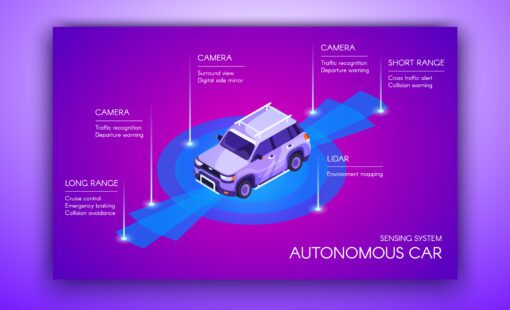

The complexity of electrical and electronic (E/E) systems is accelerating across multiple industries and sectors. Manufacturers are adapting their design and development approaches to meet the changing requirements of advancing electrification.

The automotive industry is a perfect example of this. Manufacturers must now focus on balancing computer and network resources while distributing electronics and software across vehicles. Beyond that, they must also ensure such vehicles satisfy specific form, function, environmental, safety, and user experience requirements. Increasing electrification hasn’t just changed the methods for engineering and manufacturing today’s vehicles. It has also transformed the methods for marketing, selling, and servicing them further down the product pipeline.

Stories like this are common in the transportation sector and beyond. You’ll find them in a range of industries. And we can only expect the evolution of design techniques and procedures to continue as our products get smarter and consumer demand increases.

Borne Out By the Evidence

Lifecycle Insights recently conducted a research study in an effort to understand and quantify the impact of electrification across multiple industries. The Engineering Executives Strategic Agenda Study confirmed what we have heard anecdotally: electrical complexity is increasing and continues to have a substantial impact on engineers.

In this post, I’ll share the findings from this study, including:

- insights into the changing complexity of today’s E/E systems

- the impact this has on our development processes and product requirements

- suggestions to help meet and manage these requirements in a progressive manner

Managing Requirements Traceability in the Face of Rising Complexity

We all know that E/E systems are getting more complex. Yet, the rate of change of that complexity surprised me. Today’s products don’t just need simple E/E systems. The market demands increasingly intricate systems. What’s more, according to The Engineering Executives Strategic Agenda Study, this rising E/E complexity is occurring across multiple domains.

Some 58% of the respondents said the complexity of electrical distribution systems is increasing or increasing greatly. Two-thirds (66%) also said the complexity of today’s electronics systems is increasing or increasing greatly.

So, it comes as no surprise that many organizations are struggling with requirements management and traceability. As E/E systems’ complexity rises, engineers must manage a greater number of requirements inevitably linked to items distributed across electrical, electronic, and software domains.

Our research reveals that “satisfying target requirements, either from customers or competitors” is a key issue for most respondents. More than half (53%) of the respondents cited it as one of the top two challenges they face. This challenge received the highest rating in the study.

Changes are essential across the product development process to stay on top of requirements. But many organizations struggle to track and manage the changes. As I’ve already mentioned, this is partly due to the interconnected nature of today’s requirements.

When you develop a new E/E system, everything must work together. You must make sure electronics on the network use compatible protocols. Then, you must ensure enclosures allow electronics to vent heat efficiently. And finally, you must avoid overloading the network with traffic.

The modernization of E/E systems design doesn’t just affect one aspect of the design. It impacts every area of the product. The rising complexity of today’s E/E systems demand a robust requirements management strategy

Problems with Requirements Traceability in Spreadsheets and Documents

Traditionally, manufacturers manage product requirements by leveraging one of the most ubiquitous solutions available today: spreadsheets and documents. However, when it comes to tracking and managing your requirements under growing E/E systems complexity, such tools have many issues. Let’s examine these issues now.

Version Control Problems

To start, engineers manage changes to documents and spreadsheets at a file level using desktops or laptops. This can cause version control issues.

For example, if you have 50 requirements in one spreadsheet, and the version numbering system of the file changes from 2.1 to 2.2, it is difficult to track what changes have been made to each requirement. You don’t know if just one requirement has changed slightly or whether every single requirement in the spreadsheet has been edited. This makes it difficult not only to monitor changes to the product, but also to revert the changes on a case-by-case basis, if required.

Lack of Collaboration

Using spreadsheets and documents also stymies collaboration. This is because only one person can open the document or spreadsheet file at a time. This adds to the version control problem, and also limits the ability to simultaneously edit and collaborate on the requirements. Because there is no single source of truth, individuals can wind up working with out-of-date information.

Lack of Context

Another issue lies in the inability to directly associate or allocate requirements to different design elements in the system. If you enter your requirements as text in a spreadsheet or document, for example, they cannot be linked to the electronic unit, electrical network, or software module you’re talking about. Engineers don’t know what design elements are meant to fulfill which requirements, causing confusion, and often, costly errors in the final design due to a lack of available context.

Leveraging Model-Based Systems Engineering

A model-based systems engineering (MBSE) approach addresses these challenges. It provides a more progressive way of managing requirements under growing E/E systems complexity.

The basic premise is to have a single model, composed of requirements, functions, a logical architecture, and a physical architecture. Using this approach, you can allocate elements to one another. Requirements are allocated to functions. Functions are allocated to elements of the logical architecture. Elements of the logical architecture are then allocated to different elements of the physical architecture.

Everything is now connected. By creating this network of allocations, you establish clear traceability across the product design, from the top-level requirements all the way down to the physical implementation of the design. This removes ambiguity and allows engineers to clearly understand the function and purpose of each design element, while expediting the development process and increasing cross-team collaboration.

MBSE creates a single source of truth, which allows access and editing concurrently and in real-time, reducing the likelihood of versioning issues and design errors.

In summary, an MBSE approach simplifies the tracking and management of product requirements. This fit-for-purpose requirements management approach allows you to mitigate the rising complexity of today’s E/E systems.

Recap

- While there is plenty of anecdotal evidence to suggest E/E systems complexity has been growing rapidly for years, The Engineering Executives Strategic Agenda Study supports and quantifies this trend.

- The study reveals the complexity of both electrical distribution systems and electronics systems is increasing or increasing greatly (for 58% and 66% of respondents, respectively). It also reveals that the majority of organizations (53%) are struggling to manage requirements in the face of this growing E/E systems complexity.

- Traditionally, spreadsheets and documents are used to manage requirements, but this way of working is no longer fit for purpose. The spreadsheet approach allows change management at a file level, leading to version control issues. This approach hampers collaboration as only one stakeholder can access and edit the document at a time. What’s more, you cannot directly associate or allocate requirements to different design elements in the system using this approach.

- This is where an MBSE approach can help, providing a network of allocations to better manage requirements. From the top-level requirements all the way down to the physical implementation, MBSE provides the level of traceability and visibility required to increase collaboration, reduce errors, provide context, and effectively deal with rising E/E systems complexity.

For more information about MBSE, systems engineering, and digital engineering visit our website, or read more digital engineering blog posts here.

Also see:

Related Products and Resources

- Products

The Digital Thread is a foundational element of a successful Digital Engineering implementation. Digital conversations involving procurement, design, manufacturing and field service replace email and paper documents. Decisions and rationale are captured and provide traceability.

- White Paper

This eBook describes an MBSE based process for Electrical and Electronic design. The eBook begins with model content and structure with the purpose of implementation and the need for a “design envelope”.

- Products

Digital Engineering requires a model-based design process that begins in Systems Engineering. Zuken acquired Vitech Corporation, a leader in Systems Engineering practices and MBSE solutions, with the intent of implementing an E/E model-based design process.

- Products

Digital Engineering requires a model-based design process that begins in Systems Engineering. Zuken acquired Vitech Corporation, a leader in Systems Engineering practices and MBSE solutions, with the intent of implementing an E/E model-based design process.