Article 3 in our series Executives’ Perspectives on Digital Transformation by Yasuo Ueno, Senior Managing Executive Officer and Head of Business Strategy, Zuken Inc.

The digital transformation (DX) has become one of the central initiatives in Japan’s manufacturing sector, driven by a strategic framework set out by the Ministry of Economy, Trade and Industry (METI). This push raises a broader question: What guidance could Japan’s DX strategy offer to European manufacturers facing similar pressures?

Across global industry, companies confront a growing tension:

Are we stuck in a complexity gap, overwhelmed by rising system interdependencies and uncertainty? Or can we instead learn to harness complexity as a strategic advantage?

The concept of Dynamic Capability, the ability to sense, seize, and transform in volatile environments, offers a potential answer. But how can manufacturers put dynamic capability into practice? And what technologies, processes, and organizational shifts are truly required?

METI’s Direction: From Efficiency to Dynamic

Capability

To approach these questions, let’s first look in what direction METI leads us in this respect. The 2020 METI White Paper marked a significant shift in digital technology. For the first time, DX was framed not merely as an IT initiative, but as an essential pathway toward strengthening dynamic capabilities in Japanese manufacturing.

METI argues:

“Digital technology has great potential for enhancing not only the manufacturing industry’s ordinary capabilities, but also its dynamic capabilities. Despite this, many Japanese manufacturing companies view IT investment primarily as improving business efficiency, reducing costs, and updating and maintaining legacy core systems, and it is difficult to say they are making full use of digital technology to strengthen their dynamic capabilities. However, if they can enhance their Dynamic Capabilities using digital technology, it will be possible to maintain, and in some cases even strengthen, their competitiveness, even in a world of high uncertainty. Therefore, strengthening Dynamic Capabilities by making full use of digital technology is the strategy that Japanese manufacturing companies should adopt in a world of high uncertainty.”

These capabilities are comparable to the points raised in the previous article in that companies might have been focused more on tangible, short-term initiatives like increasing their process efficiency and price competitiveness rather than what seemed to be some nebulous transformative capabilities.

This critique is not unique to Japan. Many European manufacturers, too, continue to favor incremental improvements over strategic reinvention, focusing on tangible short-term gains rather than systemic capability building.

If Industry 4.0 asks companies to transform their business models without showing how, it is no surprise that Japanese manufacturers have found it equally difficult to implement.

Digital Transformation in Japan

In Japan, the term Digital Transformation has become far more popular than “Industry 4.0.” Yet its meaning often remains abstract, and many vendors promote their own interpretations. The term is used so widely and so inconsistently that there is a genuine risk of DX becoming a mere buzzword, with the original strategic intent fading from view.

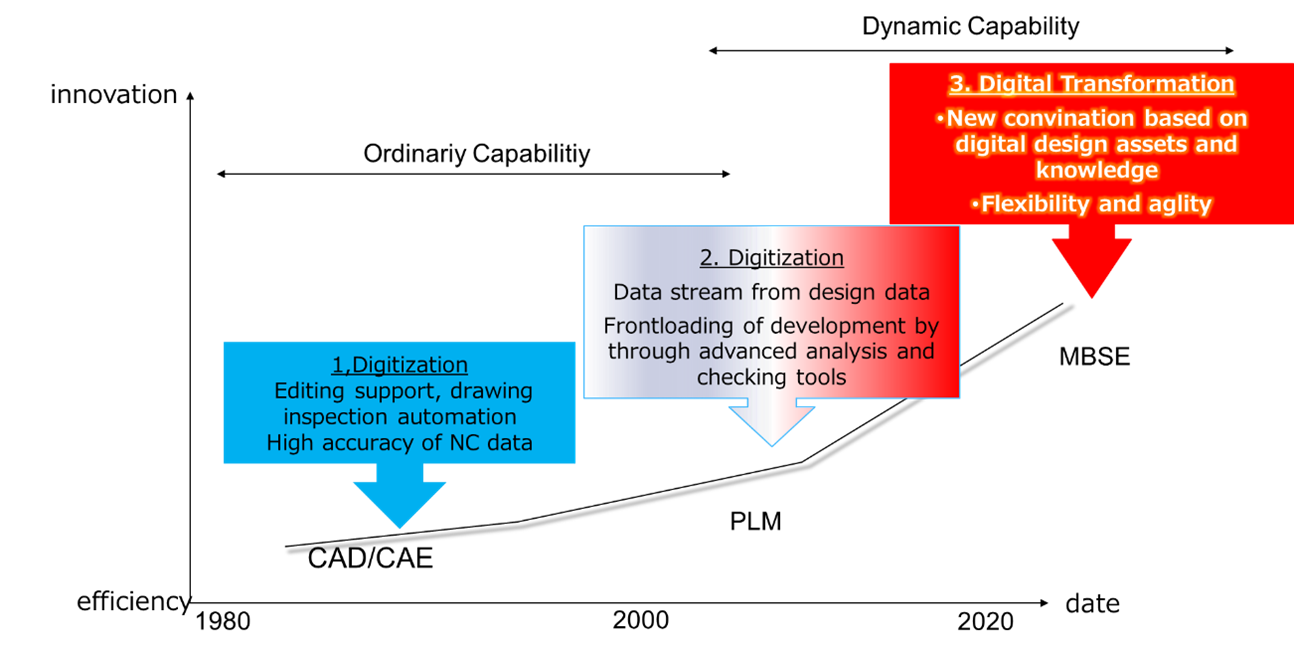

To counter this ambiguity, METI has introduced more concrete guidance through a structured three-step framework: Digitization, Digitalization, and Digital Transformation. This approach provides companies with a clearer, more actionable path toward meaningful change.

The chart links METI’s three DX steps to organizational and dynamic capabilities; the examples of each IT (CAD/PLM/MBSE) are the author’s interpretations to show practical implications.

So far, Japanese manufacturers have managed to cope with rising complexity and the need for agility largely through human expertise and intense manual effort. But this approach is reaching its limits. The increasing scale, interdisciplinarity, and speed of modern product development make it impossible to rely solely on individual experience or fragmented documentation. Now is precisely the moment when IT must step in—not just to automate tasks, but to support and enhance the industry’s capacity for innovation.

This is why I agree with Thomas Gessners thoughts on the model-centric approach, he shared in our previous article of the series. Engineering organizations cannot navigate uncertainty or manage complexity effectively using document-based methods. To make accurate, timely, and high-quality decisions, they need integrated, dynamic models that reflect the true behavior and structure of their systems. For manufacturing, Model-Based Systems Engineering (MBSE) is the only method capable of providing this foundation. It is the essential enabler – indeed, the core – of any meaningful Digital Transformation.

In the next part, I will share more details on how MBSE can be implemented as a central pillar of DX. Thomas and I would welcome your thoughts on these insights and your perspective on the direction European manufacturers are likely to take. Let us know in the comment section below.

Also in this series

- Blog

Executives’ Perspectives on Digital Transformation #2 The Productivity Paradox

- Blog

Executives’ Perspectives on Digital Transformation #1 Building Dynamic Capabilities for Product Success in a Changing World