Last year we started working with Zuken using E³.series electrical CAD software for our Formula Student team ‘Rennstall Esslingen‘ at the University of Applied Sciences Esslingen.

The Formula Student initiative is a worldwide program that has been designed to encourage and develop the automotive engineers of tomorrow. Multi-disciple student teams design and build race cars and drive them in competitions around the world.

More about the team

The project is structured as a small business with project management. At the Esslingen team, this consists of three students who are responsible for the engineering, production and organization. On the technical side there are two project managers, one for engineering and another for manufacturing who are on hand to specifically look after the propulsion, electronics, body, chassis and the styling of the new race car. The team is completed by project groups that work on this as part of their studies focusing on individual components through to assemblies.

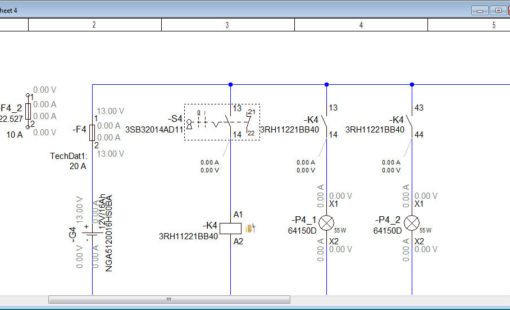

In the 2011 season, four research groups from Rennstall Esslingen are represented in the racing team working on the electrical circuitry, regulated water pump and fan, power supply, controllers, telemetry and data loggers, electrical systems, sensors and power electronics. There are a total of 22 students in the degree programs that together take care of information technology, mechatronics and electrical engineering to the electronics in the new racing car.

Stallardo ’11

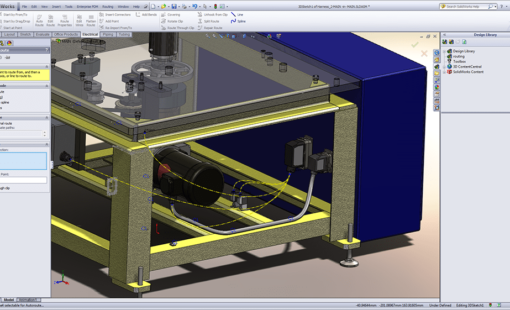

The latest version of the race car will be presented to the public in May and will feature even more complex electrical integration onboard than ever before. Zuken has worked closely with the electrical system group to help them achieve this through software and training.

Application of the software

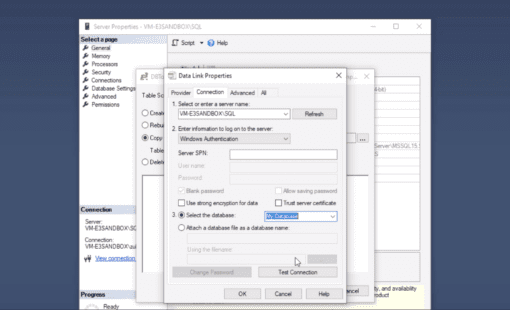

In the weeks after the training, the three team members Florian, Andreas and Abedin, began drawing up the harness for the 2011 race car. This is not yet completed, since important information must be supplied by the other electronic project groups. Once the team get this data, using the E³ Routing Bridge they will be able to complete the harness design factoring in the CATIA V5 mechanical data. Being able to integrate the wiring harness data in CATIA V5 brings many benefits.

These include:

- The ability to create integrated electrical and mechanical BOMs

- The capability to define line lengths in the schematic

- Automatic creation of documentation

- Easier harness production based on the Schematic data. The schematic can be copied 1:1

Rollout of the Stallardo ’11

At the moment, the Stallardo ’11 currently mostly exists on paper. But in less than three months, the students will celebrate with their professors, sponsors and friends, by presenting their latest racing car.

So there is a lot of work to be done between now and May!

Schedule for 2011

After the production of the car, the team will not stop. They will continue to work hard to refine and test the car in preparation for the first international race of the season in early August at the Hockenheim Ring. For four days, students work hard to present their overall approach – it’s not just about the results from the track!

The competition is scored based on a business presentation, cost report and engineering design along with the dynamic disciplines that include acceleration, skid pad, autocross and endurance. On the 6th and 7th of August, the whole team will be working hard to convince the judges that they deserve a top place at this event.

Another highlight for the Esslingen team will be the Italian event hold at Riccardo Paletti Circuit in Varano de ‘Melegari on the 2nd – 5th September. The aim is to once again prove that the Rennstall Esslingen is one of the best teams in the world and improve upon the world ranking of 16 (out of 476) from last year.

This guest post was written by Aleksandra Damjanovic a member of the Esslingen University Formula Student team.

Related Products and Resources

- Products

- Products

- Products

- Products

E3.series is a Windows-based, scalable, easy-to-learn system for the design of wiring and control systems, hydraulics and pneumatics. The out-of-the-box solution includes schematic (for circuit and fluid diagrams), cable (for advanced electrical and fluid design), panel (for cabinet and panel layout), and formboard (for 1:1 wiring harness manufacturing drawings). Integrated with MCAD, E3.series is a complete design engineering solution from concept through physical realization and manufacturing output.