Cross-functional productivity and quality improvements go hand in hand, it would be a hollow victory to achieve one without the other. Organizations struggle with figuring out where to start amongst the myriad of seemingly endless ‘square ones’. The problem, albeit challenging, is worth solving once you realize the return on investment is huge. The common fallacy is to try to do mechanical design, electrical design, and data management all in one tool set or worse yet, use the best mechanical design tools out there and hope that the quality of the other tools doesn’t matter. It is akin to using a hammer to open a lock, you can do it but a key would be so much easier. Talking about easier, I covered ease of use and time savings in my previous post – you can find it here if you haven’t read it yet – Top 10 Part 1

Simple is always better

The solution is quite simple: pick the best tools for their respective verticals and make sure they have the ability to connect to multiple solution providers. This approach ensures that you do not sacrifice on the quality or productivity while ensuring cross-functional / cross-domain interoperability. Just make sure you have access to a good robust API to customize the solution for those niche requirements you will invariably come up with during implementation.

Zuken strongly believes in creating partnerships for success and that clearly shows in the development principles of E3.series software. E3.series confidently sits in the top tier of electrical and wire harness design software because of its ability to connect with so many solutions out there – PLM, ERP, mechanical design solutions, electrical equipment manufacturers, and assembly automation providers, to list a few. We will discuss the E3.series API in Part 3, which will give you a good picture as to ‘why’ the partnerships are possible, but today, we will be discuss 6 enhancements in more detail.

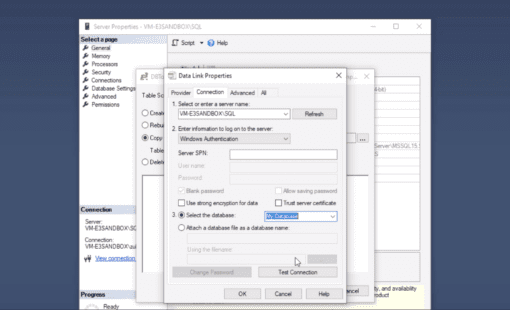

Electrical Data Management with DS-E3

The DS-E3 solution is one-of-a-kind in the sense that it does not talk about managing your entire life but rather provides a robust platform for electrical project data management with connectivity to other higher level PLM systems.

The bigger systems are not adept at managing the nuances of your wires, pin terminals, and other miscellaneous parts that are essential for a complete design. They don’t generally understand that a relay may have 1 coil controlling 2 or more contacts or the ability to keep track of the relay in case you need to change it.

DS-E3 works right inside E3.series to provide easy access to the data needed to make design decisions and connects with other systems to enforce consistency across the board. If you want to learn more about DS-E3, connect with us for an in-depth discussion.

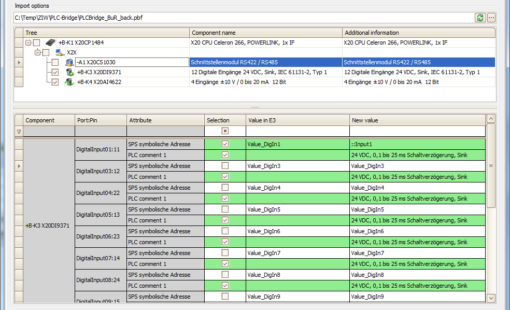

PLCBridge Connectivity

E3.series has enhanced connectivity with automation leaders B&R Automation and ABB. This connectivity helps designers share data between PLC configuration /programming platform and the electrical schematic to reduce rework, increase productivity and overall quality.

The 2017 release expands this relationship with other vendors as well as improves the ability to interact using AML format. The AML import/export capabilities bring major PLC manufacturers like Siemens, Lenze, Phoenix Contact, Mitsubishi Electric, Murr Elektronik etc. into the sphere of interoperability.

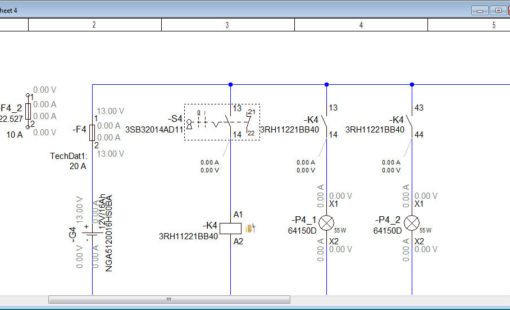

Enhanced Panel Design with Ducts and Rails

Panel design, although a very good contender for 3D design, has predominantly been stuck in the 2D design space. Simply put, most electrical design platforms cannot handle 3D inside the same platform as the schematic, which is always in 2D. I don’t know about the rest of you, but I find a full-fledged 3D mechanical system resonates at a different frequency compared to my brain (not efficient). Yes, I can work in 3D, and I have, but it always feels more of an out of body experience than something that comes naturally.

E3.series panel switches between 2D and 3D seamlessly, making it extremely easy to design in 2D and only go to 3D for the things that need to be done in the 3rd dimension. The new ability to now add ducts and rails at any angle and orientation takes the capabilities to a whole different level. In short, if you can build it then you can design it in E3.series panel.

The automatic wiring feature inside E3.series panel is also amazing and works with the new rails and ducts. I often use it to make sure I have the best part placement to reduce the length of wires, and more importantly to reduce the size of the wire ducts and bundles to maximize space. The added advantage of knowing if the door will close on the panel is priceless. The lesson I learnt from the time I used a contactor with the auxiliary mounted on the front face rather than the typical top mounted auxiliary. The blow back from that incident was bad enough to make me check all dimensions very carefully on every subsequent design.

ATA Standard Wire Numbering

The wire numbering standards in the aviation industry are more stringent and different from the regular industrial machine and automation industry. Instead of the commonly used “Drawing Number + Row + Counter” for unique wire numbering, the ATA wire identification code can be quite involved; the image below shows an example.

The wire numbering standards in the aviation industry are more stringent and different from the regular industrial machine and automation industry. Instead of the commonly used “Drawing Number + Row + Counter” for unique wire numbering, the ATA wire identification code can be quite involved; the image below shows an example.

Designers spend precious time manually numbering wires in an extremely time-consuming and error-prone process

E3.series 2017 automates this process completely and is able to achieve this because of the following inbuilt abilities:

- The ability to have separate counters for the various unique identifiers required for completing this numbering pattern. The software takes care of the multi-level counters and segments, all you have to do is design.

- Wire and connection information is inherently understood and tracked by E3.series automatically.

- All information is up to date all the time regardless of where the change is made in the project.

The biggest reason for this comprehensive wire numbering ability is the fact that E3.series is uniquely aware of design intent and understands signals, wires and devices very intricately.

Automatic Wire Seals

For quite some time E3.series has had the ability to select ‘connector pin terminals’ or contacts, or terminals automatically based on the connector/device you are using as well as the wire you used to make the connection. A 12 gauge wire needs a different insert than a 20 gauge wire – E3.series understands that little detail all the time.

Introduced in the 2017 release is the ability to go further and select wire seals automatically based on the size of the wire. This is a new type of part that can be declared in the library giving you the ability to set this up as a standard in your company and have E3.series take care of it automatically for you.

The auto-selection process is intelligent, taking into account the number of wires being terminated and their cumulative size based on the each individual wire detail.

This is going to be a big time saver, letting you design while the nuances are taken care of by the software. What do you think, will this save you time?

Advanced Terminal Management

Terminals are uniquely simple and complicated at the same time, perhaps the most perplexing of items to manage in the entire design. They are used for simplifying designs, making connections modular and easier to manage. The terminal manager in E3.series already made it easy to manage, add and change terminals. It also gives you the ability to connect to terminal vendors’ pre-configuration modules and produce live detailed terminal plan reports.

E3.series 2017 makes it even easier than before to manage your terminals within the schematic and the panel as well. It is now possible to use the design intent captured in the schematic to

- Merge terminal strips and convert them into a multilevel terminal.

- Sort all terminals with just 1 click rather than doing them individually.

- Place terminal strips in groups rather than 1 at a time.

- Connect to terminal strip vendors to get pre-arranged terminal patterns.

Join me next time as we discuss the amazing Application Programming Interface (API) and show you the importance of an open system.

We want to hear from you on how these enhancements help you and about other areas we can improve to make your lives easier.

Join the Zuken User Community in the US for discussions, videos and much more. For other regions join our Zuken E3.series Users Network on LinkedIn.

Related Products and Resources

- Products

- Products

- Products

- Products

E3.series is a Windows-based, scalable, easy-to-learn system for the design of wiring and control systems, hydraulics and pneumatics. The out-of-the-box solution includes schematic (for circuit and fluid diagrams), cable (for advanced electrical and fluid design), panel (for cabinet and panel layout), and formboard (for 1:1 wiring harness manufacturing drawings). Integrated with MCAD, E3.series is a complete design engineering solution from concept through physical realization and manufacturing output.