E3.WiringSystemLab

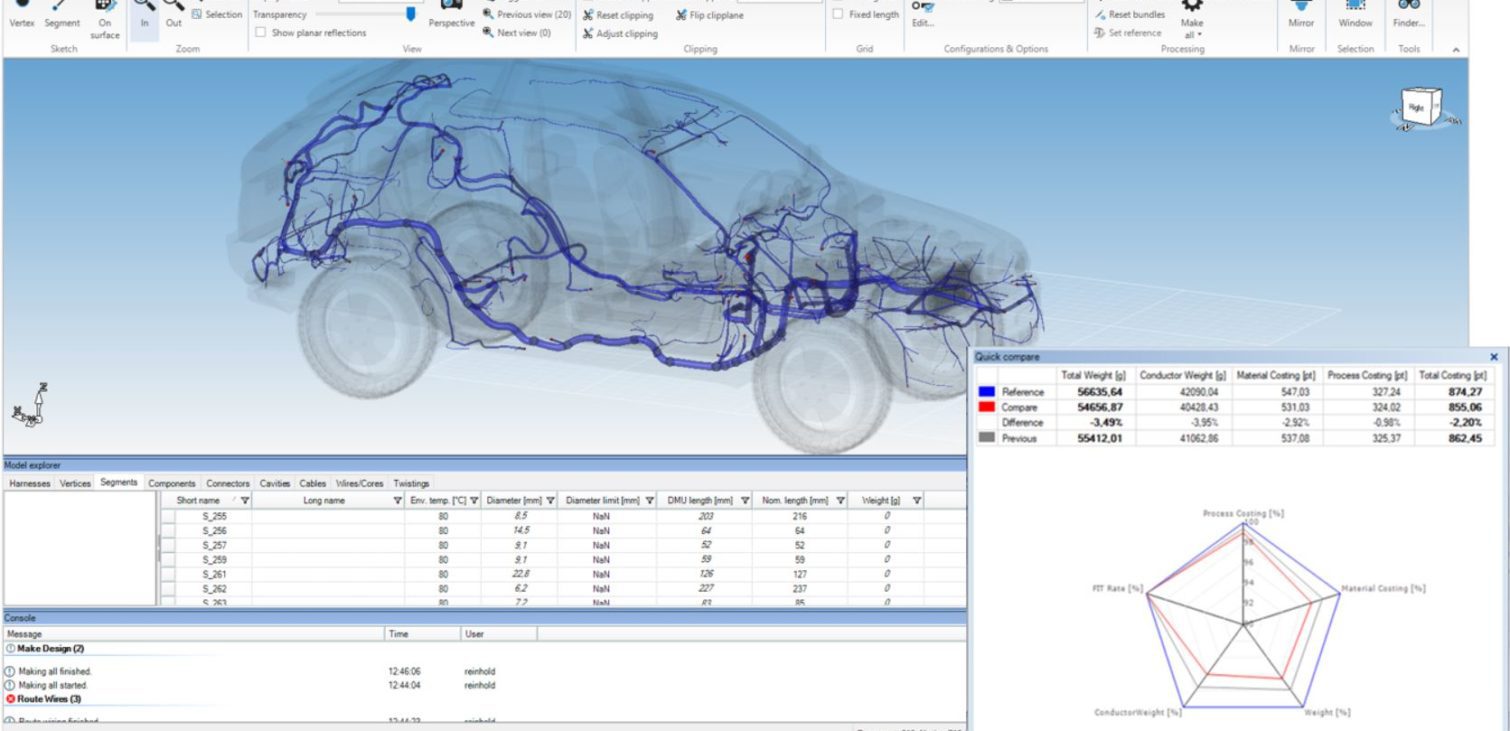

Wire harness design and optimization (for minimum weight and cost) in 3D

Optimizing wire harness designs to meet targeted weight and cost objectives is a complex and challenging task. One of the most time consuming aspects is the consolidation of different data sources and inputs into one consistent representation. Topology data, in particular, have been known to require an intense effort for consolidation, as different segments have to be combined to a single representation and then routed manually in a 3D environment (e.g. CATIA® or Siemens NX®). Zuken’s innovative E3.WiringSystemLab simplifies this complex task with direct 3D data modelling capabilities and automated wire harness assembly functionality supporting the compilation of comprehensive harness designs from heterogeneous fragments. The result is a substantial reduction of ramp-up and optimization cycles.

Special functionality in E3.WiringSystemLab

- E3.WiringSystemLab enables comprehensive wire harness analysis and optimization within a true 3D topology

- Ease-of-use through the familiar MS Office® user interface

- Support of standard formats such as KBL, VEC, PLMXML or Excel® ensures easy integration into CATIA® or Siemens NX® environments

- Seamless integration into E3.series with direct integration into E3.schematics and E3.cable

- Knowledge-based determination of weight and cost using AI-methodologies

- Representation of different variants and configurations within a single project enables evaluation of different implementation approaches

- Powerful analysis and compare functionality to quickly determine the most suitable solution

- Results can be transferred directly into production development environments