Connect with Zuken to see how E3.series can strengthen your design-to-manufacture workflow. Try our guided E3.series Test Drive to experience the value firsthand.

Menu

A persistent divide often exists between design engineers and production teams. Particularly in the field of electrical systems engineering. Designs that appear flawless in theory frequently require substantial modifications once they reach the shop floor. This disconnect is especially evident in wire harness and control cabinet manufacturing, where wire harness design accuracy becomes critical and practical constraints frequently challenge theoretical assumptions.

While a schematic or cable plan may appear sound from a design perspective, seemingly minor omissions – such as unaccounted-for internal wire lengths within connectors or the inappropriate selection of mating components – can result in significant complications during the transition to production. These can manifest themselves as assembly delays, increased material costs, or system incompatibilities that compromise product integrity.

This article explores common pitfalls in wire harness design and demonstrates how E3.series effectively addresses these challenges to enhance accuracy, reduce rework, and foster greater alignment between design and production.

Wire Length Errors and Their Impact on Design Precision

Wire length calculation, although often considered a straightforward task, is prone to error when critical factors are overlooked. Conventional design methods frequently omit the routing paths that wires follow inside connector housings, often because this data is difficult to represent manually or must be estimated using scripts. Moreover, these methods tend to disregard the spatial complexity of three-dimensional cabinet or harness environments, where wires must traverse over obstacles or curve along structural features. Additionally, allowances for practical requirements such as service loops, bend radii, or termination slack are often applied inconsistently, leading to designs that fall short in production.

Such oversights can result in wires that are too short to terminate properly or excessively long, creating a need for manual adjustment and rework. These interventions not only extend assembly times but also introduce variability that compromises process reliability. The challenges described here underscore the need for a more automated, geometry-aware solution—one that integrates connector internals, 3D path constraints, and pin-level slack directly into the design environment.

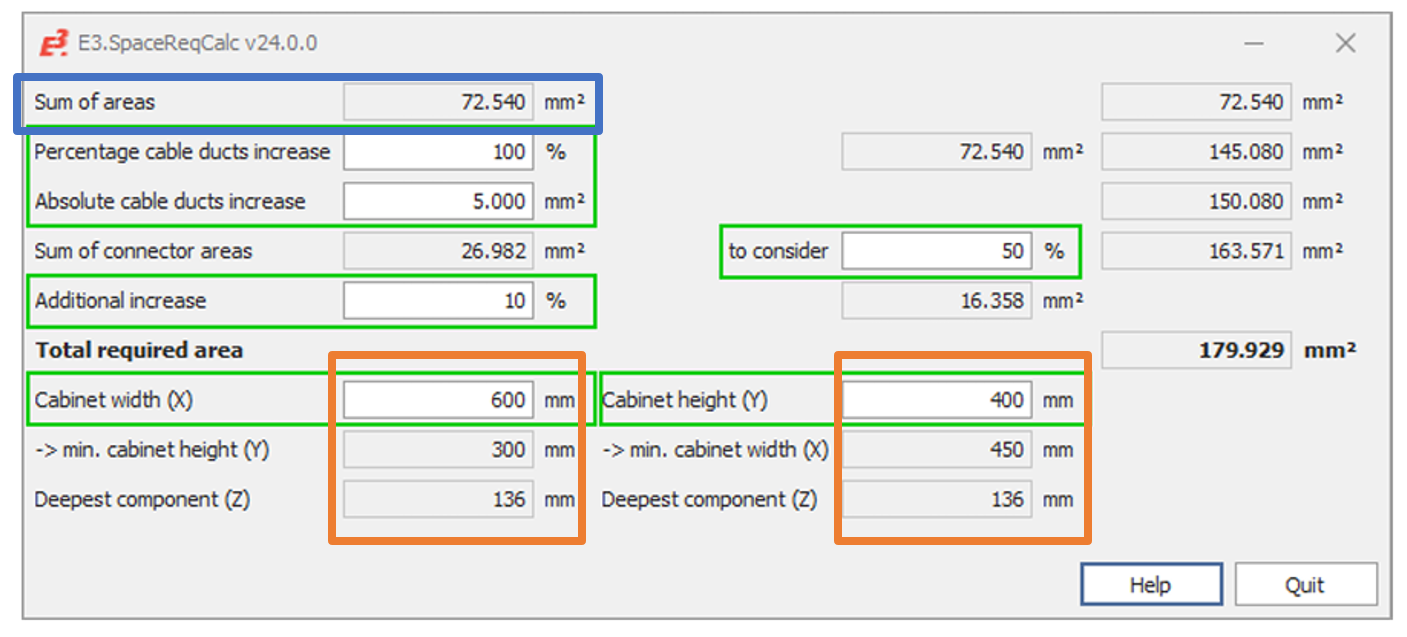

Misestimated Bundle Diameters and the Risk to Design Integrity

Wire bundles, while often treated as abstract representations in design schematics, occupy physical volume and must conform to the constraints of predefined routing channels and ducts. One of the most common sources of error is the underestimation of bundle diameter due to the use of nominal wire sizes without consideration for insulation thickness, shielding, or cable type. When these factors are overlooked, bundles may exceed available duct space, resulting in thermal issues, signal integrity problems, or the need to re-engineer the layout during installation. Addressing these concerns requires a system that can dynamically calculate and verify the physical space occupied by wires based on precise component metadata and current routing conditions.

The Accuracy Impact of Unaccounted Offset Data

Offset data describes the spatial deviation between idealized connector positions in a schematic and their real-world mounting locations in three-dimensional space. Such deviations often arise from panel inclinations, the presence of door-mounted components, or offset enclosures. In many design tools, these details are captured late in the process or not at all, leading to wire routes that do not reflect physical reality. Without this critical spatial input, designs risk becoming disconnected from actual cabinet constraints, increasing the likelihood of misrouted wires and costly last-minute corrections.

How E3.series Improves Wire Harness Design Accuracy

E3.series includes a set of targeted enhancements that directly address common sources of error in wire harness and control cabinet design. By automating wire length calculations—including internal connector paths and manufacturing-specific slack—the software ensures that measurements are both realistic and production-ready. Enhanced bundle diameter estimation leverages precise part metadata from the ECAD component library, preventing oversizing issues and routing conflicts. Furthermore, E3.series incorporates exact spatial offsets into the design model, enabling engineers to account for complex real-world mounting scenarios from the outset. Together, these features create a continuous digital thread from schematic to shop floor, significantly reducing the need for rework and manual adjustments.

Accurate Wire Length Calculation

E3.series adopts an integrated approach to wire length calculation that extends far beyond basic point-to-point measurements. The system automatically includes routing distances inside connectors based on known housing geometries stored within the component library. This eliminates the need for error-prone scripts or manual adjustments.

Furthermore, engineers can define precise 3D routing paths using vector-based inputs, accounting for the actual wire trajectory through panels and enclosures. Manufacturing-specific allowances such as crimping slack or service loops can also be set at the pin level, enabling full traceability and documentation of total wire length from design to production.

Enhanced Bundle Diameter Estimation

The enhanced bundle diameter functionality in E3.series derives its accuracy from comprehensive part data that includes real wire dimensions, insulation thickness, and shielding characteristics. These values are pulled from the validated ECAD component database, where each part entry is linked to detailed metadata, often including datasheets and manufacturer specifications.

The system aggregates the spatial occupancy of each wire within its designated routing segment, dynamically updating the total bundle size as wires are added or removed. This calculation includes special considerations such as internal connector paths and spacing rules that reflect installation best practices. As a result, engineers receive early warnings if bundle diameters exceed the capacity of ducts or mounting spaces, allowing them to address issues proactively.

Integrated Offset Management

E3.series embeds offset data directly into the component model, allowing users to define exact spatial relationships between devices and their mounting locations. These offsets are not approximations but are assigned with precision, ensuring accurate routing in the final assembly.

This data continuity is maintained across exports to MCAD and manufacturing systems, preserving routing fidelity and supporting advanced automation workflows. By incorporating physical constraints and positional logic into the design phase, E3.series enables a seamless transition from digital model to real-world implementation.

Practical Implications for Engineers and Manufacturers

These enhancements in E3.series 2025 are particularly advantageous for manufacturers working with high-density harness designs, modular assemblies, or compact enclosures where space and precision are critical. By embedding manufacturing realism into the electrical design process, the software minimizes late-stage modifications and enables a leaner, more predictable production flow.

Accurate wire lengths, reliable bundle dimensioning, and exact positional offsets reduce uncertainty, accelerate installation, and improve the consistency of assembled products. These gains are not only technical but also strategic, supporting faster time-to-market and improved cost control.

Conclusion: Ensuring Design Integrity through Detail-Oriented Engineering

Electrical design projects demand a high degree of precision to translate digital schematics into functional, manufacturable systems. The E3.series platform directly addresses critical areas of concern—wire length, bundle sizing, and routing offsets—ensuring that designs move from screen to shop floor with minimal deviation.

By bridging the gap between engineering and production, E3.series enables organizations to deliver higher-quality electrical systems with greater efficiency and confidence.