As engineers face increasing complexity across electronics and electrical systems, they need a single set of related data to offer insights into the product’s various processes and functions. Simply stated, they need a digital thread for electrical systems.

What is a Digital Thread?

You’ve likely heard this term. But the digital thread is more than just a hot new industry buzzword. This unique communication framework enables a connected data flow. As a result, you get a holistic, integrated view of a product’s data across its components—and the lifecycle.

The digital thread offers easy access to data previously held in silos. The siloed approach made it challenging to retrieve and analyze that data for smarter decision-making. The digital thread benefits the entire team, and many are now recognizing the importance of prioritizing it in product development.

So far, this concept has been applied mainly to the development of mechanical hardware. Mechanical engineers increasingly see the value in this kind of data-sharing framework. But the digital thread is also applicable to electrical systems and electronics. Let’s talk about some of the digital thread’s key characteristics and what they offer to the development team.

Interconnected Artifacts

A digital thread offers a way to connect a design’s various representations across engineering domains and functional departments. One key trait of a true digital thread is its ability to track relationships between different design deliverables.

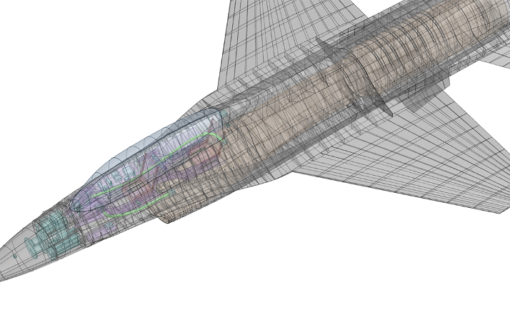

For example, a mechanical hardware component will be represented in three-dimensional geometry. That same representation also appears in the 2D drawing and assemblies. The digital thread understands these deliverables are interrelated and it can help you ensure the propagation of changes across such artifacts.

It’s easy to see how this digital thread function also applies to electrical and electronic systems. Your logic diagram, PCB layout, and 3D assembly of the board subsystem essentially represent the same thing in electronics. If you change one of these representations, then you often need to make that change to many of them. A digital thread helps you track and propagate such changes to every level of design.

As in the case of mechanical hardware, the digital thread allows everyone to understand relationships and how changes influence the system as a whole. Everyone can stay on the same page when it comes to design. This is especially valuable during the chaotic work-in-progress phase of the design cycle.

Revisions Over Time

Engineering, at its essence, is a process of iteration.

Iterative design allows engineers to quickly create and test new ideas. They can identify issues before companies spend too much time or money on them. Try one thing, see it fail, and learn from it. Try another thing and see it succeed.

Finding the right design is a meandering path. In the process, you gain novel insights into how each aspect of your design performs both individually and in context. Then you can find solutions that meet all of your requirements thoughtfully and cost-effectively.

The digital thread is a powerful tool for the iterative design process. By managing this digital thread, engineers can track different versions of evolving design artifacts over time along with the discussions and decisions that got you there. But, perhaps equally importantly, the digital thread also records how interconnected design artifacts relate to different versions of one another.

Then everyone can see, first and foremost, what the latest and greatest set of design artifacts are. But it also allows your team to understand what the latest set of design artifacts were at a prior date. The digital thread presents a complete historical record of how all the components of your design—even those with complex, interconnected relationships—reference one another.

Does this apply to electrical systems and electronics? Of course, it does. With a digital thread, all participants in the design process know they are looking at the most up-to-date diagram, layout, or board assembly. When everyone is on the same page, making informed decisions about the next steps is easier.

Managing the Digital Thread: What are You Doing Today?

Whether you realize it or not, you are already managing a digital thread. You already track how your different design artifacts affect other pieces of the system. To do that, you need to be able to track different versions of those design artifacts as they mature and evolve.

To assess the value of your tracking process, you should consider several questions:

- Do you have the right processes and technologies in place to communicate the state of those artifacts to the people who are not actively working on them right now?

- Do you have the ability to share the latest status of the design with other engineers?

- Can you share it with others in your company who haven’t had direct interaction with the individuals designing those artifacts?

- Can you provide design process insights containing enough detail for members of your organization to reasonably make decisions about the next steps?

If you answered “no” to any of these questions, there is good news: You can improve how your organization is managing the digital thread.

Building and maintaining this vital communication framework empowers everyone in the organization, from the engineering design team to the C-suite. It provides a consistent way to share the full context of your design—as well as its current state. So everyone involved can make smarter, better, and faster decisions.

Recap

- The digital thread is more than just a hot industry buzzword. It’s a unique communication framework that provides an integrated view of a product’s data flow across its different component parts and across its life cycle. Historically, the digital thread has been used in mechanical hardware design. But it is also useful in designing electrical systems and electronics.

- The digital thread connects a product’s processes and functions and offers engineers a way to track system changes over time. When talking about the design of an electrical system, your logic diagram, formboard layout, and 3D model should all represent the same thing. The digital thread can help ensure you propagate any changes to all levels of any complex design. Thus, saving you and your team time and angst later.

- The digital thread also provides great value to the iterative design process by tracking different versions of evolving design artifacts over time. It also tracks how interconnected components relate to one another and how any changes to one artifact may influence another. When you consider the design process over time, the digital thread provides a complete historical record of your design. You and your team can refer back to it at any time as needed.

- You are likely already working with some sort of digital thread. However, you may not even be aware of it. Even if you are, you may not be using the most up-to-date technologies and processes to help you manage it with ease. Whether you are designing mechanical hardware or electrical systems, managing the digital thread is becoming an integral part of the design process. You have an opportunity to improve your organization’s management of it, maintaining this vital communication framework to empower decision-making across the enterprise.

—–

For more information about MBSE, systems engineering, and digital engineering, visit our website or download our Digital Engineering eBook.

—–

Related Blog Posts & Resources

- Blog

- Webinar

This webinar will discuss the relationship between systems engineering, digital engineering, and MBSE in creating the framework we need to deliver complex products.

- White Paper

This eBook describes an MBSE based process for Electrical and Electronic design. The eBook begins with model content and structure with the purpose of implementation and the need for a “design envelope”.