1 scale drawings, design rules checks, automated design tools, and outputs for automated testing, assembly, and manufacturing platforms to provide a significant competitive advantage.

For more information about Harness Builder for E3.series, visit our website.

Related Products & Resources

- Products

- Products

E3.series 2021 from Zuken delivers enhancements for connector handling, 3D control cabinet design and ECAD/MCAD collaboration.

- Press Release

Harness Builder 2020 for E3.series reduces time to manufacture and improves design accuracy with new features for auto-placement of labels, entering pre-defined cable lengths, cable tolerancing, and additional support for third-party testing and manufacturing equipment.

- Products