June 6, 10:00 AM – All Levels

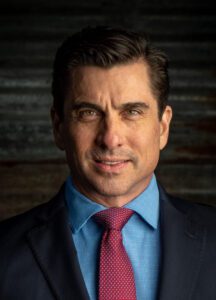

ABOUT DAN THURMON

Dan Thurmon is the founder and President of Motivation Works, Inc. This company helps leaders and their organizations move confidently through change and transformation, so they become, achieve, and contribute MORE.

His clients include Bank of America, Coca-Cola, Delta Airlines, Honeywell, Johnson & Johnson, Kraft, Marriott, Microsoft, Procter & Gamble, Prudential, State Farm, and Walmart.

Dan is an expert speaker and performer. He’s delivered thousands of presentations across six continents for audiences, including world leaders, Fortune 500 companies, entrepreneurs, educators, and even troops on the front lines of battle in Iraq and Afghanistan.

In 2011, he was inducted into the prestigious Speaker Hall of Fame — and is one of fewer than 200 living speakers to have received this honor.

Dan has served as the President of the National Speakers Association. During his tenure, he led the Board of Directors and the 3,000+ member organization through a critical transformation, which included new governance; new mission, vision, and values; higher member value; and greater financial accountability.

He is also a writer and content producer. He’s authored two books: Success in Action and Off Balance On Purpose.

Along with his speeches and books, Dan produces an ongoing, weekly video-coaching series and podcast in which he shares leadership principles and life-enhancement strategies in under three minutes.

Dan and his teenage daughter, Maggie, have become social media sensations on TikTok. Several of their videos have been viewed more than 30 million times, and their personal channel has well over a million subscribers. Maggie and Dan’s creative and enthusiastic content resonates strongly with an audience that spans the world.

Dan built his first company, a live entertainment firm, in the late 1980s to finance his education at the University of Georgia. There, he received his degree in Business. In the mid-1990s, Dan changed his firm’s focus from live entertainment to corporate education, so he could more fully use his knowledge about peak performance and help businesses succeed at a much higher level.

He is a health and fitness advocate. In his 50s, Dan continues to train and perform advanced acrobatics and enjoys hobbies such as golf, mountain unicycling, and flying trapeze.